Laser Engraving Machine for Denim

We’ve been experienced manufacturer. Wining the majority of your crucial certifications of its market for Laser Engraving Machine for Denim, As a key organization of this industry, our corporation makes initiatives to become a leading supplier, according to the faith of qualified top quality & around the globe service.

We’ve been experienced manufacturer. Wining the majority of your crucial certifications of its market for denim laser engraving, denim laser engraving machine, denim laser engraving service, Denim laser print, Denim laser printing, jeans laser machine, Jeans machine, laser cutter jeans, laser cutting jeans, Laser Denim Engraving Machine, laser engraved denim, laser engraved jeans, laser engraving machine for denim, laser on denim, laser print denim, laser print on denim, laser printing on denim, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it’s a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

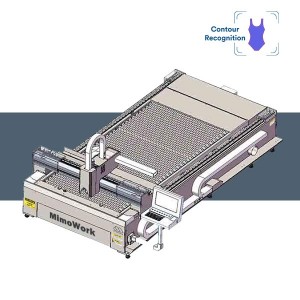

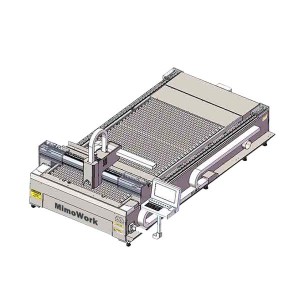

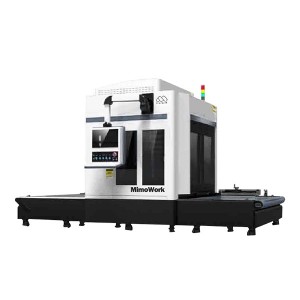

ADVANTAGES OF GALVO LASER ENGRAVER & MARKER 40

Best Entry-level GALVO Laser Machine

Technical Data

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

| Laser Source | CO2 RF Metal Laser Tube |

| Mechanical System | Servo Driven, Belt Driven |

| Working Table | Honey Comb Working Table |

| Max Cutting Speed | 1~1000mm/s |

| Max Marking Speed | 1~10,000mm/s |

Highlight of GALVO Laser Engraver & Marker 40

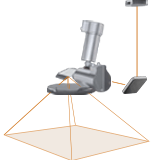

GALVO Head

GALVO laser uses high-speed, motor-driven mirrors to steer the laser beam through the lens. Aiming at the material in the laser marking field, the beam impacts the material at a greater or lesser inclination angle. The marking field size is defined by the deflection angle and the focal length of the optics. As there is no mechanical movement during cutting (with the exception of the mirrors), the laser beam can be guided over the workpiece at an extremely high speed. High efficiency and at the same time, high precision, make GALVO Laser Engraver & Marker 40 an ideal marking machine when it comes to short cycle times or high-quality markings.

For other GALVO views, diverse GALVO lenses are available. The biggest GALVO lens for this model is up to 800mm.

Fields of Application

Laser Cutting for Your Industry

Kiss Cutting

A laser tech that is widely used in many industries

Common materials and applications

of GALVO Laser Engraver & Marker 40

We’ve designed laser systems for dozens of clients

Add yourself to the list!

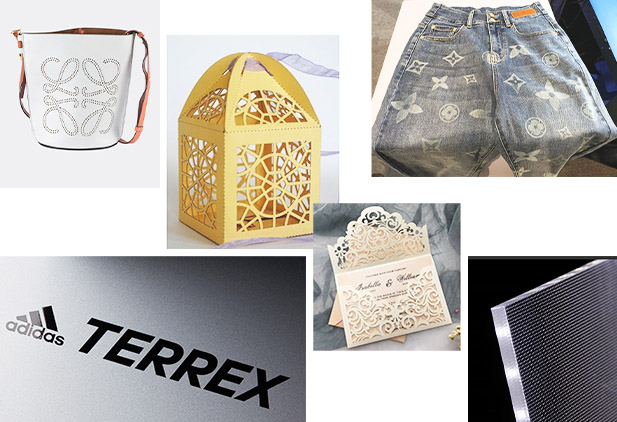

Denim Fabric Laser Processing

(laser marking, cutting, perforating)

Professional and qualified Laser Solution for Denim

As an enduring classic, denim cannot be considered a trend, it will never go in and out of fashion. Denim elements have always been the classic design theme of the clothing industry, deeply loved by designers, denim clothing is the only popular clothing category in addition to the suit. For jeans-wearing, tearing, aging, dying, perforating and other alternative decoration forms are the signs of punk, hippie movement. With unique cultural connotations, denim gradually became cross-century popular, and gradually developed into a worldwide culture.

MimoWork Laser Machine provides customized laser solutions for denim fabric manufacturers. You can realize laser marking, laser engraving, laser perforating, laser cutting on denim fabric. High efficient and flexible laser processing assists denim fashion diversely moving on!

With Galvo Laser Marker

Denim Fabric Laser Marking

✦ Ultra-speed and fine laser marking

✦ Auto-feeding and marking with conveyor system

✦ Upgraded extensile working table for different material formats

Laser processing for Denim Fabric

denim-laser-processing-02

1. Laser Cutting & Perforating on Denim

Denim fabric is very durable. The textile is compact and thick. The shrinkage ratio is smaller than ordinary fabric. Cutting by traditional methods may cause a ladder.

>> learn more laser cutting

denim-laser-processing-04

2. Laser Marking (Engraving) on Denim

You don’t have to wash the denim to get the aging/whisker/monkey wash effect. Free your big washing machines from easy works and let the laser machine do the job for you. A more competitive price can help to do the job, achieving diverse effects on the denim fabric.

>> learn more laser engraving

Other process techniques

The laser can burn the surface textile off the denim fabric to expose the original color of the cloth. Denim with the effect of rendering can also be matched with different fabrics, such as wool, imitation leather, corduroy, thick knitting (wool, hoodie cloth), and so on.

Material information of Denim Laser Processing

denim-laser

The concept of environmentally friendly, sustainable and regenerative design is increasingly recognized in the fashion industry and has become an irreversible new trend. This concept is particularly evident in the transformation of Denny denim fabric. The essence of denim fabric transformation is to pay more attention to environmental protection, natural materials and creative recycling while maintaining the design value. The various techniques used by designers and manufacturers, such as embroidery and printing, both cater to fashion trends and conform to the concept of green fashion.

Laser can minimize manual operation in denim processing and minimize environmental pollution. Moreover, MimoWork with laser vision technology can help you achieve these manufacturing techniques.

Typical applications for Laser Processing Denim

• Apparel

- jeans

- jacket

- vest

- skirt

• Shoes

• Bags

• Home textiles

• Toy fabrics