How to Laser Cut Cordura Patch?

What is Cordura Patches

Cordura patches come in various shapes, with laser cut Cordura patches boasting custom designs/logos. Sewn on, they add strength and resist wear. Tougher to cut than regular woven patches due to Cordura’s durability—abrasion, tear, and scuff-resistant. Most laser cut police patches use Cordura, making laser cut Cordura patches a mark of toughness.

Laser Cut Cordura Patch

Operation Steps – Laser Cut Cordura Patches

To cut Cordura patch with a laser machine, you will need to follow these steps:

1. Prepare the design of the fabric patch in vector formats such as .ai or .dxf.

2. Import the design file into the MimoWork laser cutting software that controls the CO₂ laser cutting machine, with integrated CCD camera recognition capabilities.

3. Set the cutting parameters in the software, including laser speed, power, and the number of passes required for cutting Cordura materials. For Cordura patches with adhesive backing, higher power and an adjusted air-blowing system are necessary – camera systems can help detect material types for parameter suggestions.

4. Place the Cordura fabric piece on the laser cutting bed. CCD camera recognition systems will automatically identify the fabric's position and edges upon placement.

5. Camera recognition systems precisely locate the fabric and calibrate the laser focus and cutting position, ensuring alignment with your design.

6. Start the laser cutting process, with CCD camera recognition systems monitoring the cutting area in real-time to ensure accuracy throughout the operation.

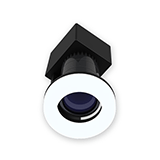

What is CCD Camera?

Whether you need a CCD camera on the laser machine depends on your specific requirements. A CCD camera can help you to precisely position the design on the fabric and ensure that it is cut correctly. However, it may not be necessary if you can accurately position the design using other methods. If you frequently cut complex or intricate designs, a CCD camera can be a valuable addition to your laser machine. A CCD camera is the key component of the camera recognition system. This integrated system combines the camera’s image - capturing capability with intelligent software to achieve automated, high - precision positioning and cutting control for Cordura patches

CCD Camera

What Benefits of Using CCD Camera?

If your Cordura Patch and Police Patch comes with pattern or other design elements, CCD camera is quite useful. can capture an image of the workpiece or the laser bed, which can then be analyzed by the software to determine the position, size, and shape of the material and the location of the desired cut.The camera recognition system, powered by the CCD camera, offers comprehensive benefits for Cordura patch cutting:

The camera recognition system can be used to perform a number of functions, including:

Automatic Material Detection

The camera can identify the type and color of the material being cut and adjust the laser settings accordingly

Automatic Registration

The camera can detect the position of previously cut features and align new cuts with them

Positioning

The camera can provide a real-time view of the material being cut, allowing the operator to accurately position the laser for precise cuts

Quality Control

The camera can monitor the cutting process and provide feedback to the operator or software to ensure that the cuts are being made correctly

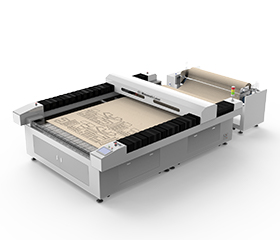

Recommended Fabric Laser Cutter

Overall, a camera recognition system can increase the accuracy and efficiency of laser cutting by providing real-time visual feedback and positioning information to the software and operator. To sum it up, it’s always a great choice to use CO2 laser machine to laser cut police patch and cordura patch.

FAQs

Yes, but with limits. You can position designs manually, but accuracy drops for complex patterns. Without it, aligning small logos or intricate shapes on Cordura is tricky. A CCD camera simplifies the process, especially for batch - cutting or detailed patches. So, while possible without, it’s far easier and more accurate with a CCD camera for professional - looking results.

It solves alignment and accuracy issues. Cordura’s texture can make manual positioning hard—CCD camera auto - registers designs, matches pre - cut marks, and monitors cuts in real - time. It also handles material variations (like adhesive - backed patches) by detecting fabric edges. In short, it eliminates guesswork, ensuring every Cordura patch cuts perfectly.

Yes, it’s versatile. Whether cutting plain Cordura patches, those with adhesive backing, or police patches with complex logos—CCD camera adapts. It reads fabric patterns, auto - adjusts for material differences, and ensures precise cuts. No matter the patch design or Cordura type, it helps deliver consistent, accurate results.

Want to Know More about Our Laser Cutting Machine for Your Cordura Patch?

Post time: May-08-2023