Taslan Fabric: All the Information in 2024 [One & Done]

Have you ever felt a woven fabric with a bumpy texture that just seems to drape perfectly?

If you have, you might have stumbled upon Taslan!

Pronounced "tass-lon," this amazing fabric stands out for its unique look and incredible versatility. It's fun to explore, and once you get to know it, you’ll appreciate all the ways it can be used!

Table of Content:

1. What is Taslan Fabric?

The name "Taslan" actually comes from the Turkish word "tash," which means stone or pebble.

This makes perfect sense when you feel its bumpy, pebbly texture!

Taslan is crafted using a special weaving technique that creates those charming little irregular bumps, known as slubs, along the yarns.

These slubs not only contribute to its unique, pebbled look but also give the fabric an intriguing drape that makes it stand out.

2. Material Background of Taslan

Ready for a loooooooooooog history lesson?

While today’s Taslan is made with modern weaving techniques, its roots go back centuries to simpler times.

The first Taslan-like fabrics were handwoven by Turkish villagers in rural Anatolia, dating back to the 17th century.

Back then, weaving was done on basic looms using uneven, hand-spun yarns made from sheep's wool or goat hair.

Achieving perfectly even yarns was nearly impossible, so these fabrics naturally featured charming slubs and imperfections, giving them a unique character that we still appreciate today.

As those rustic yarns were woven, the slubs created little bumps across the surface of the fabric.

Instead of trying to smooth them out, weavers embraced this unique texture, making it a hallmark of the region's textiles.

Over time, as weaving techniques evolved, Taslan emerged as a specific method where weavers intentionally incorporated slubs into the yarns to achieve that signature pebbled look.

In the mid-20th century, Taslan weaving was modernized with larger looms, but the essence of the fabric remained unchanged.

The yarns still featured slubs—either naturally occurring or added during spinning—celebrated for their unique appearance.

This approach highlighted the imperfections and irregularities in the yarns as a beautiful part of the fabric's charm, rather than a flaw.

Today, Taslan is typically woven from yarns made of wool, alpaca, mohair, or cotton.

These fibers can naturally create slubs due to their irregularities, but often, slubs are intentionally added during the spinning process.

This technique, known as slubbing, involves overlapping bundles of fibers in an irregular way as they're spun, resulting in those delightful bumpy slubs along the yarn.

It’s this careful crafting that gives Taslan its unique texture and character!

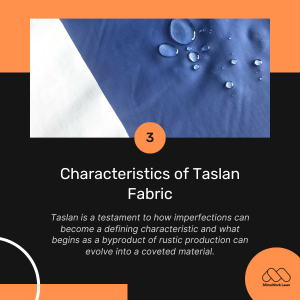

3. Characteristics of Taslan Fabric

In short:

Taslan has a pebbly, bumpy texture.

It has a very soft hand feel thanks to the slight puffiness from the slubs.

It also drapes beautifully and has a lot of movement.

It doesn't wrinkle or crush easily like other lightweight fabrics.

It is also very breathable due to its open, textured weave.

It is naturally wrinkle-resistant.

4. Applications of Taslan

Nylon Taslan comes in a vast array of colors, from understated neutrals to bold, vibrant hues.

Some popular options include silver, gold, copper, and pewter for a glamorous look.

You'll also find it in jewel tones like emerald, ruby, and amethyst if you want to inject some lavish color into your wardrobe.

Earthy shades like taupe, olive, and navy work well for a more minimalist aesthetic.

And for the boldest statements, opt for brights like fuchsia, cobalt, and lime green.

The iridescent quality of Taslan makes any hue truly pop.

Given its luxurious yet hardwearing construction, Taslan Nylon has uses well beyond just apparel.

Some popular applications include:

1. Evening Gowns, and Cocktail Dresses - The perfect choice for adding opulence to any special occasion look.

2. Blazers, Skirts, Trousers - Elevate work and business attire with a chic Taslan piece.

3. Home Decor Accents - Upholster pillows, curtains, or an ottoman for a glamorous touch.

4. Accessories - Lend some shine to a handbag, scarf, or jewelry with Taslan accents.

5. Wedding Party Attire - Make the bridal party or mother of the bride stand out.

5. How to Cut Taslan Fabric

Shears: Can work, but may require more passes which could risk fraying or distorting delicate designs.

Die/knife cutting: Will do for mass production of patterns. However, it's less suitable for one-off projects or intricate shapes.

CO2 Laser Cutting

For the highest quality cuts with no risk of fraying or distortion, CO2 laser cutting is the clear frontrunner method for Nylon Taslan.

Here's why:

1. Precision: Lasers cut with microscopic exactness, perfect for intricate patterns or templates with tight tolerances.

2. Clean edges: The laser cauterizes the fabric edge immediately, leaving no loose threads to unravel.

3. No contact: Taslan isn't compressed or stressed by physical contact, preserving its delicate metallic surface.

4. Any shape: Complex organic designs, logos, you name it - lasers can cut it without limitations.

5. Speed: Laser cutting is extremely fast, allowing high-volume production without compromising on quality.

6. No blade dulling: Lasers provide a virtually infinite blade life versus mechanical blades requiring replacement.

For those working with Taslan, a CO2 laser cutting system pays for itself by allowing an effortless, flawless cutting process every time.

It's truly the gold standard for maximizing both quality outputs and productivity.

Don't settle for less when cutting this exquisite fabric - laser is the way to go.

6. Care & Cleaning Tips for Taslan

Despite its delicate metallic appearance, Taslan Nylon Fabric is remarkably durable.

Here are some tips for caring for your Taslan items:

1. Dry cleaning is recommended for best results. Machine washing and drying can cause excess wear over time.

2. Store folded or on hangers away from direct sunlight or heat, which can cause fading.

3. For light spot cleaning between dry cleans, use a soft cloth and warm water. Avoid harsh chemicals.

4. Iron on the reverse side only using a press cloth and low heat setting.

5. Professional cleaning every 5-10 wears will help Taslan garments maintain their lustrous appearance.

7. FAQs about Taslan Fabric

A: No, thanks to its smooth twill weave structure, Taslan has a soft hand feel and is not at all itchy against the skin.

A: Like any fabric, Taslan is susceptible to fading with excessive exposure to sunlight. Proper care and storage away from direct light helps maintain its vivid colors.

A: Taslan has a medium weight and is neither overly warm nor cool. It strikes a nice balance that makes it suitable for year-round wear.

A: Taslan is surprisingly tough for a metallic fabric. With proper care, items made from Taslan can withstand regular everyday wear without pilling or snagging easily.

Recommended Machine for Laser Cutting Taslan Fabric

We Don't Settle for Mediocre Results, Neither Should You

Videos from Our Youtube Channel:

Laser Cutting Foam

Laser Cut Felt Santa

How Long will a CO2 Laser Cutter Last?

Find Laser Focal Length Under 2 Minutes

▶ About Us - MimoWork Laser

Elevate your Production with Our Highlights

Mimowork is a results-oriented laser manufacturer based in Shanghai and Dongguan, China, with 20 years of deep operational expertise. We specialize in producing laser systems and providing comprehensive processing and production solutions for small and medium-sized enterprises (SMEs) across various industries.

Our extensive experience in laser solutions covers both metal and non-metal material processing, with applications in sectors such as advertising, automotive and aviation, metalware, dye sublimation, and the fabric and textiles industry.

Instead of offering uncertain solutions from unqualified manufacturers, Mimowork controls every aspect of the production chain, ensuring that our products consistently deliver excellent performance.

MimoWork is dedicated to the creation and enhancement of laser production technologies. We have developed dozens of advanced laser technologies aimed at improving our clients' production capacity and efficiency.

With numerous patents in laser technology, we prioritize the quality and safety of our laser machine systems, ensuring consistent and reliable processing. Our laser machines are certified by CE and FDA, reflecting our commitment to high standards in quality and safety.

Get More Ideas from Our YouTube Channel

You Might be Interested in:

We Accelerate in the Fast Lane of Innovation

Post time: Feb-04-2024