Laser Cutting Car Badges

What are Car Emblems? Why Laser Cutting?

A car badge, also known as an emblem or logo, is a decorative symbol or design typically placed on the exterior of a vehicle. It represents the brand, manufacturer, or model of the car, serving as an identifying mark. Car badges are often made of metal or plastic and are designed to be durable and weather-resistant. They can vary in size, shape, and design, ranging from simple and minimalistic to intricate and detailed. Car badges are an important visual element that adds a distinctive touch to the car's exterior, contributing to its overall aesthetics and brand recognition.

Laser cutting offers unparalleled precision, versatility in materials, customization capabilities, fine detailing, consistency, efficiency, and durability when creating car badges. These advantages make laser cutting the go-to method for producing high-quality, visually striking, and long-lasting badges that add a touch of distinction and branding to vehicles.

Video Display | Laser Cut Plastic

Are you wondering if plastic can be laser-cut? Concerned about the safety of laser-cutting polystyrene? Confused about which plastics can be laser cut? Don't worry! In this video, we've got you covered with a complete and detailed guide on safely laser-cutting plastics.

One of the standout advantages of laser-cutting plastic is its remarkable precision. That's precisely why many car manufacturers rely on laser cutting machines to cut and engrave plastic components, including the removal of sprue gates—a common application in the process.

Why Use Laser Cutting Machine to Cut Car Logos?

Ensuring high-quality results is crucial, particularly for products with significant value-added features like medical appliances, gears, sliders, car bumpers, and more. We understand the importance of safety, and that's why many laser factories equip their machines with fume extractors. These devices efficiently absorb and purify any toxic fumes generated during the hot-cutting process, providing a safe working environment.

What to Expect when Laser Cutting Car Symbols

- Precise and Accurate Cutting

- Clean and Sharp Edges

- Uniform Cuts and Consistent Quality

- Longevity and Visual Appeal

This modern cutting method revolutionizes the production of plastic car badges, offering precision, versatility, and the ability to bring custom designs to life with exceptional accuracy.

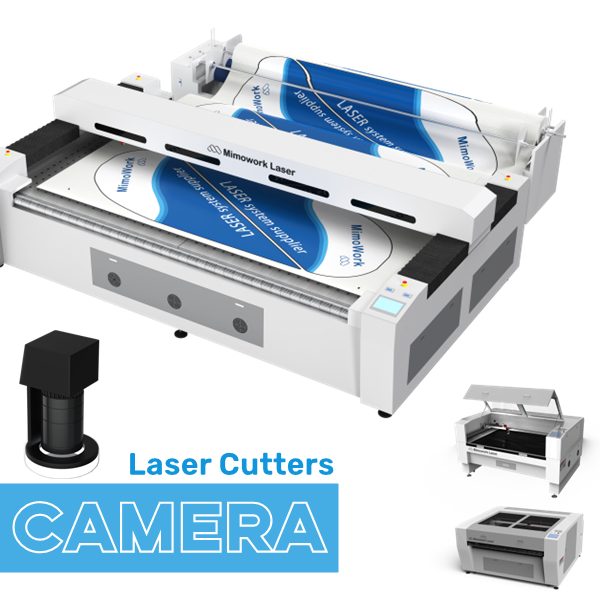

Recommended Laser Cutting Machine for Custom Car Emblems

Benefits of Laser Cutting Car Badges (Than Traditional Knife Cutting)

Laser-cutting car badges provide unique advantages over traditional knife-cutting methods, offering superior quality and efficiency. Here are some specific advantages of laser cutting in comparison:

Precision and Intricate Detail:

Laser cutting offers unmatched precision when creating intricate details on car badges. The focused laser beam can achieve fine cuts and intricate patterns with exceptional accuracy, ensuring that every detail is captured flawlessly. Traditional knife cutting methods may struggle to achieve the same level of precision and intricacy.

Clean and Smooth Edges:

Laser cutting produces clean and smooth edges on car badges without any burrs or roughness. The laser beam melts or vaporizes the material with precision, resulting in crisp edges and a professional finish. In contrast, traditional knife cutting may lead to rough or uneven edges that require additional finishing and polishing.

Consistency and Reproducibility:

Laser cutting ensures consistency and reproducibility in car badge production. The precise nature of the laser beam guarantees uniform cuts across multiple badges, maintaining consistent quality and design. In contrast, traditional knife cutting may lead to variations in cuts, compromising the consistency of the final product.

Safety and Cleanliness:

Laser cutting is a non-contact process, reducing the risk of accidents or injuries associated with traditional knife cutting. The laser beam operates without physical contact, ensuring operator safety and minimizing the risk of cuts or accidents during production. Additionally, laser cutting produces minimal dust or debris, contributing to a cleaner and safer working environment.

In summary

laser cutting car badges provides unique advantages such as precision, clean edges, material versatility, customization options, efficiency, consistency, safety, and cleanliness. These advantages make laser cutting the preferred method for creating high-quality, personalized, and visually appealing car badges with intricate detailing and superior craftsmanship.