About cutting foam, you may be familiar with hot wire(hot knife), water jet, and some traditional processing methods. But if you want to get higher precise and customized foam products like toolboxes, sound-absorbing lampshades, and foam interior decoration, the laser cutter must be the best tool. Laser cutting foam provides more convenience and flexible processing on a changeable production scale. What is a foam laser cutter? What is laser cutting foam? Why you should choose a laser cutter to cut foam?

Let's reveal the magic of LASER!

from

Laser Cut Foam Lab

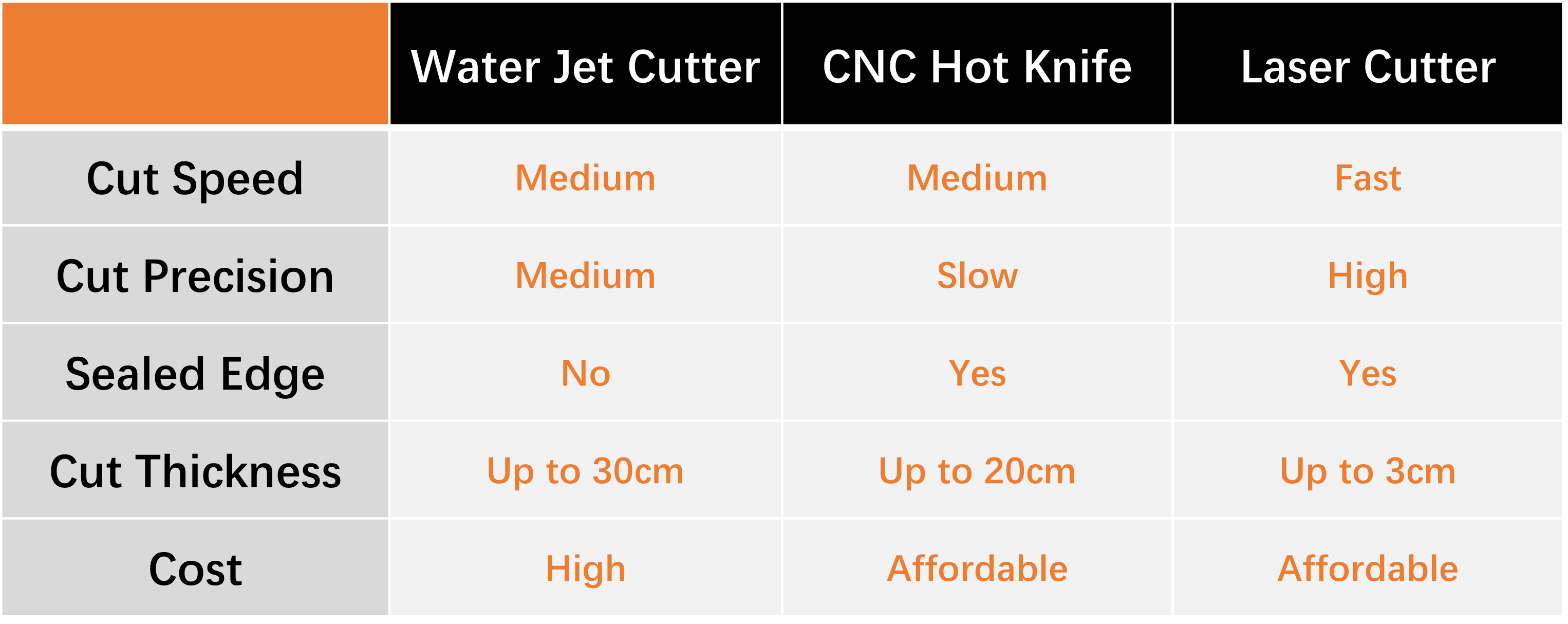

▶ How to Choose? Laser VS. Knife VS. Water Jet

Talk about the cutting quality

Focus on cutting speed and efficiency

In terms of pricing

▶ What Can You Get from Laser Cutting Foam?

CO2 laser cutting foam presents a multifaceted array of benefits and advantages. It stands out for its impeccable cutting quality, delivering high precision and clean edges, enabling the realization of intricate designs and fine details. The process is characterized by its high efficiency and automation, resulting in substantial time and labor savings, while achieving significantly higher yields compared to traditional methods. The inherent flexibility of laser cutting adds value through customized designs, shortening the workflow, and eliminating tool changeovers. Additionally, this method is environmentally friendly due to reduced material waste. With its ability to handle various foam types and applications, CO2 laser cutting emerges as a versatile and efficient solution for foam processing, meeting diverse industry needs.

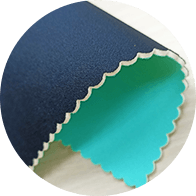

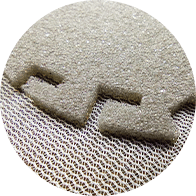

Crisp & Clean Edge

Flexible Multi-shapes Cutting

Vertical Cutting

✔ Excellent Precision

CO2 lasers offer exceptional precision, enabling intricate and detailed designs to be cut with high accuracy. This is particularly valuable for applications that require fine details.

✔ Fast Speed

Lasers are known for their swift cutting process, leading to faster production and shorter turnaround times for projects.

✔ Minimal Material Waste

The non-contact nature of laser cutting minimizes material waste, reducing costs and environmental impact.

✔ Clean Cuts

Laser cutting foam creates clean and sealed edges, preventing fraying or material distortion, resulting in a professional and polished appearance.

✔ Versatility

Foam laser cutter can be used with various foam types, such as polyurethane, polystyrene, foam core board, and more, making them suitable for a wide range of applications.

✔ Consistency

Laser cutting maintains consistency throughout the cutting process, ensuring that each piece is identical to the last.

▶ Versatility of Laser Cut Foam (Engrave)

What can you do with laser foam?

Laserable Foam Applications

Laserable Foam Applications

What type of foam can be laser cut?

What is Your Foam Type?

What is Your Application?

>> Check out the videos: Laser Cutting PU Foam

♡ We Used

Material: Memory Foam (PU foam)

Material Thickness: 10mm, 20mm

Laser Machine: Foam Laser Cutter 130

♡ You Can Make

Wide Application: Foam Core, Padding, Car Seat Cushion, Insulation, Acoustic Panel, Interior Decor, Crats, Toolbox and Insert, etc.

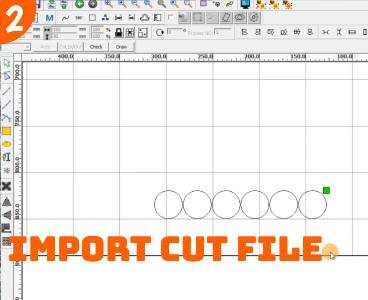

How to Laser Cut Foam?

Laser cutting foam is a seamless and automated process. Using the CNC system, your imported cutting file guides the laser head along the designated cutting path with precision. Simply place your foam on the worktable, import the cutting file, and let the laser take it from there.

Foam Preparation: keep the foam flat and intact on the table.

Laser Machine: choose laser power and machine size according to foam thickness and size.

▶

Design File: import the cutting file to the software.

Laser Setting: test to cut foam by setting different speeds and powers

▶

Start Laser Cutting: laser cutting foam is automatic and highly precise, creating constant high-quality foam products.

Cut Seat Cushion with Foam Laser Cutter

Any questions about how the lase cutting foam work, Contact Us!

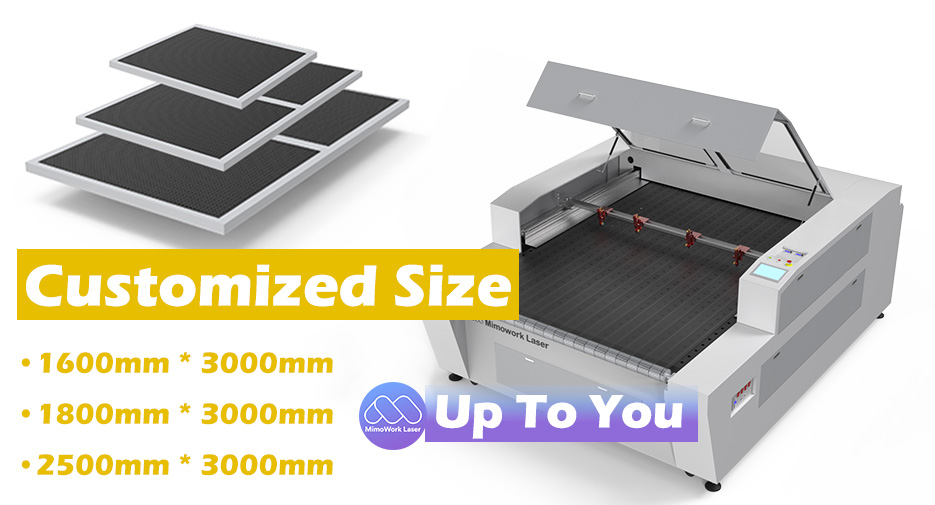

Popular Laser Foam Cutter Types

MimoWork Laser Series

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

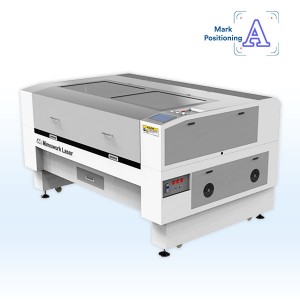

Overview of Flatbed Laser Cutter 130

For regular foam products like toolboxs, decorations, and crafts, the Flatbed Laser Cutter 130 is the most popular choice for foam cutting and engraving. The size and power satisfy most requirements, and the price is affordable. Pass through design, upgraded camera system, optional working table, and more machine configurations you can choose.

Working Table Size: 1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 160

The Flatbed Laser Cutter 160 is a large-format machine. With the auto feeder and conveyor table, you can accomplish auto-processing roll materials. 1600mm *1000mm of working area is suitable for most yoga mat, marine mat, seat cushion, industrial gasket and more. Multiple laser heads are optional to enhance productivity.

Send Your Requirements to Us, We will Offer A Professional Laser Solution

Start A Laser Consultant Now!

> What information you need to provide?

> Our contact information

FAQ: Laser Cutting Foam

▶ What is the best laser to cut foam?

▶ How thick can laser cut foam?

▶ Can you laser cut eva foam?

▶ Can laser cutter engrave foam?

▶ Some tips when you are laser cutting foam

Material Fixation: Use tape, magnet, or vacuum table to keep your foam flat on the working table.

Ventilation: Proper ventilation is crucial to remove smoke and fumes generated during cutting.

Focusing: Ensure that the laser beam is properly focused.

Testing and Prototyping: Always conduct test cuts on the same foam material to fine-tune your settings before starting the actual project.

Any questions about that?

Consult a laser expert is the best choice!

# How much does a co2 laser cutter cost?

# Is safe for laser cutting foam?

# How to find the right focal length for laser cutting foam?

# How to do nesting for your laser cutting foam?

• Import the File

• Click AutoNest

• Start Optimizing the Layout

• More Functions like co-linear

• Save the File

# What else material can laser cut?

Material Features: Foam

Dive Deeper ▷

You may be interested in

Video Inspiration

What is Ultra Long Laser Cutting Machine?

Laser Cutting & Engraving Alcantara Fabric

Laser Cutting & Ink-Jet Makring on Fabric

Any confusion or questions for the foam laser cutter, just inquire us at any time

Post time: Oct-25-2023