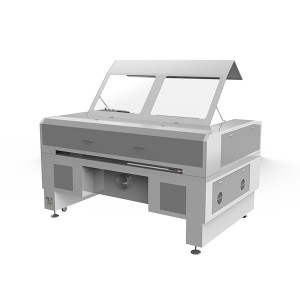

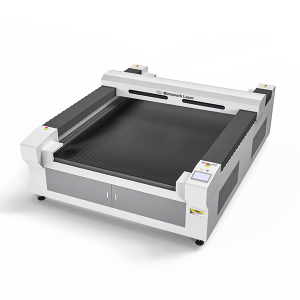

CO2 Laser Engraving Machine for Wood (Plywood, MDF)

▶ Laser Engraver for Wood (Woodworking Laser Engraver)

Technical Data

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Software |

Offline Software |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

2050mm * 1650mm * 1270mm (80.7'' * 64.9'' * 50.0'') |

|

Weight |

620kg |

Optional Upgrade: CO2 RF Metal Laser Tube Showcase

Multifunction in Wood Laser Engraver

Two-way Penetration Design

Stable and Safe Structure

◾ Signal Light

Signal light can indicate the working situation and functions exerting of laser machine, helps you to do the right judgment and operation.

◾ Emergency Button

Happen to some sudden and unexpected condition, the emergency button will be your safety guarantee by stopping the machine at once.

◾ Safe Circuit

Smooth operation makes a requirement for the function-well circuit, whose safety is the premise of safety production.

◾ CE Certification

Owning the legal right of marketing and distributing, MimoWork Laser Machine has been proud of the solid and reliable quality.

◾ Adjustable Air Assist

Air assist can blow the debris and chippings from the surface of engraved wood, and give a degree of assurance for wood burn prevention. Compressed air from the air pump is delivered into the carved lines through the nozzle, clearing the extra heat gathered on the depth. If you want to achieve burning and darkness vision, adjust the pressure and size of airflow for your desire. Any questions to consult us if you are confused about that.

Upgrade with

CCD Camera for your Printed Wood

CCD Camera can recognize and locate the printed pattern on the wood board to assist the laser with accurate cutting. Wood signage, plaques, artwork and wood photo made of printed wood can be easily processed.

Production Process

Step 1 .

>> Directly print your pattern on the wood board

Step 3 .

>> Collect your finished pieces

(Wood Laser Engraver and Cutter Boosts your Production)

Other upgrade options for you to choose

Servo Motors

DC Brushless Motors

Mixed Laser Head

Auto Focus

Ball & Screw

Samples of Wood Laser Engraving

What Kind of Wood Project Can I Work On With My CO2 Laser Engraver?

• Custom Signage

• Wooden Trays, Coasters, and Placemats

• Home Décor (Wall Art, Clocks, Lampshades)

• Architectural Models/ Prototypes

Videos Display

Laser Engraved Wood Photo

✔ Flexible design customized and cut

✔ Clean and intricate engraving patterns

✔ Three-dimensional effect with adjustable power

Typical Materials

— laser cutting and engraving wood (MDF)

Bamboo, Balsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Laminated Wood, MDF, Multiplex, Natural Wood, Oak, Plywood, Solid Wood, Timber, Teak, Veneers, Walnut…

Vector Laser Engraving Wood

Vector laser engraving on wood refers to using a laser cutter to etch or engrave designs, patterns, or text onto wood surfaces. Unlike raster engraving, which involves burning pixels to create the desired image, vector engraving uses paths defined by mathematical equations to produce precise and clean lines. This method allows for sharper and more detailed engravings on wood, as the laser follows the vector paths to create the design.

Any Questions About How to Laser Engrave Wood?

Related Wood Laser Machine

Wood and Acrylic Laser Cutter

• Suitable for large format solid materials

• Cutting multi-thickness with optional power of laser tube

Wood and Acrylic Laser Engraver

• Light and compact design

• Easy to operate for beginners

# What to note before laser cutting & engraving wood?

It's important to note that different types of wood have varying densities and moisture content, which can affect the laser-cutting process. Some woods may require adjustments to the laser cutter settings to achieve the best results. Additionally, when laser-cutting wood, proper ventilation and exhaust systems are essential to remove the smoke and fumes generated during the process.

# How thick of wood can a laser cutter cut?

With a CO2 laser cutter, the thickness of wood that can be effectively cut depends on the power of the laser and the type of wood being used. It's important to keep in mind that the cutting thickness may vary depending on the specific CO2 laser cutter and the power output. Some high-powered CO2 laser cutters may be able to cut thicker wood materials, but it's essential to refer to the specifications of the particular laser cutter being used for precise cutting capabilities. Additionally, thicker wood materials may require slower cutting speeds and multiple passes to achieve clean and precise cuts.

# Can a laser machine cut wood of all types?

Yes, a CO2 laser can cut and engrave wood of all types, including birch, maple, plywood, MDF, cherry, mahogany, alder, poplar, pine, and bamboo. Extremely dense or hard solid woods like oak or ebony require higher laser power to process. However, among all kinds of processed wood, and chipboard, due to the high impurity content, it is not recommended to use laser processing

# Is it possible for a laser wood cutter to harm the wood it's working on?

To safeguard the integrity of the wood around your cutting or etching project, it's crucial to ensure the settings are appropriately configured. For detailed guidance on the proper setup, consult the MimoWork Wood Laser Engraving Machine manual or explore the additional support resources available on our website.

Once you've dialed in the correct settings, you can rest assured that there is no risk of damaging the wood adjacent to your project's cut or etch lines. This is where the distinctive capability of CO2 laser machines shines through – their exceptional precision sets them apart from conventional tools like scroll saws and table saws.