Nylon Laser Cutting Machine of large format

Attaining consumer satisfaction is our firm’s purpose for good. We’ll make wonderful efforts to produce new and top-quality merchandise, meet up with your special necessities and supply you with pre-sale, on-sale and after-sale products and services for Nylon Laser Cutting Machine of large format, We warmly welcome domestic and overseas customers send out inquiry to us ,we’ve 24hours doing work staff! Anytime anywhere we are still here to generally be your partner.

Attaining consumer satisfaction is our firm’s purpose for good. We’ll make wonderful efforts to produce new and top-quality merchandise, meet up with your special necessities and supply you with pre-sale, on-sale and after-sale products and services for Co2 laser stippling, how to cut nylon, how to laser engrave polymer, laser cut nylon sheet, Laser cutting nylon, Laser cutting pa, nylon cutter, Nylon cutter machine, nylon cutting, Nylon cutting machine, nylon laser cutting, nylon sheet cut to size, Our mission is “Provide Goods with Reliable Quality and Reasonable Prices”. We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Advantages of Commercial Laser Cutter

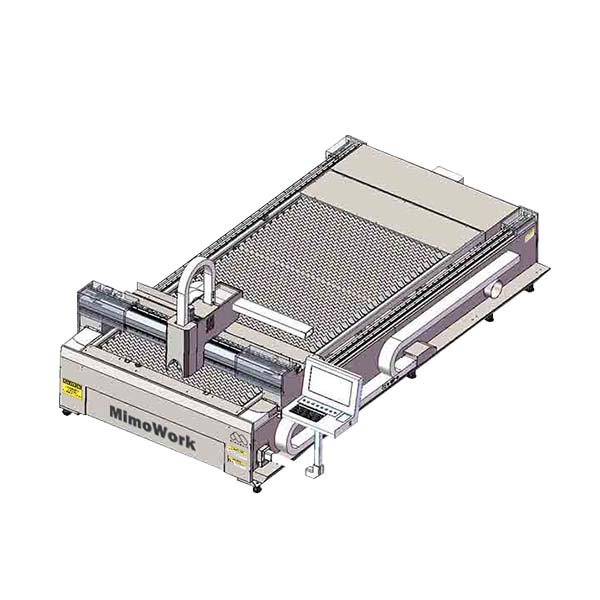

Ultimate Large Fabric Cutter

Technical Data

| Working Area (W * L) | 2500mm * 3000mm (98.4’’ *118’’) |

| Max Material Width | 98.4’’ |

| Software | Offline Software |

| Laser Power | 150W/300W/500W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack and Pinion Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

(Upgrade for your industrial fabric laser cutting machine, textile laser cutter)

Ideal for Technical Textile Laser Cutting

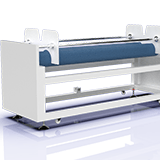

Auto Feeder

Auto Feeder is a feeding unit that runs synchronously with the laser cutting machine. The feeder will convey the roll materials to the cutting table after you put the rolls on the feeder. Feeding speed can be set according to your cutting speed. A sensor is equipped to ensure perfect material positioning and minimize errors. The feeder is able to attach different shaft diameters of rolls. The pneumatic roller can adapt textiles with various tension and thickness. This unit helps you to realize a completely automatic cutting process.

![]()

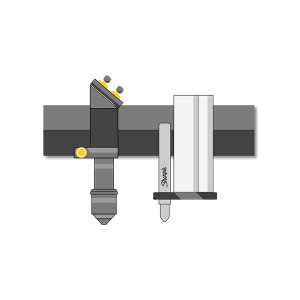

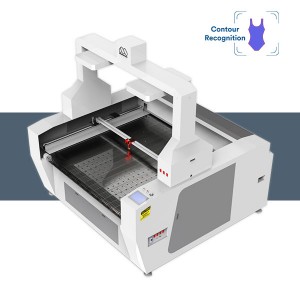

Vision System

When you are trying to cut out the contours, no matter printing contour or embroidery contour, you may need the Vision System to read the contour or special data for positioning and cutting. Varied options have been designed in our software packages such as contour scanning and marks scanning, serving diverse applications and requirements.

Ink-Jet Printing

Ink-Jet Printing is widely used for marking and coding products and packages. A high-pressure pump directs liquid ink from a reservoir through a gun-body and a microscopic nozzle, creating a continuous stream of ink droplets via the Plateau-Rayleigh instability. The ink-jet printing technology is a non-contact process and has a wider application in terms of different types of materials. Moreover, inks are also options, like volatile ink or non-volatile ink, MimoWork loves to help to choose according to your needs.

Video Glance of Laser Cutting Filter Cloth

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Composite Material

Engraving, marking, and cutting can be realized in single process

Clothing & Home Textiles

Clean and smooth edge with thermal treatment

Outdoor Equipment

Your popular and wise manufacturing direction

Automotive & Aviation

The secret of exquisite pattern cutting

Common materials and applications

of Flatbed Laser Cutter 250L

Learn more industrial fabric laser cutter price

Let’s know your requirements!

Attaining consumer satisfaction is our firm’s purpose for good. We’ll make wonderful efforts to produce new and top-quality merchandise, meet up with your special necessities and supply you with pre-sale, on-sale and after-sale products and services for Factory Price China Automatic Computer Controlled Fabric Cutter Machine, We warmly welcome domestic and overseas customers send out inquiry to us ,we’ve 24hours doing work staff! Anytime anywhere we are still here to generally be your partner.

Application of Laser Cutting Nylon

• Seatbelt

• Ballistic Equipment

• Clothing and Fashion

• Military Clothing

• Synthetic Textiles

• Medical Device

• Interior Design

• Tents

• Parachutes

• Package

nylon-cutting-application-02

Material information of Laser Cutting Nylon

nylon-02

Firstly successfully being commercialized as synthetic thermoplastic polymer, nylon 6,6 are launched by DuPont as military clothing, synthetic textiles, medical devices. With high resistance of abrasion, high tenacity, rigidity and toughness, elasticity, nylon can be melt-processed into different fibers, films, or shape and play versatile roles in apparel, flooring, electrical equipment and molded parts for automotive and aviation. Combined with blending and coating technology, nylon has developed many variations. Nylon 6, nylon 510, nylon-cotton, nylon-polyester are taking on responsibilities in various occasions. As an artificial composite material, nylon can be perfectly cut on Fabric Laser Cut Machine. No worry about material distortion and damage, laser systems featured by contactless and forceless processing. Superior colorfastness and dying for varieties of colors, printed and dyed nylon fabrics can be laser cut into accurate patterns and shapes. Supported by Recognition Systems, laser cutter will be your good helper in processing nylon materials.

Other terms of Nylon

CORDURA®, Kevlar®, Polyester, Composite Materials

Nylon Laser Cutting

Professional and qualified Laser Cutting solution for Nylon

nylon-04

Parachutes, activewear, ballistic vest, military clothing, the familiar nylon-made products all can be laser cut with the flexible and precise cutting method. Non-contact cutting on nylon avoids material distortion and damage. Thermal treatment and accurate laser power deliver dedicated cutting results for cutting nylon sheet, ensuring clean edge, eliminating the trouble of secondary burr-processing. MimoWork laser systems provide customers with suitable customized laser solutions for different requirements(various nylon variations, different sizes, and shapes).

How to cut Nylon with the Fabric Laser Cutting Machine?

CO2 laser source with 9.3 and 10.6 micron wavelength is prone to be partly absorbed by nylon materials to melt the material by photothermal conversion. Additionally, flexible and varied processing methods can create more possibilities for nylon articles, including laser cutting and laser engraving. Inherent processing feature of laser system has been no stopping the pace of innovating for customers’ more demands.

Laser processing for Nylon

laser-cutting-nylon-01

1. Laser Cutting Nylon

Cutting nylon sheets to size within 3 steps, the CNC laser machine can clone the design file to 100 percent.

1. Place the nylon fabric on the working table;

2. Upload the cutting file or design the cutting path on the software;

3. Start the machine with the appropriate setting.

2. Laser Engraving on Nylon

In industrial production, marking is a common requirement for product type identification, data management, and affirming the right location to stitch the next sheet of material for a follow-up procedure. Laser engraving on nylon materials can perfectly solve the trouble. Importing the engraving file, setting the laser parameter, pressing the start button, the laser cutting machine then engrave the drill hole marks on the fabric, to mark the placement of things like Velcro pieces, to later be sewn on top of the fabric.

laser-perforating-nylon-01

3. Laser Perforating on Nylon

Thin but powerful laser beam can fast perforate on nylon including blended, composite textiles to conduct dense and different sizes & shapes holes, while no any materials adhesion. Tidy and clean without post-processing.

Why laser cut nylon sheet?

clean-eage-cutting-01

Clean edge for any angles

fine-small-holes-perforating

Fine small holes with high repeataion

large-format-cutting

Large format cutting for customized sizes

✔ Sealing the edges guarantees clean and flat edge

✔ Any pattern and shape can be laser cut

✔ No fabric deformation and damage

✔ Constant and repeatable cutting quality

✔ No tool abrasion and replacement

✔ Customized table for any size of materials