How to cut fabric perfectly straight with textile laser cutter

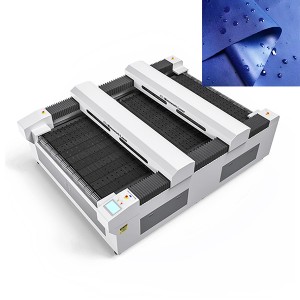

Laser cutter machine for fabric

Cutting fabric straight can be a challenging task, especially when dealing with large quantities of fabric or intricate designs. Traditional cutting methods such as scissors or rotary cutters can be time-consuming and may not result in a clean and precise cut. Laser cutting is a popular alternative method that provides an efficient and accurate way to cut fabric. In this article, we will cover the basic steps of how to use industrial fabric laser cutting machine and provide some tips and tricks to help you cut fabric perfectly straight and achieve the best results.

Step 1: Choose the Right Textile Laser Cutting Machine

Not all textile laser cutters are created equal, and choosing the right one is crucial to achieving a precise and clean cut. When selecting a textile laser cutter, consider the thickness of the fabric, the size of the cutting bed, and the power of the laser. A CO2 laser is the most commonly used type of laser for cutting fabric, with a power range of 40W to 150W depending on the thickness of the fabric. MimoWork also provide much high power like 300W and 500W for industrial fabric.

Step 2: Prepare the Fabric

Before laser cutting fabric, it is important to prepare the material properly. Start by washing and ironing the fabric to remove any wrinkles or creases. Then, apply a stabilizer to the back of the fabric to prevent it from moving during the cutting process. A self-adhesive stabilizer works well for this purpose, but you can also use a spray-on adhesive or a temporary fabric glue. Many of MimoWork’s industrial clients often process fabric in rolls. In such case, they only need put the fabric on the auto feeder and achieve continuously automatically fabric cutting.

Step 3: Create the Cutting Pattern

The next step is to create the cutting pattern for the fabric. This can be done using a vector-based design software such as Adobe Illustrator or CorelDRAW. The cutting pattern should be saved as a vector file, which can be uploaded to the laser cutting cloth machine for processing. The cutting pattern should also include any etching or engraving designs that are desired. MimoWork’s laser cutting cloth machine supports DXF, AI, PLT and many other design file formats.

Step 4: Laser Cut the Fabric

Once the laser cutter for textile is set up and the cutting pattern is designed, it is time to start the fabric laser cutting process. The fabric should be placed on the cutting bed of the machine, making sure it is level and flat. The laser cutter should then be turned on, and the cutting pattern should be uploaded to the machine. The laser cutter for textile will then follow the cutting pattern, cutting through the fabric with precision and accuracy.

For achieving the best results when laser cutting fabric, you shall also turn on the exhaust fan and air blowing system. Remember, choose focus mirror with shorter focus length is usually a good idea since the most of the fabric is pretty thin. These are all very important components of a good-quality textile laser cutting machine.

In conclusion

In conclusion, laser cutting fabric is an efficient and accurate way to cut fabric with precision and accuracy. By following the steps outlined in this article and using the tips and tricks provided, you can achieve the best results when using your industrial fabric laser cutting machine for your next project.

Recommended Laser cutter machine for fabric

Want to invest in Laser cutting on fabrics?

Post time: Mar-15-2023