Wood For Laser Cutting: Detailed Information about Wood

Related Video & Related Links

How to Cut Thick Plywood

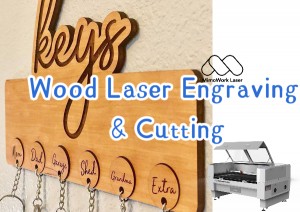

Laser cutting is a popular and precise method for shaping wood in various applications, from crafting intricate designs to producing functional components.

The choice of wood significantly impacts the quality and outcome of the laser cutting process.

Types of Wood Suitable for Laser Cutting

1. Softwoods

▶ Cedar

Color & Grain : Cedar is renowned for its light reddish hue. It has a straight grain pattern with some irregular knots.

Carving & Cutting Characteristics : Carving on cedar produces deep dark shades. Its fragrant aroma and natural decay - resistance make it an ideal choice for craftsmen's favorite craft materials.

▶ Balsa

Color & Grain : Balsa has a light yellowish - beige color and straight grain, making it the softest natural wood for carving.

Carving & Cutting Characteristics : Balsa is the lightest wood, with a density of 7 - 9lb/ft³. This makes it an ideal choice for applications where lightweight materials are crucial, such as model building. It is also used for insulation, floats, and other applications that require a lightweight yet relatively strong wood. It is also inexpensive, soft, with a fine and uniform texture, thus producing excellent carving results.

▶ Pine

Color & Grain : Cedar is renowned for its light reddish hue. It has a straight grain pattern with some irregular knots.

Carving & Cutting Characteristics : Carving on cedar produces deep dark shades. Its fragrant aroma and natural decay - resistance make it an ideal choice for craftsmen's favorite craft materials.

Cedar Wood

2. Hardwoods

▶ Alder

Color & Grain : Alder is known for its light brown tan color, which darkens to a deeper reddish - brown when exposed to air. It has a straight and uniform grain.

Carving & Cutting Characteristics : When carved, it offers distinct contrasting shades. Its smooth texture makes it an ideal choice for detailed work.

Linden Wood

▶ Poplar

Color & Grain : Poplar comes in a variety of shades, ranging from cream - yellow to dark brown. The wood has a straight grain and a uniform texture.

Carving & Cutting Characteristics : Its carving effect is similar to that of pine, resulting in black to dark brown tones. According to the technical definition of hardwoods (flowering plants), poplar belongs to the hardwood category. But its hardness is much lower than that of typical hardwoods and is comparable to that of softwoods, so we classify it here. Poplar is commonly used for making furniture, toys, and personalized items. Laser - cutting it will indeed produce noticeable smoke, so an exhaust system needs to be installed.

▶ Linden

Color & Grain : It initially has a light brown or pale white hue, with a consistent and light - colored, uniform - grained appearance.

Carving & Cutting Characteristics : During carving, the shade darkens, making the carvings more prominent and visually appealing.

Any Ideas About Wood for Laser Cutting, Welcome To Discuss With Us!

Related Wood Price

Click on The Title to Go to The Relevant URL

50PCS Cedar Sticks, 100% Aromatic Red Cedar Blocks for Closet Storage

Price: product page$9.99 ($0.20/Count)

Balsa Wood Sheet, 5 Pack Plywood Sheets, Basswood Sheets 12 X 12 X 1/16 Inch

Price: product page$7.99

10 Pieces 10x4cm Natural Pine Unfinished Wood Blocks Rectangle Board for Paintings

Price: product page$9.49

BeaverCraft BW10 Alder Wood Carving Blocks Wood

Price: product page$21.99

8 pcs Large Linden Blocks for Carving and Crafts - 4x4x2 inch DIY Wood Signs

Price: product page$25.19

15 Pack 12 x 12 x 1/16 Inch Poplar Wood Sheets, 1.5mm Craft Wood Sheets

Price: product page$13.99

Wood Applications

Cedar : Used for outdoor furniture and fencing, favored for its natural decay - resistance.

Balsa : Used for insulation and soundproofing, model airplanes, fishing floats, surfboards, and musical instruments, and other crafts.

Pine : Used for furniture and woodworking products, as well as coasters, personalized keychains, photo frames, and small signs.

Pine Wood

Wood Chair

Alder : Commonly used for making crafts that require fine carving and detailed work, as well as decorative parts of furniture.

Linden : Suitable for creating various light - colored and uniformly - grained wooden products, such as small sculptures and decorations.

Poplar : Usually used for making furniture, toys, and personalized items, like custom figurines and decorative boxes.

The Process of Wood Laser Cutting

Since wood is a natural material, consider the characteristics of the type of wood you're using before preparing it for laser cutting. Some woods will deliver better results than others, and some should not be used at all.

Choosing a thinner, low - density wood for laser cutting is best. Thicker wood may not result in a precise cut.

The second step is to design the object you want to cut using your preferred CAD software. Some of the most popular software used for laser cutting includes Adobe Illustrator and CorelDraw.

Make sure to use multiple levels of cut lines when designing. This will make it easier to arrange the layers later when you transfer the design into CAM software. There are various free and paid laser engraving and cutting software options available for CAD, CAM, and control operations.

When preparing your wood for laser cutting, first check if the wood fits into the work area of the laser cutter. If not, cut it down to the necessary size and sand it to remove any sharp edges.

The wood should be free of knots and any other flaws that can lead to uneven cutting. Before beginning to cut, the wood's surface should be well - cleaned and dry because oil or dirt will obstruct the cutting process.

Place the wood flat on the laser bed, ensuring it's stable and properly aligned. Make sure the wood lies flush to avoid uneven cutting. For thin sheets, use weights or clamps to prevent warping.

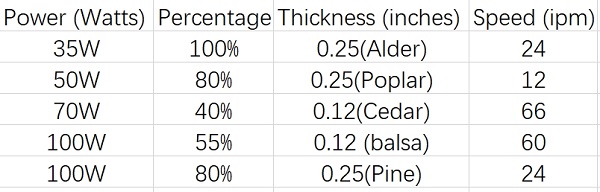

Speed : Determines how fast the laser can cut. The thinner the wood, the higher the speed should be set.

Power : Higher power for hardwood, lower for softwood.

Speed : Adjust to balance between clean cuts and avoiding burns.

Focus : Ensure the laser beam is correctly focused for precision.

Softwood : Can be cut at a quicker speed, and if engraving, it will result in a lighter engraving.

Hardwood : Needs to be cut with a higher laser power than softwood.

Plywood : Made from at least three layers of wood glued together. The type of glue determines how you would prep this wood material.

Tips For Wood Laser Cutting

1. Choose the Right Type of Wood

Avoid using treated lumber that contains chemicals or preservatives, as cutting it can release toxic fumes. Softwoods like larch and fir have uneven grain, making it difficult to set laser parameters and achieve clean engravings. On the other hand, laser cutting MDF, such as Truflat, provides a more consistent and smooth surface since it has no natural grain, making it much easier to work with for precise cuts and detailed designs.

2. Consider Wood Thickness and Density

Both the thickness and density of wood affect laser cutting results. Thicker materials require higher power or multiple passes for effective cutting, while harder or denser woods, such as laser cut plywood, also need adjusted power or extra passes to ensure precise cuts and high-quality engraving. These factors play a crucial role in the cutting process and the final product’s quality.

3. Pay Attention to Wood Carving Characteristics

Softer woods produce less contrast in engraving. Oily woods, such as teak, can cut messily, with a lot of staining in the Heat - Affected Zone (HAZ). Understanding these characteristics helps in managing expectations and adjusting cutting parameters accordingly.

4. Be Mindful of Costs

Higher - quality woods come with higher prices. Balancing the quality of the wood with your project requirements and budget is essential to ensure cost - effectiveness without compromising on the desired outcome.

FAQs For Wood Laser Cutting

The best types of wood for laser cutting are generally lighter woods like basswood, balsa, pine, and alder.

These types render clearer engravings and are easier to work with due to their consistent grain and adequate resin content.

• Adjust the laser speed and power settings.

• Use masking tape to protect the wood surface.

• Ensure proper ventilation.

• Keep the wood moist during the operation.

• Using a honeycomb bed can also reduce flashback burns.

Wood thickness affects how much power and speed are required for the laser to cut through or engrave the wood effectively.Thicker pieces may require slower passes and higher power, while thinner pieces need lower power to prevent burning.

If you want high contrast in your design, woods like maple, alder, and birch are the best choices.

They provide a lighter background that makes the engraved areas stand out more prominently.

While many types of wood can be used for laser cutting, some wood types perform better than others, depending on your project.

As a rule of thumb, the drier and less resin the wood contains, the lighter the cutting edge.

However, some natural wood or wood material is unsuitable for laser cutting. For example, coniferous woods, such as fir, are not usually suitable for laser cutting.

Laser cutters can cut wood with a thickness of up to 30 mm. However, most laser cutters are more effective when the material thickness ranges from 0.5 mm to 12 mm.

Additionally, the thickness of wood that can be cut with a laser cutter largely depends on the wattage of the laser machine. A higher wattage machine can cut through thicker wood faster than a lower wattage one. For best results, go for laser cutters with a wattage of 60-100.

Recommended Machine For Wood Laser Cut

To achieve the best results when cutting polyester, choosing the right laser cutting machine is crucial. MimoWork Laser offers a range of machines that are ideal for laser engraved wood gifts, including:

• Laser Power: 100W / 150W / 300W

• Working Area (W *L): 1300mm * 900mm (51.2” * 35.4 ”)

• Laser Power: 150W/300W/450W

• Working Area (W * L): 1300mm * 2500mm (51” * 98.4”)

• Laser Power: 180W/250W/500W

• Working Area (W * L): 400mm * 400mm (15.7” * 15.7”)

Conclusion

Laser cutting is a highly precise way to shape wood, but the choice of material directly affects the quality and finish of the project. Many workshops rely on a cut wood machine or a laser for cutting wood to handle different wood types such as cedar, balsa, pine, alder, linden, and poplar, each valued for its unique color, grain, and engraving characteristics.

To get clean results, it’s important to select the right wood, prepare designs with multiple cut-line levels, smooth and secure the surface, and carefully adjust the laser settings. Harder or thicker woods may require higher power or multiple passes, while softer woods create lighter engraving contrast. Oily woods can cause stains, and premium woods offer better outcomes but at a higher cost, so it’s key to balance quality with budget.

Burn marks can be minimized by adjusting settings, applying masking tape, ensuring ventilation, lightly moistening the surface, or using a honeycomb bed. For high-contrast engraving, maple, alder, and birch are excellent choices. While lasers can cut wood up to 30 mm thick, the best results are achieved on materials between 0.5 mm and 12 mm.

Any Questions About Wood for Laser Cutting?

Last Updated: September 9, 2025

Post time: Mar-06-2025