3D Laser Engraving in Glass & Crystal

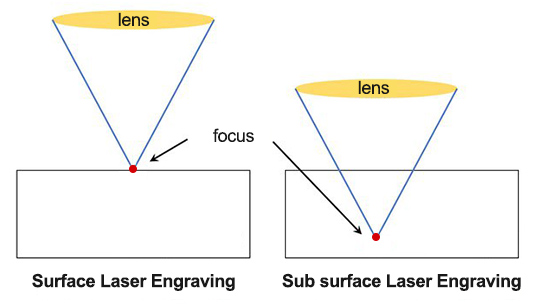

When it comes to laser engraving, you may already be quite familiar with the technology. Through the process of photoelectric conversion in the laser source, the energized laser beam removes a thin layer of surface material, creating specific depths that result in a visual 3D effect with color contrast and a tactile sense of relief. However, this is typically classified as surface laser engraving and is fundamentally different from true 3D laser engraving. In this article, we will take photo engraving as an example to explain what 3D laser engraving (also known as 3D laser etching) is and how it works.

Table of Contents

What is 3D laser engraving

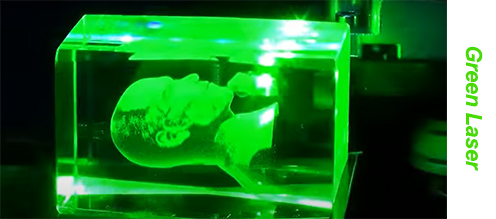

Like the pictures shown above, we can find them in the store as gifts, decorations, trophies, and souvenirs. The photo seems floating inside the block and presents in a 3D model. You can see it in different appearances at any angle. That's why we call it 3D laser engraving, subsurface laser engraving (SSLE), or 3D crystal engraving. There is another interesting name for "bubblegram". It vividly describes the tiny points of fracture made by laser impact like bubbles. Millions of tiny hollow bubbles constitute the three-dimensional image design.

How does 3D Crystal Engraving Work

Sounds amazing and magic. That's exactly a precise and unmistakable laser operation. Green laser excited by the diode is the optimal laser beam to pass through the material surface and react inside the crystal and glass. Meanwhile, every point size and position need to be accurately calculated and precisely transmitted to the laser beam from 3d laser engraving software. It is likely to be 3D printing to present a 3D model, but it occurs inside the materials and has no impact on the external material.

Some photos as a memory carrier are usually engraved inside the crystal and glass cube. The 3d crystal laser engraving machine, although for the 2d image, it can transform it into a 3d model to provide instruction for the laser beam.

Common applications of internal laser engraving

• 3d Crystal Portrait

• 3d Crystal Necklace

• Crystal Bottle Stopper Rectangle

• Crystal Key chain

• Toy, Gift, Desktop Decor

Adaptable materials

The green laser can be focused within the materials and positioned anywhere. That requires materials to be high optical clarity and high reflection. So crystal and some types of glass with an extremely clear optical grade are preferred.

- Crystal

- Glass

- Acrylic

Technology Support and Market Prospect

More fortunately, the green laser technology has been around for a long time and is equipped with mature technology support and reliable components supply. So the 3d subsurface laser engraving machine can provide manufacturers a super excellent opportunity to expand business. That is a flexible creation tool to realize the design of unique memorial gifts.

(3d photo crystal engraving with green laser)

The highlights of laser crystal photo

✦ Exquisite and crystal-clear laser engraved 3d photo crystals

✦ Any design can be customized to present a 3D rendering effect (including the 2d image)

✦ Permanent and impervious image to be reserved

✦ No heat-affected on the materials with the green laser

⇨ The article will be continuously updated…

Waiting for your coming and exploring the magic of 3d laser engraving in glass and crystal.

- how to make 3d grayscale images for 3d engraving?

- how to select the laser machine and others?

Any Questions about the 3d Laser Engraving in Crystal & Glass

⇨ Subsequent updating…

Thanks to the visitors' love and great demand for 3D subsurface laser engraving, MimoWork offers the two types of 3D laser engraver to meet laser engraving glass and crystal of different sizes and specifications.

3D Laser Engraver Recommendation

Suitable for: laser engraved crystal cube, glass block laser engraving

Features: compact size, portable, fully-enclosed and safe design

Suitable for: large size of glass floor, glass partition and other decor

Features: flexible laser transmission, high-efficiency laser engraving

Learn more Detailed Information about 3D Engraving Laser Machine

Who are we:

Mimowork is a results-oriented corporation bringing 20-year deep operational expertise to offer laser processing and production solutions to SMEs (small and medium-sized enterprises) in and around clothing, auto, ad space.

Our rich experience of laser solutions deeply rooted in the advertisement, automotive & aviation, fashion & apparel, digital printing, and filter cloth industry allows us to accelerate your business from strategy to day-to-day execution.

We believe that expertise with fast-changing, emerging technologies at the crossroads of manufacture, innovation, technology, and commerce are a differentiator. Please contact us: Linkedin Homepage and Facebook homepage or info@mimowork.com

FAQ

Yes. Unlike flat engraving, 3D laser engravers can automatically adjust the focal length, enabling engraving on uneven, curved, or spherical surfaces.

Most machines achieve ±0.01 mm accuracy, making them ideal for detailed engraving like portraits, fine jewelry, or high-precision industrial applications.

Yes. Laser engraving is a non-contact process with minimal waste, no inks or chemicals, and reduced tool wear compared to traditional engraving methods.

Regular cleaning of the optical lens, checking the cooling system, ensuring proper ventilation, and periodic calibration help maintain stable performance.

Learn More about the 3D Laser Engraving Machine ?

Last Updated: September 9, 2025

Post time: Apr-05-2022