Aramid Fabric Laser Cutting and Engraving

It adheres for the tenet “Honest, industrious, enterprising, innovative” to create new products consistently. It regards buyers, success as its own success. Let us develop prosperous future hand in hand for Aramid Fabric Laser Cutting and Engraving, We welcome prospects, organization associations and close friends from all pieces with the globe to get in touch with us and look for cooperation for mutual gains.

It adheres for the tenet “Honest, industrious, enterprising, innovative” to create new products consistently. It regards buyers, success as its own success. Let us develop prosperous future hand in hand for aramid clothing laser cutting, aramid fabric laser cutter, cutting kevlar, fabric laser cutter, how to cut kevlar, how to cut kevlar panels, kevlar cutters, kevlar cutting tools, laser cutting aramid fabric, laser engraving fabric, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

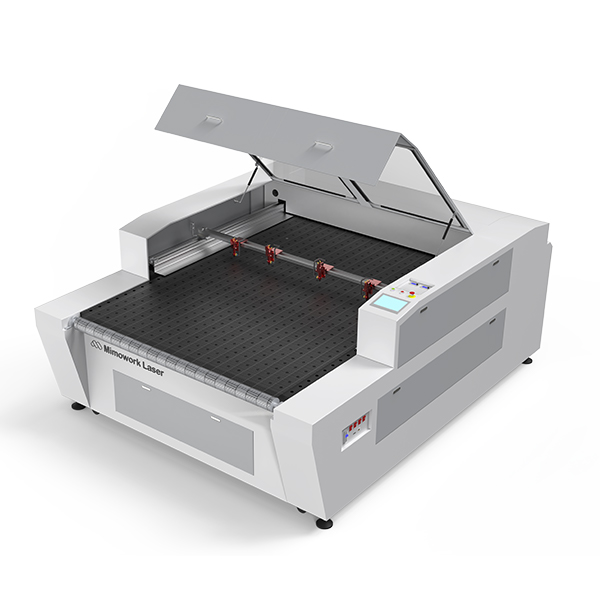

Advantages of Flatbed Laser Cutter

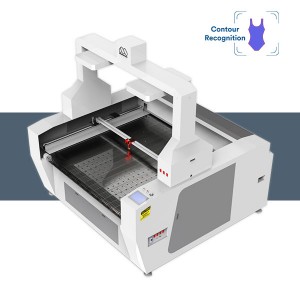

Marking all over your place

Technical Data

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

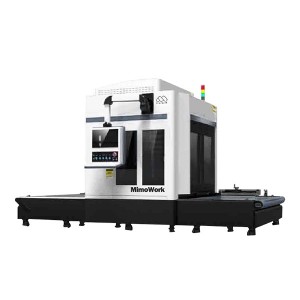

R&D for Flexible Material Cutting

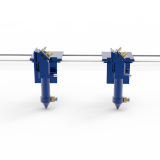

Two Laser Heads

In the simplest and most economic way to double your efficiency is to mount two laser heads on the same gantry and cut the same pattern at the same time. This doesn’t take extra space or labor. If you need to cut a lot of repeat patterns, this would be a good choice for you.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further human intervention.

Video Overview of Laser Cutting & Perforating on Sandpaper

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Customized Marking

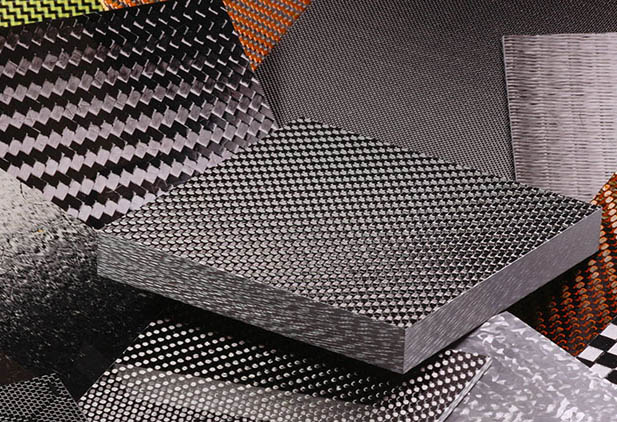

Composite Material

Engraving, marking, and cutting can be realized in single process

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Professional and qualified Laser Cutting Solution for Aramid

Characterized by relatively rigid polymer chains, aramid fibers have great mechanical properties and good resistance to abrasion. Traditional usage of knives is inefficient and the cutting tool wearing causes unstable product quality.

When it comes to aramid products, the large format laser cutter, fortunately, is the most suitable tool for delivering a high level of precision and repeatability accuracy. The contactless thermal processing through the laser beam ensures the sealed cut edges and saves reworking or cleaning procedures.

Benefits from Laser Cutting on Aramid

Clean and sealed cutting edges

✔ High flexible cutting in all direction

✔ Precise cutting results with exquisite details

✔ Automatic processing roll textiles and save labors

✔ No deformation after processing

Material information of Laser Cutting Aramid

Founded in the 60s, Aramid was the first organic fiber with sufficient tensile strength and modulus and was developed as a replacement for steel. Due to its good thermal (high melting point of >500℃) and electrical insulations properties, Aramid Fibers are widely used in aerospace, automotive, industrial settings, buildings, and the military. Personal Protective Equipment (PPE) manufacturers will heavily weave the aramid fibers into the fabric to improve the safety and comfort of workers at all extremes.

Common Aramid brand names:

Kevlar®, Nomex®, and Twaron

With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. “Quality”, “honesty” and “service” is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.