China Laser Cutting Wood Die Board Factories - 1060 Laser Cutter – MimoWork Laser

China Laser Cutting Wood Die Board Factories - 1060 Laser Cutter – MimoWork Laser Detail:

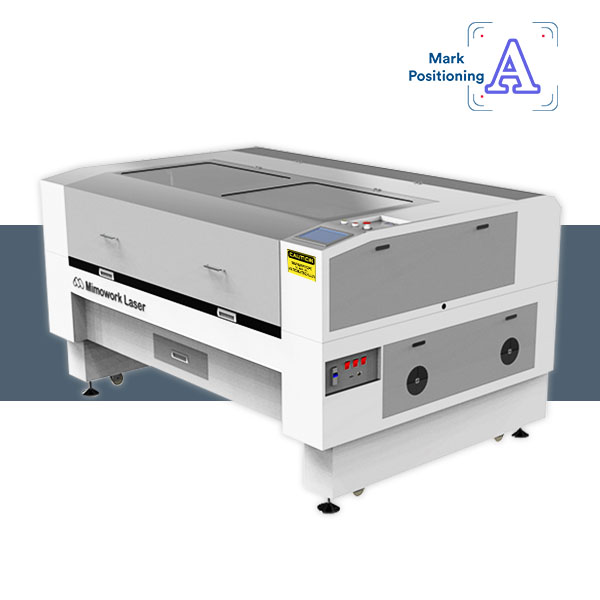

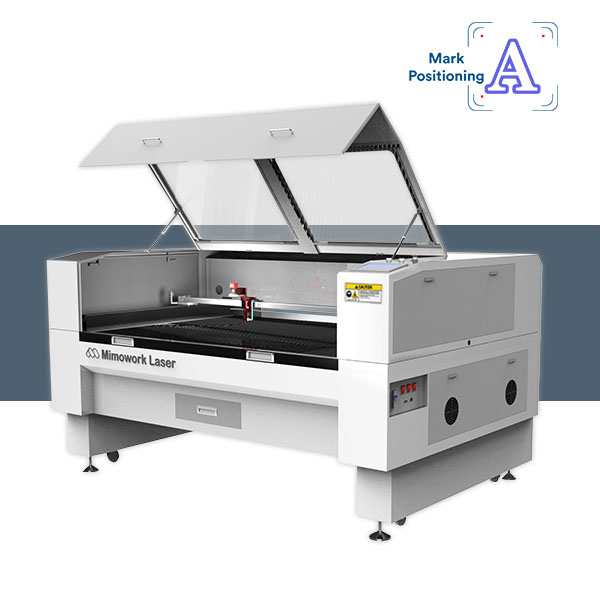

Compact Design, Limitless Creativity

Technical Data

|

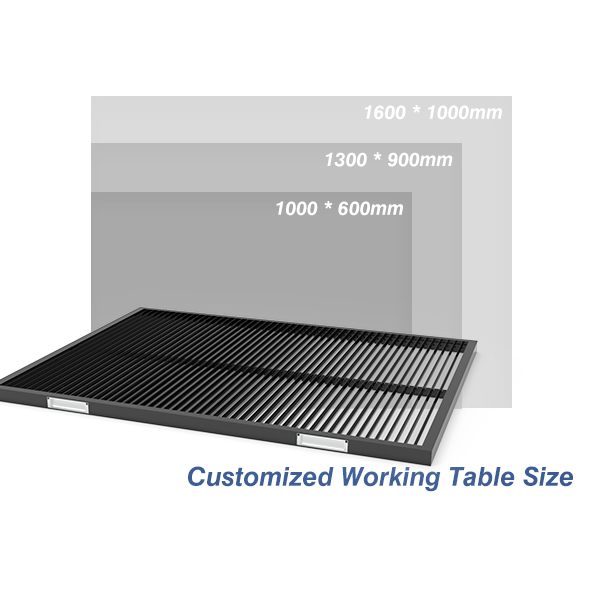

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

40W/60W/80W/100W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

Meet the Beauty of the Modern Engineering

Structure Features & Highlights

◼ Vacuum Table

The vacuum table is an essential component of any laser-cutting machine, and the honeycomb table is ideal for fixing thin paper with wrinkles. This table design ensures that the material remains flat and stable during cutting, resulting in highly accurate cuts. The strong suction pressure provided by the vacuum table is key to its effectiveness in holding materials in place. This feature is especially important for thin, delicate paper that can easily become wrinkled or distorted during cutting. The vacuum table is designed to hold materials in place precisely, allowing for clean, accurate cuts every time.

◼ Air Assist

The air assist feature of a laser cutting machine is designed to blow away smoke and debris from the surface of the paper during the cutting process. This results in a clean and relatively safe cutting finish, without excessive burning or charring of the material. By using air assist, laser cutting machines are able to produce high-quality cuts in a variety of materials. The blowing action of the air assist helps to prevent burning or charring of the material, resulting in a cleaner and more precise cut. In addition, air assist can help to prevent the accumulation of smoke and debris on the surface of the paper, which can be especially problematic when cutting thick materials like cardboard.

Upgradable Options

Rotary Device

The rotary attachment is the perfect solution for engraving cylindrical objects with a precise and uniform dimensional effect. By simply plugging the wire into the designated location, the rotary attachment converts the general Y-axis movement into the rotary direction, providing a seamless engraving experience. This attachment solves the problem of uneven engraved traces caused by the changing distance from the laser spot to the round material’s surface on the plane. With the rotary attachment, you can achieve a more accurate and consistent depth of carving on a variety of cylindrical items, such as cups, bottles, and even pens.

CCD Camera

When it comes to cutting printed paper materials such as business cards, posters, and stickers, achieving accurate cuts along the pattern contour is crucial. This is where the CCD Camera System comes into play. The system provides contour-cutting guidance by recognizing the feature area, making the cutting process much more efficient and precise. The CCD Camera System eliminates the need for manual tracing, saving both time and effort. Moreover, it ensures that the finished product is of high quality and meets the exact requirements of the client. The CCD Camera System is easy to operate and does not require any special skills or training. With its user-friendly interface, the operator can easily set up the system and start using it right away. Additionally, the system is highly reliable and can handle a wide range of materials with ease. Whether you’re working with glossy or matte paper, the CCD Camera System will deliver consistent and accurate results every time.

Servo Motors

A servomotor is an advanced motor that operates on a closed-loop servomechanism, making use of precise position feedback to control its movement and final position. The control input to the servomotor is a signal, which could be either analog or digital, representing the position commanded for the output shaft. To provide position and speed feedback, the motor is typically paired with a position encoder. While in the simplest case, only the position is measured, the output position is compared to the command position, which is the external input to the controller. Whenever the output position differs from the required position, an error signal is generated, causing the motor to rotate in either direction as needed to bring the output shaft to the correct position. As the positions approach, the error signal reduces to zero, causing the motor to stop. In laser cutting and engraving, the use of servo motors ensures higher speed and precision in the process, guaranteeing that the final product is of the highest quality.

Brushless DC Motors

The brushless DC motor is a high-speed motor that can operate at a high RPM. It consists of a stator that generates a rotating magnetic field to drive the armature. Compared to other motors, the brushless DC motor provides the most powerful kinetic energy, making it ideal for driving the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor that enables it to reach a maximum engraving speed of 2000mm/s. Although brushless motors are not commonly used in CO2 laser cutting machines, they are highly effective for engraving materials. This is because the speed of cutting through a material is limited by its thickness. However, when engraving graphics, only a small amount of power is required, and a brushless motor equipped with a laser engraver can significantly reduce engraving time while ensuring greater accuracy.

<a href="https://www.mimowork.com/laser/key-facts-you-need-to-konw-about-co2-laser-machine" title=">> More details about motors” target=”_blank”>

>> More details about motors

Unlock the Secrets of Precision & Speed with MimoWork’s Cutting-Edge Laser Technology

Tell Us Your Requirements

Video Display

▷ Acrylic LED Display Laser Engraving

▷ Best Laser Engraver for Wood

▷ How to Laser Cut Paper

CO2 laser cutting paper offers several benefits such as precise and intricate cuts, clean edges, the ability to cut complex shapes, speed, and versatility in handling various paper types and thicknesses. Additionally, it minimizes the risk of paper tearing or distortion and reduces the need for additional finishing processes, ultimately leading to a more efficient and cost-effective production process.

<a href="https://www.mimowork.com/laser-cutting-paper/" title=">> Paper Laser Cutting” target=”_blank”>

>> Paper Laser Cutting

Find more videos about our laser cutters at our Video Gallery

Compatible wood materials:

MDF, Plywood, Bamboo, Balsa Wood, Beech, Cherry, Chipboard, Cork, Hardwood, Laminated Wood, Multiplex, Natural Wood, Oak, Solid Wood, Timber, Teak, Veneers, Walnut…

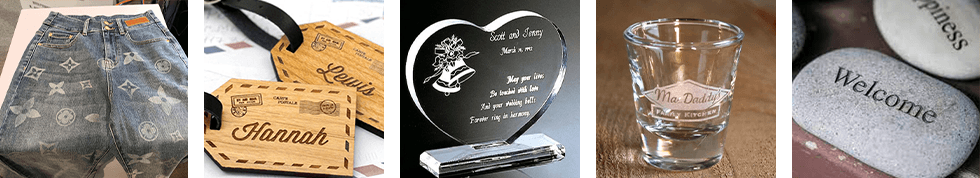

Samples of Laser Engraving

Paper, Painted Metal, Laminate

Related Laser Cutting Machine

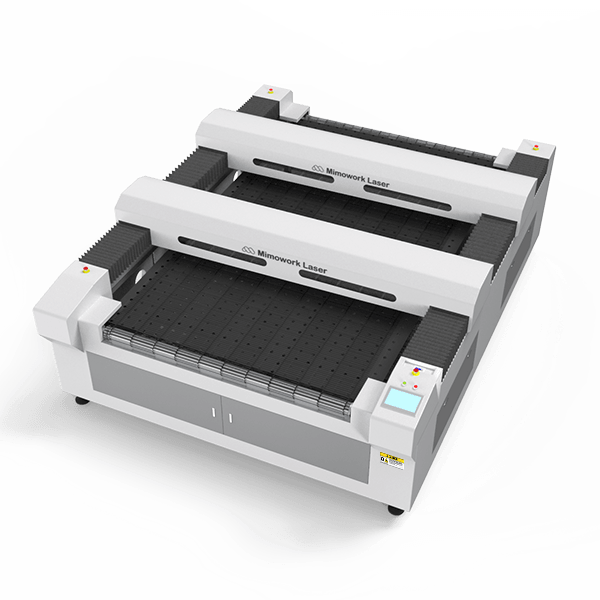

Large Laser Cutter for acrylic & wood

• Working Area (W * L): 1300mm * 2500mm

• Laser Power: 150W/300W/500W

Mimowork Provides:

Professional and Affordable Laser Machine

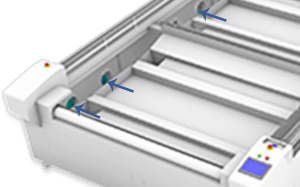

Fabric Laser Cutter

• Working Area (W * L): 1600mm * 1000mm

• Laser Power: 100W/150W/300W

Transform Your Ideas into Reality – With Mimowork by your Side

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and together with the top-quality good quality solutions, favorable selling price and superior after-sales providers, we try to acquire each customer's rely on for China Laser Cutting Wood Die Board Factories - 1060 Laser Cutter – MimoWork Laser , The product will supply to all over the world, such as: Adelaide , Hanover , Mozambique , We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!