Introduction

What is CO2 Laser Cutting?

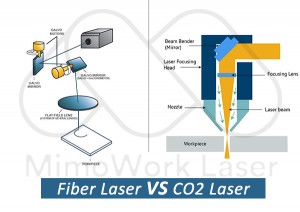

CO2 laser cutters use a high-pressure gas-filled tube with mirrors at each end. The mirrors reflect the light generated by the energized CO2 back and forth, amplifying the beam.

Once the light reaches the desired intensity, it is directed onto the chosen material for cutting or engraving.

The wavelength of CO2 lasers is typically 10.6μm, which is suitable for non-metal materials like Wood, Acrylic, and Glass.

What is Diode Laser Cutting?

Diode laser cutters use semiconductor diodes to produce a focused laser beam.

The light produced by the diodes is focused through a lens system, directing the beam onto the material for cutting or engraving.

The wavelength of diode lasers is typically around 450nm.

CO₂ Laser vs. Diode Laser: Acrylic Cutting Comparison

| Category | Diode Laser | CO₂ Laser |

| Wavelength | 450nm (Blue Light) | 10.6μm (Infrared) |

| Power Range | 10W–40W (Common Models) | 40W–150W+ (Industrial Models) |

| Max Thickness | 3–6mm | 8–25mm |

| Cutting Speed | Slow (Requires Multiple Passes) | Fast (Single-Pass Cutting) |

| Material Suitability | Limited to Dark/Opaque Acrylic (Black Works Best) | All Colors (Transparent, Colored, Cast/Extruded) |

| Edge Quality | May Require Post-Processing (Charring/Melting Risk) | Smooth, Polished Edges (No Post-Processing Needed) |

| Equipment Cost | Low | High |

| Maintenance | Low (No Gas/Complex Optics) | High (Mirror Alignment, Gas Refills, Regular Cleaning) |

| Energy Consumption | 50–100W | 500–2,000W |

| Portability | Compact, Lightweight (Ideal for Small Workshops) | Large, Stationary (Requires Dedicated Space) |

| Safety Requirements | An additional smoking hood needs to be installed | Optional closed cutting is available to prevent gas leakage |

|

Best For |

Hobbyists, Thin Dark Acrylic, DIY Projects |

Professional Production, Thick/Transparent Acrylic, High-Volume Jobs |

Related Videos

Thick Acrylic Laser Cutting

Want to cut acrylic with a laser cutter? This video demonstrates the process using a high-power laser cutter.

For thick acrylic, normal cutting methods may fall short, but a CO₂ laser cutting machine is up to the task.

It delivers clean cuts without needing post-polish, cuts flexible shapes without molds, and boosts acrylic production efficiency.

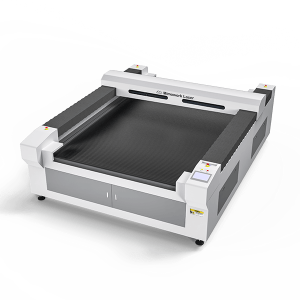

Recommend Machines

Working Area (W *L): 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power: 100W/150W/300W

Working Area (W *L): 1300mm * 2500mm (51” * 98.4”)

Laser Power: 150W/300W/450W

FAQs

Compared to diode lasers, CO2 lasers offer notable advantages.

They have quicker cutting speeds, can handle thicker materials, and are capable of cutting clear acrylic and glass, thus broadening creative possibilities.

CO₂ lasers offer a good balance for cutting and engraving on various materials.

Diode lasers work better with thinner materials and at lower speeds.

Post time: Apr-30-2025