Understanding how laser galvo works is key to mastering modern laser systems. Laser galvo uses fast-moving galvanometer mirrors to guide the laser beam across surfaces with precision and speed. This setup enables accurate engraving, marking, and cutting on various materials, making it a preferred solution in high-efficiency production environments.

This video offers a deep dive into the working principle of a “Galvo” system—short for galvanometer scanner—used in laser engraving machines. It begins by explaining the key components of the Galvo system: two fast-moving mirrors (on the X and Y axes) that precisely direct the laser beam. The video then demonstrates real-time engraving on materials like wood and paper, highlighting the system’s advantages in speed and accuracy.

Deep Dive into Galvo Laser, Refer to the Following:

Galvo Scanner

At the heart of a galvo laser system is the galvanometer scanner, often called a galvo scanner. This device uses mirrors controlled by electromagnetic signals to rapidly direct the laser beam.

Laser Source

The laser source emits a high-intensity beam of light, usually in the infrared spectrum for industrial applications.

Mirror Movement

The galvo scanner rapidly moves two mirrors in different axes, typically X and Y. These mirrors reflect and steer the laser beam precisely across the target surface.

Vector Graphics

Galvo lasers often work with vector graphics, where the laser follows specific paths and shapes outlined in digital designs. This allows for precise and intricate laser marking or cutting.

Pulse Control

The laser beam is often pulsed, meaning it turns on and off rapidly. This pulse control is crucial for controlling the depth of laser marking or the intensity of laser cutting.

Galvo Laser Scanner for Galvo Laser Engraver

The GALVO head can be adjusted vertically for you to achieve different laser beam sizes according to the size of your material. The maximum working view of this Galvo laser system can reach 400mm * 400 mm. Even in a maximum working area, you can still get a finest laser beam to 0.15 mm for the best laser engraving and marking performance.

As MimoWork laser options, the Red-Light Indication System and CCD Positioning System work together to correct the center of the working path to the real position of the piece during galvo laser working. Moreover, the version of the Full Enclosed design can be requested to meet the class 1 safety protection standard of galvo laser engraver.

Suitable for:

The large format laser engraver is R&D for large size materials laser engraving & laser marking. With the conveyor system, the galvo laser engraver can engrave and mark on roll fabrics (textiles). You can regard it as a fabric laser engraving machine, laser denim engraving machine, leather laser engraving machine to extend your business. EVA, carpet, rug, mat can all be laser engraver by the Galvo Laser.

Suitable for:

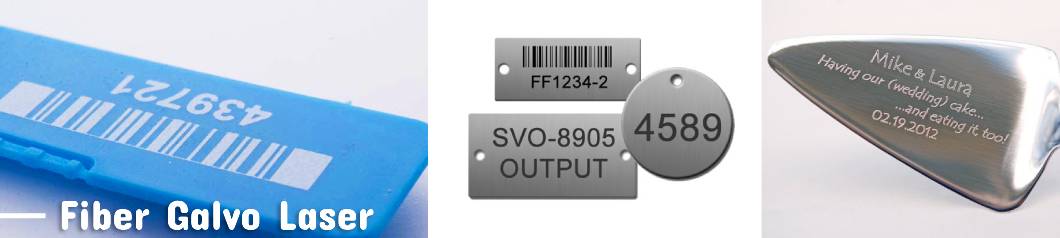

The fiber laser marking machine uses laser beams to make permanent marks on the surface of various materials. By evaporating or burning off the surface of the material with light energy, the deeper layer reveals then you can get a carving effect on your products. Whether how complex the pattern, text, bar code, or other graphics are, the MimoWork Fiber Laser Marking Machine can etch them on your products to meet your needs for customization.

Besides, we have a Mopa Laser Machine and a UV Laser Machine for you to choose from.

Suitable for:

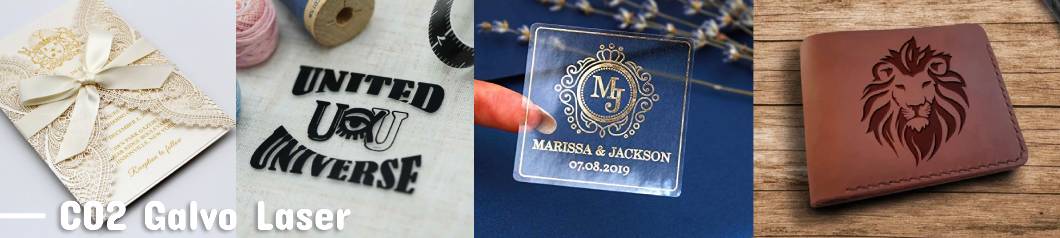

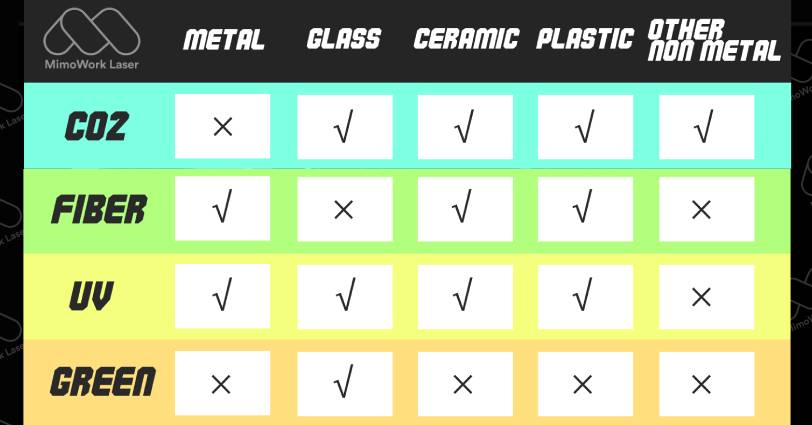

◼ Galvo Laser Engraving & Marking

Galvo laser is the king of speed, with the help of the fine and agile laser beam, can quickly pass through the material's surface and leave precise engraving and etching marks. Such as the etched patterns on the jeans, and marked logo on the nameplate, you can use galvo laser to easily realize mass production and customized design. Due to different laser sources working with galvo laser systems like CO2 Laser, Fiber Laser, and UV Laser, galvo laser engraver is compatible with various materials. Here is a table for brief explanation.

◼ Galvo Laser Cutting

In general, galvo scanner is installed in the laser machine, as a galvo laser engraver or laser marking machine, that can complete the fast engraving, etching, and marking on various materials. Due to the wobbled lens, the Galvo laser machine is pretty agile and quick to transmit and move the laser beam, coming with super fast engraving and marking on the surface of materials.

However, the sensitive and precise laser light cuts off like a pyramid, making it unable to cut thick materials like wood cause there will be a slope at the cut. You can see the animation demonstration of how the cut slope is created in the video. What about thin materials? Galvo Laser is capable of cutting thin materials like paper, film, vinyl and thin fabrics. Like Kiss Cut vinyl, the galvo laser stands out in a crowd of tools.

✔ Galvo Laser Engraving Denim

Are you looking to add a unique touch to your denim garments? Look no further than Denim Laser Engraver, your ultimate solution for personalized denim customization. Our innovative application utilizes cutting-edge CO2 galvo laser technology to create intricate designs, logos, and patterns on denim fabric with unparalleled precision and efficiency. With galvanometer-controlled mirrors, galvo laser engraving process is fast and efficient, enabling quick turnaround times for your denim customization projects.

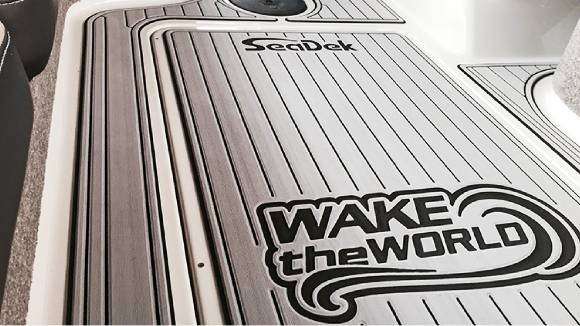

✔ Galvo Laser Engraving Mat (Carpet)

Galvo laser engraving technology offers a versatile solution for customizing carpets and mats with precision and creativity. Whether for commercial branding, interior design, or personalization purposes, the applications are endless. Businesses can utilize laser engraving to imprint logos, patterns, or text onto carpets used in corporate offices, retail spaces, or event venues, enhancing brand visibility and professionalism. In the realm of interior design, homeowners and decorators can add personalized touches to rugs and mats, elevating the aesthetic appeal of residential spaces with custom designs or monograms.

✔ Galvo Laser Engraving Wood

Galvo laser engraving on wood presents a myriad of possibilities for both artistic expression and functional applications. This innovative technology utilizes high-powered CO2 lasers to precisely etch designs, patterns, or text onto wooden surfaces, ranging from hardwoods like oak and maple to softer woods such as pine or birch. Artisans and craftsmen can create intricate designs on wooden furniture, signage, or decorative items, adding a touch of elegance and uniqueness to their creations. Additionally, laser-engraved wooden gifts, such as personalized cutting boards or photo frames, offer a thoughtful and memorable way to commemorate special occasions.

✔ Galvo Laser Cutting Holes in Fabric

In the fashion industry, designers use galvo laser cutting to add unique textures and designs to garments, such as lace-like patterns, perforated panels, or intricate cutouts that enhance the aesthetic appeal of clothing. This technology is also extensively used in textile manufacturing for creating ventilation holes in sportswear and activewear, improving breathability and comfort for athletes and outdoor enthusiasts. Additionally, galvo laser cutting enables the production of decorative fabrics with custom patterns and perforations for interior design applications, including upholstery, curtains, and decorative textiles.

✔ Galvo Laser Cutting Paper

From elegant invitations to decorative stationery and intricate paper art, galvo laser cutting enables precise cutting of intricate designs, patterns, and shapes on paper. Laser cutting paper is widely used in creating personalized invitations for weddings and special events, decorative stationery items like greeting cards and letterheads, as well as intricate paper art and sculptures. Additionally, galvo laser cutting is utilized in packaging design, educational materials, and event decorations, showcasing its versatility and precision in various industries and applications.

✔ Galvo Laser Cutting Heat Transfer Vinyl

Galvo laser cutting technology is a game-changer in the heat transfer vinyl (HTV) industry, offering precise and efficient cutting solutions for both kiss cut and full cut applications. With kiss laser cutting, the laser accurately cuts through the top layer of HTV without penetrating the backing material, making it ideal for creating custom decals and stickers. On the other hand, full cutting involves cutting through both the vinyl and its backing, producing ready-to-apply designs for apparel decoration with clean edges and intricate details. Galvo laser cutting enhances precision, efficiency, and versatility in HTV applications, allowing for the creation of personalized designs, logos, and patterns with sharp edges and minimal waste.

Step 1. Put the Material

▶

Step 2. Set Laser Parameters

▶

Step 3. Galvo Laser Cut

Some Suggestions While Using Galvo Laser

1. Material Selection:

Choose the right material for your engraving project. Different materials react differently to laser engraving, so consider factors such as material type, thickness, and surface finish for optimal results.

2. Test Runs:

Always perform test runs on a sample piece of material before engraving the final product. This allows you to fine-tune laser settings, such as power, speed, and frequency, to achieve the desired engraving depth and quality.

3. Safety Precautions:

Prioritize safety by wearing appropriate protective gear, such as safety glasses, when operating the galvo laser engraving machine. Follow all safety guidelines provided by the manufacturer.

4. Ventilation and Exhaust:

Ensure proper ventilation and exhaust systems are in place to remove fumes and debris generated during the engraving process. This helps maintain a clean and safe working environment.

5. File Preparation:

Prepare your engraving files in compatible formats for the laser engraving software. Ensure the design is correctly scaled, positioned, and aligned with the material to avoid misalignment or overlapping during engraving.

A galvo laser, short for galvanometer laser, refers to a type of laser system that utilizes galvanometer-controlled mirrors to direct and control the laser beam's position and movement. Galvo lasers are commonly used in laser marking, engraving, cutting, and scanning applications due to their high speed, precision, and versatility.

Yes, galvo lasers can cut materials, but their primary strength lies in marking and engraving applications. Galvo laser cutting is typically used for thinner materials and more delicate cuts compared to other laser cutting methods.

A galvo laser system is primarily designed for high-speed laser marking, engraving, and cutting applications. It uses galvanometer-controlled mirrors to rapidly and precisely move the laser beam, making it ideal for precise and detailed marking on various materials like metals, plastics, and ceramics. On the other hand, a laser plotter, also known as a laser cutting and engraving machine, is a versatile system used for a wide range of cutting, engraving, and marking tasks. It uses motors, such as stepper or servo motors, to control the movement of the laser head along X and Y axes, allowing for controlled and precise laser processing on materials like wood, acrylic, metal, fabric, and more.

> What information you need to provide?

> Our contact information

About MimoWork Laser

Mimowork is a results-oriented laser manufacturer, based in Shanghai and Dongguan China, bringing 20 years of deep operational expertise to produce laser systems and offer comprehensive processing and production solutions to SMEs (small and medium-sized enterprises) in a wide array of industries.

Our rich experience of laser solutions for metal and non-metal material processing is deeply rooted in the worldwide advertisement, automotive & aviation, metalware, dye sublimation applications, fabric and textiles industries.

Rather than offering an uncertain solution that requires purchase from unqualified manufacturers, MimoWork controls every single part of the production chain to make sure our products have constant excellent performance.

Quickly Learn More:

Learn More about Galvo Laser Marking,

Click here to talk with us!

Post time: Apr-22-2024