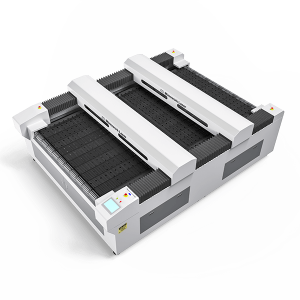

100W Laser Cutter

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* More sizes of laser working table are customizable

* Higher Power Laser Tube are customizable

▶ FYI: The 100W Laser Cutter is suitable to cut and engrave on solid materials such as acrylic and wood. Honey comb working table and knife strip cutting table can carry the materials and help to reach best the cutting effect without dust and fume that can be sucked into and purified.

Video of Laser Cutting Basswood Board

Turning Basswood into 3D Eiffel Tower Model

This 100W Laser Cutter can cut out complex, detailed shapes with clean and burn-free results. The keyword here is precision, accompanied by great cutting speed. When cutting wood boards as we showed in the video, you can't go wrong with a laser cutter like this.

Highlights from Basswood Laser Cutting

✔ Flexible processing for any shape or pattern

✔ Perfectly polished clean cutting edges in a single operation

✔ No need to clamp or fix the Basswood due to contactless processing

Find more videos about our laser cutters at our Video Gallery

Unique advantages of laser cutting

✔ Clean and smooth edges with thermal sealing when processing

✔ No limitation on shape, size, and pattern realizes flexible customization

✔ Customized laser tables meet requirements for varieties of materials formats

Want to learn more about Laser Cutting Wood?

Tips and Tricks to achieve Prefection

1. Higher purity acrylic sheet can achieve better cutting effect.

2. The edges of your pattern should not be too narrow.

3. Select the laser cutter with the right power for flame-polished edges.

4. The blowing should be as slight as possible to avoid heat diffusion which could also lead to burning edge.