Making Swimsuits with Fabric Laser Cutting Machines Pros and Cons

laser cut swimsuit by fabric laser cutter

Swimsuits are a popular garment that require precision cutting and sewing to ensure a comfortable and secure fit. With the increasing availability of fabric laser cutting machines, some are considering using this technology to make swimsuits. In this article, we will explore the pros and cons of using laser fabric cutters to make swimsuits.

Pros

• Precision Cutting

One of the main advantages of using a fabric laser cutting machine to make swimsuits is the precision cutting it provides. The laser cutter can create accurate and complex designs with clean edges, making it easy to cut intricate shapes and patterns in swimsuit fabric.

• Time Efficiency

Using a laser fabric cutter can save time in the production process by automating the cutting process. The laser cutter can cut multiple layers of fabric at once, reducing the time required for cutting and improving overall productivity.

• Customization

Fabric laser cutting machines allow for customization of swimsuit designs. The machine can cut a variety of shapes and patterns, making it possible to create unique designs and custom fits for customers.

• Material Efficiency

Fabric laser cutting machines can also improve material efficiency by reducing fabric waste. The machine can be programmed to optimize fabric usage by minimizing the space between cuts, which can reduce the amount of scrap fabric generated during the cutting process.

Cons

• Training Requirements

Using laser cutting for fabrics requires specialized training to operate. The operator must have a good understanding of the machine's capabilities and limitations, as well as safety protocols to ensure the safety of the operator and others in the workspace.

• Material Compatibility

Not all fabrics are compatible with laser cutting machines. Certain fabrics, such as those with reflective surfaces or metallic threads, may not be suitable for laser cutting due to the risk of fire or damage to the machine.

• Sustainability

Using fabric laser cutting machines to make swimsuits raises concerns about sustainability. The machine requires electricity to operate, and the production process can generate waste in the form of fumes and smoke. Additionally, the use of synthetic fabrics commonly used in swimsuits raises concerns about microplastic pollution and the environmental impact of production and disposal.

• Equipment Cost

One of the major drawbacks of using Fabric laser cutter to make swimsuits is the cost of the equipment. Laser cutting machines can be expensive, and this cost may be prohibitive for small businesses or individuals.

In Conclusion

Using fabric laser cutting machines to make swimsuits has both pros and cons. While the precision cutting and time efficiency of the machine can improve productivity and customization options, the high cost of equipment, training requirements, material compatibility, and sustainability concerns must also be considered. Ultimately, the decision to use a laser fabric cutter for swimsuit production will depend on the specific needs and priorities of the business or individual.

Video Display | Glance for Laser Cutting Swimwear

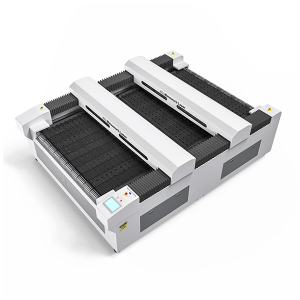

Recommended Fabric laser cutter

Any questions about the operation of Fabric Laser Cutter?

Post time: Apr-12-2023