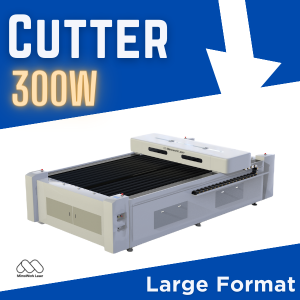

1325 CO2 Laser Cutting Machine

Advantages of 1325 CO2 Laser Cutting Machine

Revolutionizing Productivity with a Quantum Leap

◉ Sturdy construction: The machine has a reinforced bed made from 100mm square tubes and undergoes vibration aging and natural aging treatment for durability

◉ Precise transmission system: The machine's transmission system consists of an X-axis precision screw module, a Y-axis unilateral ball screw, and a servo motor drive for accurate and reliable operation.

◉ Constant Optical Path Design: The machine features a constant optical path design with five mirrors, including third and fourth mirrors that move with the laser head to maintain the optimal output optical path length.

◉ CCD camera system: The machine is equipped with a CCD camera system that enables edge finding and expands the range of applications

◉ High production speed: The machine has a maximum cutting speed of 36,000mm/min and a maximum engraving speed of 60,000mm/min, allowing for faster production.

Details of 1325 CO2 Laser Cutting Machine

Technical Data

| Working Area (W * L) | 1300mm * 2500mm (51” * 98.4”) |

| Software | Offline Software |

| Laser Power | 150W/300W/450W |

| Laser Source | CO2 Glass Laser Tube |

| Mechanical Control System | Ball Screw & Servo Motor Drive |

| Working Table | Knife Blade or Honeycomb Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~3000mm/s2 |

| Position Accuracy | ≤±0.05mm |

| Machine Size | 3800 * 1960 * 1210mm |

| Operating Voltage | AC110-220V±10%,50-60HZ |

| Cooling Mode | Water Cooling and Protection System |

| Working Environment | Temperature:0—45℃ Humidity:5%—95% |

Video Demonstration of Thick Acrylic Laser Cutting

Extra Thick, Extra Wide

A clear and smooth edge without chipping

✔ Burr-free cutting: Laser cutting machines utilize a powerful laser beam to cut through a variety of materials with ease. This results in a clean, burr-free cutting edge that requires no additional processing or finishing.

✔ No shavings: Unlike traditional cutting methods, laser cutting machines produce no shavings or debris. This makes cleaning up after processing quick and easy.

✔ Flexibility: With no limitations on shape, size, or pattern, laser cutting, and engraving machines allow for flexible customization of a wide range of materials.

✔ Single processing: Laser cutting and engraving machines are capable of performing both cutting and engraving in a single process. This not only saves time but also ensures that the end product meets the most exacting standards.

Metal Cutting & Engraving

High speed & high quality with force-free and top precision

✔ Stress-free and contactless cutting avoid metal fracture and breakage with proper power

✔ Multi-axis flexible cutting and engraving in multi-direction results to diverse shapes and complex patterns

✔ Smooth and burr-free surface and edge eliminate secondary finishing, meaning short workflow with quick response