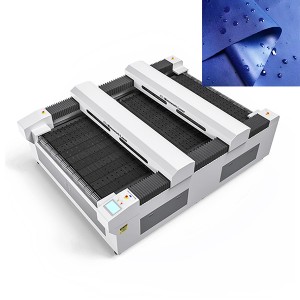

Flatbed Laser Cutter 160 with extension table

Quick Overview ⇨

What is Extension Table Laser Cutter?

▶ High Efficiency - collecting while cutting

▶ Versatile Use - cut pieces longer than working table

Advantages of Laser Cloth Cutting Machine

A Giant Leap in Productivity

◉ Innovative mechanical structure of extension table provides convenience for collecting finished pieces

◉ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Mark pen makes labor-saving process and efficient cutting & marking operations possible

◉ Upgraded cutting stability and safety - improved by adding the vacuum suction function

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Collecting Area (W * L) | 1600mm * 500mm (62.9'' * 19.7'') |

| Software | Offline Software |

| Laser Power | 100W / 150W / 300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive / Servo Motor Drive |

| Working Table | Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Multiple Laser Head option available

R&D for Fabric and Cloth Laser Cutting

Two Laser Heads - Option

Video Display - Laser Cutting Industrial Fabric

Laser Cutting Foam (Cushion, Toolbox Insert)

Laser Cutting Felt (Gasket, Mat, Gift)

✔ Standardized production of each piece of cloth cutting with the benefit of CNC control drive

✔ Smooth and lint-free edge through heat treatment

✔ High precision in cutting, marking, and perforating with fine laser beam

Engraving, marking, and cutting can be realized in single process

✔ High precision in cutting, marking, and perforating with fine laser beam

✔ Fewer material waste, no tool wear, better control of production costs

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Multiple Usage - One laser cutter can process variety of composite materials

Your popular and wise manufacturing direction

✔ Smooth and lint-free edge through heat treatment

✔ High quality brought by fine laser beam and contactless processing

✔ Greatly saving cost in materials waste

The secret of exquisite pattern cutting

✔ Realize unattended cutting process, reduce manual workload

✔ High-quality value-added laser treatments like engraving, perforating, marking, etc Mimowork adaptable laser ability, suitable to cut diverse materials

✔ Customized tables meet requirements for varieties of materials formats