5 Tips for Starting a Laser Engraving Business

Is Starting a Laser Engraving Business a Smart Investment?

Laser engraving business, with its versatile, in-demand services for precise personalization and branding, is a smart investment for many entrepreneurs. Success relies on understanding market demand, planning hidden costs, and picking the right tools. For small businesses or scaling hobbyists, strategic execution offers flexibility and strong profit potential.

Tip1. Prioritize Best-Selling Laser Engraving Products

The most sought-after items for laser engraving span personal, commercial, and industrial uses. Focusing on these can boost your business’s appeal:

Personalized Gifts

Customized jewelry (pendants, bracelets), wooden photo frames, leather wallets, and engraved glassware (wine glasses, mugs) are perennial favorites for birthdays, weddings, and holidays.

Industrial Parts

Metal components (tools, machinery parts), plastic casings, and electronic device panels require precise engraving for serial numbers, logos, or safety information.

Home Decor

Engraved wooden signs, ceramic tiles, and acrylic wall art add unique flair to living spaces, making them popular among homeowners and interior designers.

Pet Accessories

Custom pet tags (with names and contact info) and engraved pet memorials (wooden plaques) have seen rising demand as pet ownership grows.

These products benefit from high profit margins because customization adds significant value—customers are often willing to pay 2–3x the base price for personalized touches.

Tip2. What Do You Really Need to Start?

Launching a laser engraving business requires more than just a machine. Here’s the essential checklist:

• Core Equipment: A laser engraver (CO₂, fiber, or diode—depending on materials you’ll work with), a computer (to design and send files to the machine), and design software (e.g., Adobe Illustrator, CorelDRAW, or free tools like Inkscape).

• Workspace: A well-ventilated area (lasers produce fumes) with enough space for the machine, materials storage, and a workbench. If operating from home, check local zoning laws to ensure compliance.

• Materials: Stock up on popular substrates like wood, acrylic, leather, metal, and glass. Start with 2–3 materials to avoid overstocking.

• Permits & Licenses: Register your business (LLC, sole proprietorship, etc.), obtain a sales tax permit (if selling physical products), and check fire safety regulations for your workspace (due to laser heat).

• Marketing Tools: A simple website (to showcase work and take orders), social media accounts (Instagram, Facebook for visual portfolios), and business cards for local networking.

Tip3. How to Save Costs When Starting?

Startup costs can be optimized with these strategies, even for small-to-mid-sized operations:

Laser Engraver: Opt for entry-level CO₂ machines for materials like wood, acrylic, or glass first. You can also consider used machines to cut initial expenses.

Software & Computer: Use affordable or free design software trials, and repurpose an existing mid-range laptop instead of buying new.

Workspace Setup: Use basic shelving and workbenches you already have. For ventilation, open windows or use low-cost fans initially, and prioritize essential safety gear like goggles.

Materials & Supplies: Buy materials in small batches to test demand first, and source from local suppliers to save on shipping.

Legal & Marketing: Handle simple business registration yourself, and use free social media platforms for initial branding instead of costly website hosting at the start.

Start small to test the market, then scale up equipment and spending as your business grows.

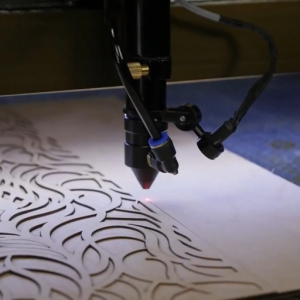

CO2 Laser Engraving Machine Working

How to Cut Startup Costs for Laser Busines?

Tip4. How to Boost Return on Investment?

Let me tell you straight: buying a laser machine and expecting it to print money while you kick back? That’s not how it works. But here’s the good news—with a little creativity and grit, you can build a laser cutting and engraving business that doesn’t just pay for the machine, but grows into something more. First things first, though: picking the right laser engraver matters a lot if you want to turn a profit.

We’ve seen it happen: some of our customers have paid off their entire machine in just three months. How? It’s all about mixing three things right: making top-notch products, treating customers like gold, and always pushing to grow. When you nail those, word gets around fast. Before you know it, orders start piling up—way quicker than you might expect.

Tip5. Key Points for Choosing a Laser Engraver

When you’re running a laser business, let’s be real—the machine is your biggest investment. It’s the heart of what you do, so getting one that’s both affordable and high-quality isn’t just smart—it’s what keeps your business thriving long-term.

We get it: every business is different. That's why you need to know about two main types of laser engravers: CO₂ laser engraving machines and fiber laser engraving machines. CO₂ laser engravers are great for non-metal materials like wood、acrylic、leather and glass.Whether it’s basic pattern engraving or intricate texture work, practical needs like How to Engrave Wood can be achieved with precise processing through these machines, which also handle cutting of these materials. Fiber laser engravers, on the other hand, excel at marking and engraving metal surfaces, such as stainless steel, aluminum, and brass. They’re also suitable for some plastic materials.

There’s a range of models for both types at different price points, so you can find something that fits your needs and budget. No matter which type or model you pick, you want pro-level quality. Good machines should be easy to use, and reliable support is essential—whether you’re just starting out or need help down the line.

8 Things to Check Before You Buy Laser Machines Overseas

Recommended Laser Engraver

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Max Speed |

1~400mm/s |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Working Area (W * L) | 70*70mm, 110*110mm, 175*175mm, 200*200mm |

| Marx Speed | 8000mm/s |

| Laser Power | 20W/30W/50W |

| Laser Source | Fiber Lasers |

|

Working Area (W*L) |

600mm * 400mm (23.6” * 15.7”) |

|

Max Speed |

1~400mm/s |

|

Laser Power |

60W |

|

Laser Source |

CO2 Glass Laser Tube |

FAQS

Not really. Most laser engravers come with user-friendly tutorials. Start with basic materials like wood, practice adjusting settings (power, speed), and you’ll master it soon. With patience and practice, even beginners can create great engravings.

Not usually. Regular upkeep (cleaning lenses, checking ventilation) is simple and low-cost. Major repairs are rare if you follow manufacturer guidelines, making long-term maintenance manageable.

Balancing quality and speed. New operators often struggle with perfecting settings for different materials, but practice and testing batches help. Also, attracting initial customers requires consistent marketing of your engraving capabilities.

Focus on niche products (e.g., custom pet tags, industrial part marking) and highlight quality. Use social media to showcase unique designs and fast turnaround times. Building a loyal customer base with consistent results and personalized service keeps you ahead in the market.

Learn More about the Laser Engraving Machine ?

Post time: Aug-18-2025