Laser Deserves The Perfect One for Cutting Acrylic! Why do I say that? Because of its wide compatibility with different acrylic types and sizes, super high precision and fast speed in cutting acrylic, easy to learn and operate, and more. Whether you are a hobbyist, cutting acrylic products for business, or for industrial use, laser cutting acrylic meets almost all the requirements. If you are pursuing excellent quality and high flexibility, and want to master quickly, acrylic laser cutter will be your first choice.

Advantages of Laser Cutting Acrylic

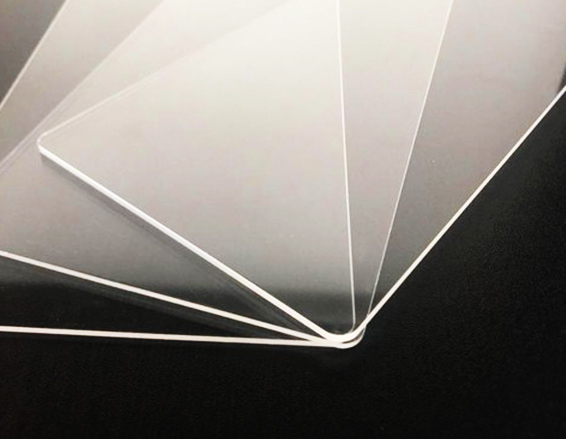

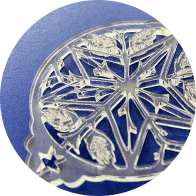

✔ Smooth Cutting Edge

The powerful laser energy can instantly cut through the acrylic sheet in a vertical direction. The heat seals and polishes the edge into being smooth and clean.

✔ Non-Contact Cutting

Laser cutter features contactless processing, getting rid of the worry about material scratches and cracking because there is no mechanical stress. No need to replace tools and bits.

✔ High Precision

Super high precision makes acrylic laser cutter cut into intricate patterns according to the designed file. Suitable for exquisite custom acrylic decor and industrial & medical supplies.

✔ Speed and Efficiency

Strong laser energy, no mechanical stress, and digital auto-control, greatly increase the cutting speed and the whole production efficiency.

✔ Versatility

CO2 laser cutting is versatile to cut acrylic sheets of various thicknesses. It is suitable for both thin and thick acrylic materials, providing flexibility in project applications.

✔ Minimal Material Waste

The focused beam of a CO2 laser minimizes material waste by creating narrow kerf widths. If you are working with mass production, the intelligent laser nesting software can optimize the cutting path, and maximize the material use rate.

Crystal-clear edge

Intricate cut pattern

Engraved photos on acrylic

▶ Get A Closer Look at: What is Laser Cutting Acrylic?

Laser Cutting An Acrylic Snowflake

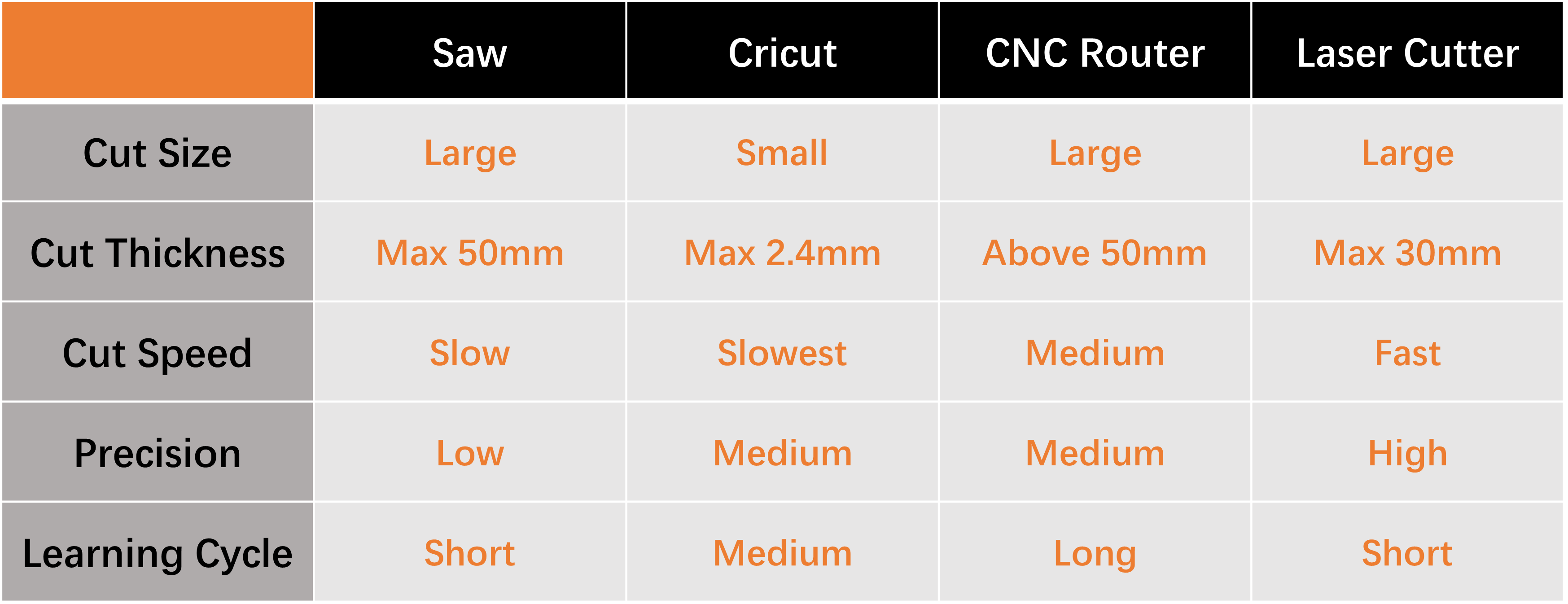

4 Cutting Tools - How to Cut Acrylic?

Jigsaw & Circular Saw

A saw, such as a circular saw or jigsaw, is a versatile cutting tool commonly used for acrylic. It's suitable for straight and some curved cuts, making it accessible for DIY projects and larger-scale applications.

Cricut

A Cricut machine is a precision cutting tool designed for crafting and DIY projects. It uses a fine blade to cut through various materials, including acrylic, with accuracy and ease.

CNC Router

A computer-controlled cutting machine with a range of cutting bits. It's highly versatile, capable of handling various materials, including acrylic, for both intricate and large-scale cutting.

Laser Cutter

A laser cutter employs a laser beam to cut through acrylic with high precision. It is commonly used in industries requiring intricate designs, fine details, and consistent cutting quality.

How to Choose Acrylic Cutter Suits You?

cause its

Versatility, Flexibility, Efficiency …

☻ Excellent Laser Ability of Cutting Acrylic:

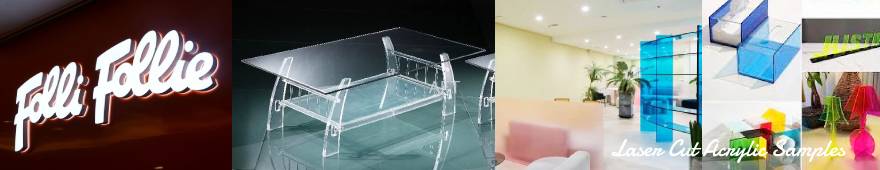

Some Samples of Laser Cutting Acrylic

• Ads Display

• Storage Box

• Signage

• Trophy

• Model

• Keychain

• Cake Topper

• Gift & Decor

• Furniture

• Jewelry

▶ Is Laser Cutting Acrylic Toxic?

▶ How To Laser Cut Clear Acrylic?

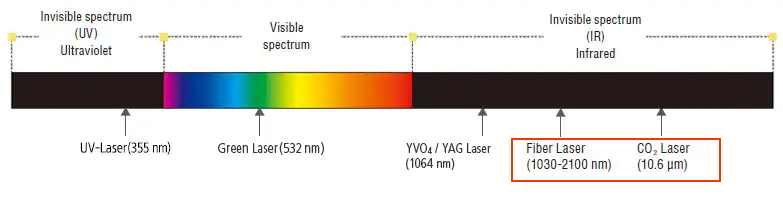

▶ What is The Best Laser for Acrylic Cutting?

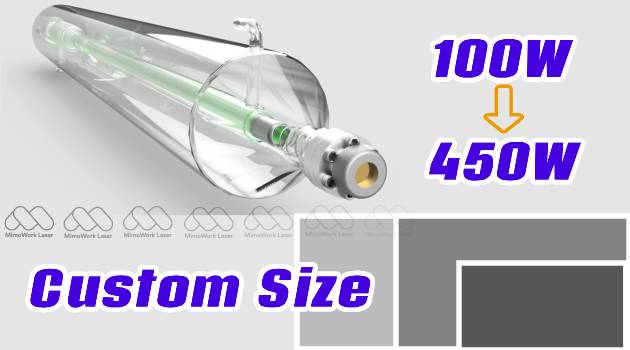

For acrylic cutting specifically, a CO2 laser is often considered the best choice due to its wavelength characteristics, providing clean and precise cuts across various acrylic thicknesses. However, the specific requirements of your projects, including budget considerations and the materials you plan to work with, should also influence your choice. Always check the specifications of the laser system and ensure it aligns with your intended applications.

▶ Recommended CO2 Laser Cutter for Acrylic

From MimoWork Laser Series

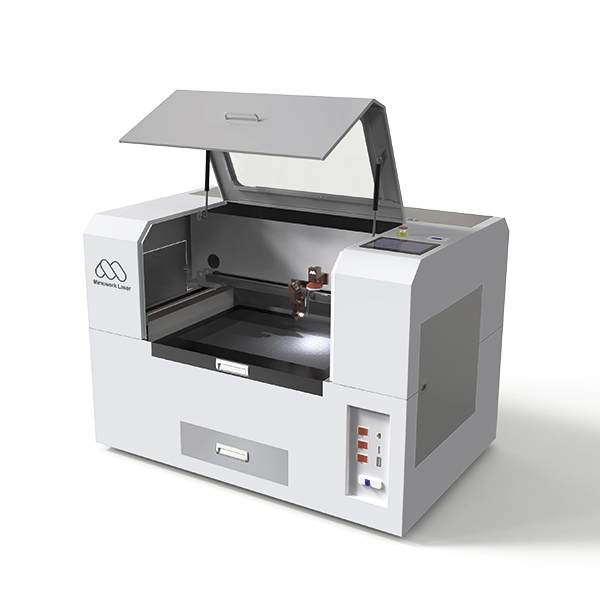

Working Table Size: 600mm * 400mm (23.6” * 15.7”)

Laser Power Options: 65W

Overview of Desktop Laser Cutter 60

The Desktop Model - Flatbed Laser Cutter 60 boasts a compact design that effectively reduces the spatial demands within your room. It conveniently sits atop a table, presenting itself as an ideal entry-level choice for startups engaged in the creation of small custom products, such as acrylic awards, decorations, and jewelry.

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 130

The Flatbed Laser Cutter 130 is the most popular choice for acrylic cutting. Its pass-through working table design enables you to cut the large size of acrylic sheets longer than the working area. Moreover, it offers versatility by equipping with laser tubes of any power rating to meet the needs for cutting acrylic with different thicknesses.

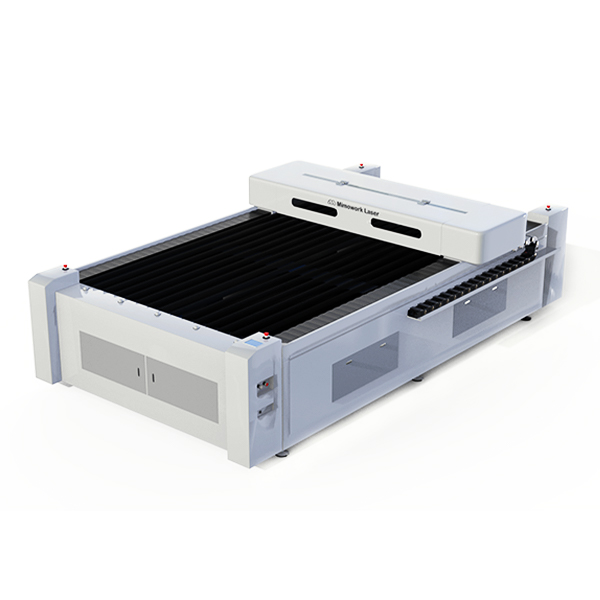

Working Table Size: 1300mm * 2500mm (51.2” * 98.4”)

Laser Power Options: 150W/300W/500W

Overview of Flatbed Laser Cutter 130L

The large-scale Flatbed Laser Cutter 130L is well-suited for cutting sizable acrylic sheets, including the frequently utilized 4ft x 8ft boards available in the market. This machine is specifically tailored to accommodate larger projects such as outdoor advertising signage, indoor partitions, and certain protective equipment. As a result, it stands out as a preferred option in industries such as advertising and furniture manufacturing.

▶ Operation Guide: How to Laser Cut Acrylic?

Depending on the CNC system and precise machine components, the acrylic laser cutting machine is automatic and easy to operate. You just need to upload the design file to the computer, and set the parameters according to material features and cutting requirements. The rest will be left to the laser. It's time to free your hands and activate creativity and imagination in mind.

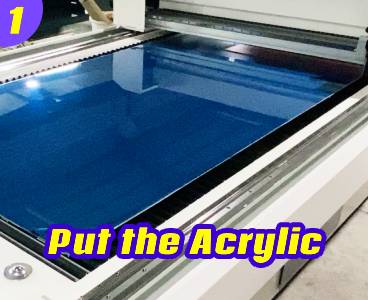

Step 1. prepare machine and acrylic

Acrylic Preparation: keep the acrylic flat and clean on the working table, and better to test using scrap before real laser cutting.

Laser Machine: determine the acrylic size, cutting pattern size, and acrylic thickness, to choose suitable machine.

▶

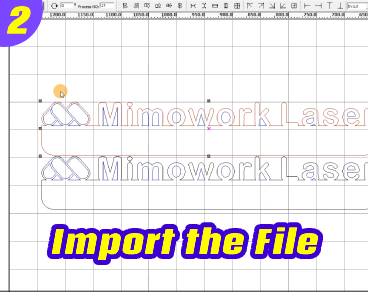

Step 2. set software

Design File: import the cutting file to the software.

Laser Setting: Talk to our laser expert to get general cutting parameters. But various materials have different thicknesses, purity, and density, so testing before is the best choice.

▶

Step 3. laser cut acrylic

Start Laser Cutting: The laser will automatically cut the pattern according to the given path. Remember to open the ventilation to clear away the fume, and turn down the air blowing to ensure the edge is smooth.

Video Tutorial: Laser Cutting & Engraving Acrylic

▶ How to Choose Laser Cutter?

There are a few considerations when choosing a suitable acrylic laser cutter for your project. Firstly you need to know the material information like thickness, size, and features. And Determine the cutting or engraving requirements like precision, engraving resolution, cutting efficiency, pattern size, etc. Next, if you have special requirements for non-fume production, equipping a fume extractor is available. Furthermore, you need to consider your budget and the machine price. We suggest you choose a professional laser machine supplier to get cost-effective cost, thorough service, and reliable production technology.

You Need To Consider

> What information you need to provide?

> Our contact information

> Acrylic laser cutting machine cost

> Whether choose laser machine options

▶ Using the Machine

> How thick of acrylic can laser cut?

The thickness of acrylic that a CO2 laser can cut depends on the specific power of the laser and the characteristics of the laser cutting system. In general, CO2 lasers are capable of cutting acrylic sheets with varying thicknesses up to 30mm. Additionally, factors such as the focus of the laser beam, the quality of optics, and the specific design of the laser cutter can impact the cutting performance.

Before attempting to cut thicker acrylic sheets, it's advisable to check the specifications provided by the manufacturer of your CO2 laser cutter. Conducting tests on scrap pieces of acrylic with various thicknesses can help determine the optimal settings for your specific machine.

Challenge: Laser Cutting 21mm Thick Acrylic

> How to avoid laser cutting acrylic fumes?

> Tutorial of acrylic laser cutter

How to find focus of laser lens?

How to install laser tube?

How to clean laser lens?

Learn More about Laser Cutting Acrylic,

Click here to talk with us!

CO2 Laser Cutter for Acrylic is an intelligent and automatic machine and a reliable partner in working and life. Different from other traditional mechanical processing, laser cutters make use of the digital control system to control the cutting path and cutting precision. And the stable machine structure and components guarantee smooth operation.

Any confusion or questions for the acrylic laser cutter, just inquire us at any time

Post time: Dec-11-2023