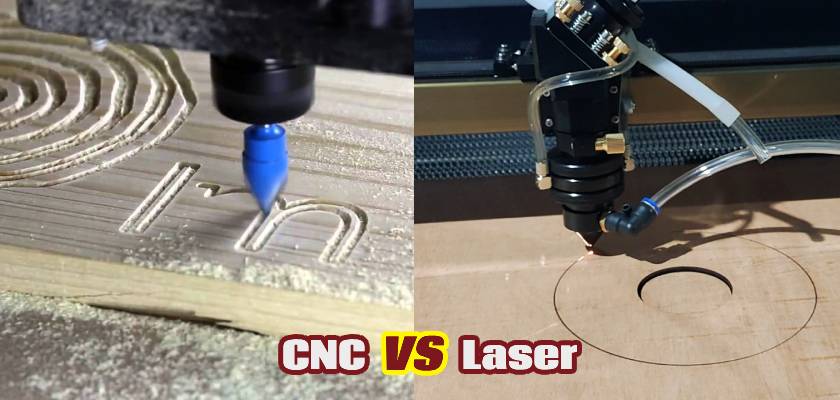

What is the difference between cnc router and laser cutter? For cutting and engraving wood, woodworking enthusiasts and professionals alike often face the dilemma of selecting the right tool for their projects. Two popular options are CNC (Computer Numerical Control) routers and CO2 laser machines, each with its unique set of advantages and applications. In this article, we'll explore the differences between these tools and help you make an informed choice for your woodworking needs.

Pick Up Quickly >>

Key Points:

CNC Routers

Advantages:

• Achieve precise cutting depths with Z-axis control.

• Effective for handling gradual curves and intricate carving.

• Suitable for 3D woodworking and detailed designs.

Disadvantages:

• Limited precision in handling sharp angles due to cutting bit radius.

• Requires secure material anchoring, which can cause tension in some cases.

Laser Cutters

Advantages:

• Non-contact cutting with intense heat.

• Exceptional precision for intricate cuts and sharp edges.

• Seals edges to minimize wood expansion and contraction.

Disadvantages:

• May result in wood discoloration, but preventable with proper measures.

• Less effective for gradual curves and rounded edges.

Step by Step Breakdown>>

All-round Interpretation:

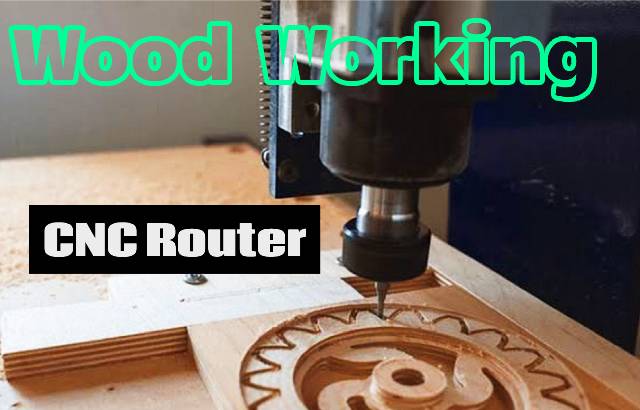

1. What is CNC Router for wood?

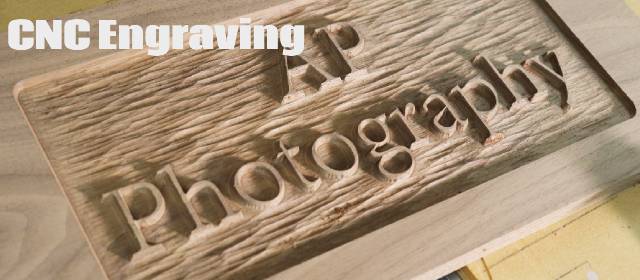

A CNC (Computer Numerical Control) router is a versatile woodworking tool that has transformed the world of craftsmanship and precision woodworking. Controlled by computer programs, CNC routers operate with exceptional precision and can produce intricate designs and cuts in wood. They utilize a spinning bit to remove material from a workpiece, making them suitable for various tasks, from detailed carvings and 3D woodworking to precise edge profiles, and even engraving. In this article, we will explore the capabilities and advantages of CNC routers in the context of woodwork, helping you understand how this technology has become an indispensable tool for woodworking enthusiasts and professionals.

2. What is Laser Cutter for wood?

Laser cutters, powered by high-energy light beams, have emerged as a revolutionary tool in the field of woodworking. These machines employ the precision of lasers to make intricate and highly accurate cuts, as well as engravings, in various materials, including wood. With the ability to create remarkably fine and sharp edges, laser cutters have gained popularity for their exceptional precision and intricate cutting capabilities in woodworking, whether it's for crafting, shaping, or engraving wood surfaces. In this article, we will delve into the world of CO2 laser cutters and explore their applications in woodworking, helping you grasp how this cutting-edge technology has redefined the boundaries of creativity and craftsmanship.

3. Difference: CNC VS. Laser Cutter

◼ Dive Deep into the Working Principle - How it works?

CNC Routers

A CNC router operates on a subtractive manufacturing principle. It's essentially a computer-controlled cutting machine that uses a spinning cutting tool, such as a router bit or end mill, to remove material from a workpiece. The router bit rotates at high speeds and is brought into contact with the material, which could be wood, plastic, or other substrates. As the bit makes contact, it gradually carves away the material, creating shapes, patterns, and designs.

The router's movements are precisely controlled in three dimensions (X, Y, and Z) by a computer program. This allows for precise control over the tool's position and depth. CNC routers excel at cutting, shaping, carving, and hollowing out material. They are highly suitable for tasks that require intricate, 3D, or detailed work, and they can be used for engraving by carefully controlling the depth and speed of the cutter.

Lase Cutters

Laser cutters work on a different principle known as subtractive photonic manufacturing. Instead of physical contact with the material, they use a high-energy laser beam to melt, vaporize, or burn away material from the workpiece. Laser cutters are often employed with a variety of materials, including wood, and can cut with precision. They also have engraving capabilities, creating intricate designs by varying the intensity and duration of the laser beam.

The laser cutter's computer-controlled system directs the laser beam to follow specific paths, creating intricate cuts and engravings. The key distinction here is that it is a non-contact method. The laser is incredibly precise and can create exceptionally fine details and sharp edges. It's especially effective for cutting and engraving wood, plastics, and other materials where precision and minimal material removal are required.

◼ If You Are into Cutting Wood:

CNC Routers

CNC routers are woodworking workhorses celebrated for their ability to seamlessly merge cutting ability with depth control. These machines are versatile, making them ideal for creating intricate designs, carving, and shaping wood. What sets them apart is their precision in achieving varying depths. With the Z-axis control, you have the power to finely adjust the depth of the cut. Whether it's detailed carvings, 3D woodworking, or producing complex edge profiles, CNC routers offer an array of possibilities. The cutting depth is essentially determined by the length of the cutting tool and the Z-axis's capabilities.

Lase Cutters

Laser cutters, while prized for their cutting precision, operate differently when it comes to depth. They excel in creating precise, shallow cuts and surface-level engraving, emphasizing finesse over depth. These machines are masters at producing intricate patterns, fine details, and sharp edges. While they can cut through wood, the primary focus is on the surface's quality rather than extensive material removal. Laser cutters are the champions of precision, crafting intricate designs on wood surfaces. The depth control, however, is limited compared to CNC routers, typically matching the thickness of the material they are working with.

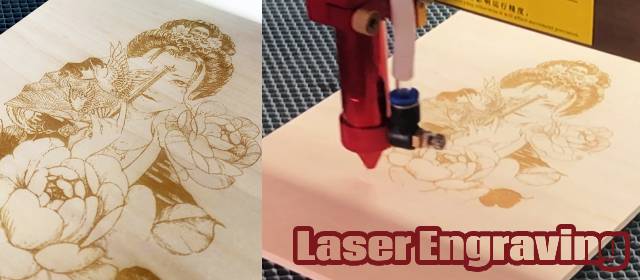

◼ If You Are Working on Engraving Wood:

Laser engraving wood is indeed superior for creating detailed engravings, especially when it comes to raster engraving, which involves shading or varying engraving depth to produce intricate patterns or images. The precision and non-contact nature of lasers make them perfect for achieving fine, detailed designs on various materials, including wood.

On the other hand, CNC routers are more suited for tasks that require intricate carving, shaping, and 3D woodworking but may not excel in producing the same level of detail in engravings as laser cutters. CNC routers are valuable for creating textured surfaces and complex edge profiles, making them versatile tools in woodworking.

Some Suggests:

Laser cutters are indeed superior for creating detailed engravings, especially when it comes to raster engraving, which involves shading or varying engraving depth to produce intricate patterns or images. The precision and non-contact nature of lasers makes them perfect for achieving fine, detailed designs on various materials, including wood.

◼ Consider the Efficiency and Speed for woodworking

When choosing between CNC routers and laser cutters for your woodworking project, understanding their cutting and engraving speeds is crucial. CNC routers operate by physically touching the material, which introduces some friction and may result in longer cutting times. In certain cases, multiple passes might be needed to complete the cut. In contrast, laser cutters are renowned for their speed and efficiency. They can swiftly traverse through materials, often completing tasks in a single pass.

For instance, cutting a 6mm MDF, the cnc router can cut through at a speed of 25mm per second, but the laser is faster, it can achieve the cutting work at 50mm per second for 300W laser. However, it's vital to note that as the material thickness increases, the speed and efficiency of laser cutting may decrease. For pretty thick wood, the cnc router is stronger to handle. But if speed and intricate detail are your primary needs, a laser cutter may be your preferred choice. Detailed information to inquire us>>

IF You have special requirements for custom wood design,

going for advice with a laser expert!

◼ Operation is easy or not?

When choosing between CNC routers and laser cutters for your woodworking project, understanding their cutting and engraving speeds is crucial. CNC routers operate by physically touching the material, which introduces some friction and may result in longer cutting times. In certain cases, multiple passes might be needed to complete the cut. In contrast, laser cutters are renowned for their speed and efficiency. They can swiftly traverse through materials, often completing tasks in a single pass.

In stark contrast, CNC machines entail a more complex learning curve. To master them, you must delve into the intricacies, which include comprehending the diverse router bits and their specific uses, alongside adjusting a range of parameters for optimal outcomes. If you're considering a CNC machine, expect a substantial learning curve, requiring a significant investment of time to grasp the tool and its intricate details.

◼ Which one is environmentally friendly?

• Noise

CNC Router:

CNC routers typically produce more noise compared to laser cutters. The noise level can vary depending on the type of router, cutting tool, and material being processed. It's generally advisable to use hearing protection when operating a CNC router, especially for extended periods.

Laser Cutter:

Laser cutters are relatively quieter in operation. While they do generate noise, it's generally at a lower decibel level than CNC routers. However, it's important to note that exhaust fans and air filtration systems, which are often used with laser cutters to remove fumes, can contribute to the overall noise level.

• Safety

CNC Router:

CNC routers are considered safer in terms of reducing the risk of inhaling fumes or dust produced during the cutting process. However, safety measures should still be in place, such as dust collection systems and proper ventilation, to minimize health risks associated with wood dust.

Laser Cutter:

Laser cutters can pose a safety concern due to the potential release of fumes and particulate matter when cutting or engraving wood. Materials like MDF and plywood can produce harmful emissions, and proper ventilation and exhaust systems are essential to maintain a safe working environment. Laser safety guidelines must be strictly followed to protect against laser radiation.

4. How to Choose CNC or Laser?

Consider Your Project Requirements:

For intricate carvings, 3D woodworking, and shaping tasks, CNC routers are a solid choice.

If precision, fine detailing, and intricate engraving are your priorities, opt for a laser cutter.

Speed and Efficiency:

CNC routers excel in material removal and shaping tasks, making them faster for these operations.

Laser cutters are faster and more efficient when it comes to precision cutting and intricate tasks.

Noise and Safety:

CNC routers are noisier during operation, so consider noise tolerance and use hearing protection.

Laser cutters are quieter but require strict safety measures due to potential fumes and laser radiation.

Learning Curve:

CNC routers have a steeper learning curve, requiring a deeper understanding of tooling and parameters.

Laser cutters offer a quicker learning curve for those looking for a 'plug-and-play' experience.

Material Removal vs. Detailing:

CNC routers are better for substantial material removal and creating textured surfaces.

Laser cutters are ideal for precision and fine detailing on the material's surface.

Material Thickness:

CNC routers can handle thicker materials better due to their deep-cutting ability.

Laser cutters are more suitable for thinner materials with a focus on surface quality.

Having any problems about cnc vs laser so far? Why not ask us for answers!

If you are interested in wood laser cutter

Check out the related machine >>

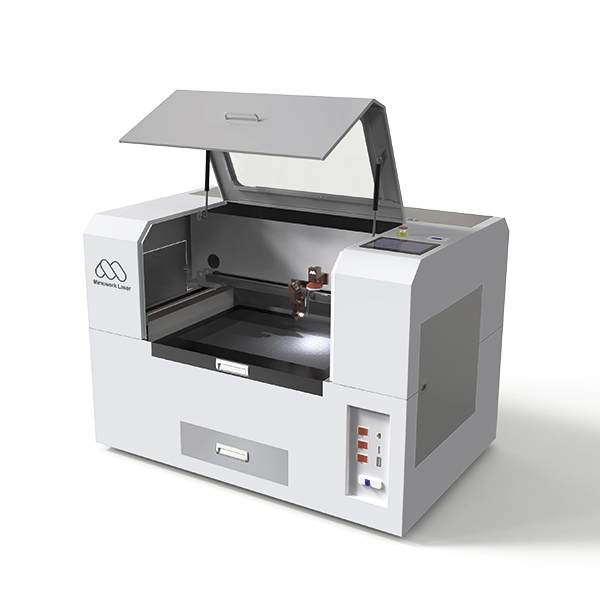

Working Table Size: 600mm * 400mm (23.6” * 15.7”)

Laser Power Options: 65W

Overview of Desktop Laser Cutter 60

The Flatbed Laser Cutter 60 is a desktop model. Its compact design minimizes the space requirements of your room. You can conveniently place it on a table for use, making it an excellent entry-level option for startups dealing with small custom products.

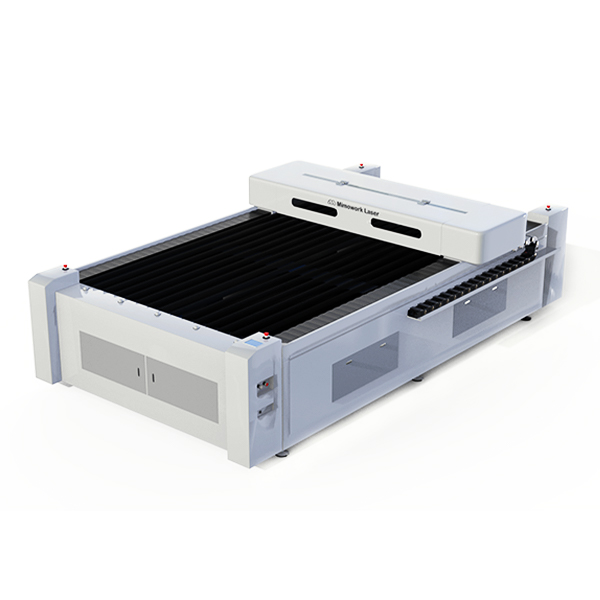

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 130

The Flatbed Laser Cutter 130 is the most popular choice for wood cutting. Its front-to-back through-type work table design enables you to cut wooden boards longer than the working area. Moreover, it offers versatility by equipping with laser tubes of any power rating to meet the needs for cutting wood with different thicknesses.

Working Table Size: 1300mm * 2500mm (51.2” * 98.4”)

Laser Power Options: 150W/300W/500W

Overview of Flatbed Laser Cutter 130L

The Flatbed Laser Cutter 130L is a large-format machine. It is suitable for cutting large wooden boards, such as the commonly found 4ft x 8ft boards in the market. It primarily caters to larger products, making it a favored choice in industries like advertising and furniture.

Want to start your own Laser Cutting/ Laser Engraving Business?

▶Sidenote: Besides wood, materials like plywood and MDF panels are also commonly used in the industry.

Post time: Oct-18-2023