Can You Laser Cut Carbon Fiber?

7 Materials Not to Touch with a CO₂ Laser

Intro

CO₂ laser machines have become one of the most popular tools for cutting and engraving a wide range of materials, from acrylic and wood to leather and paper. Their precision, speed, and versatility make them a favorite in both industrial and creative fields. However, not every material is safe to use with a CO₂ laser. Some materials—like carbon fiber or PVC—can release toxic fumes or even damage your laser system. Knowing which CO₂ laser materials to avoid is essential for safety, machine longevity, and high-quality results.

7 Materials You Should Never Cut with a CO₂ Laser Cutter

1. Carbon Fiber

At first glance, carbon fiber might seem like a strong and lightweight material perfect for laser cutting. However, cutting carbon fiber with a CO₂ laser is not recommended. The reason lies in its composition — carbon fibers are bound with epoxy resin, which burns and releases harmful fumes when exposed to laser heat.

In addition, the intense energy from a CO₂ laser can damage the fibers, leaving rough, frayed edges and burnt spots instead of clean cuts. For projects that require carbon fiber processing, it’s best to use mechanical cutting or fiber laser technology specifically designed for composite materials.

2. PVC (Polyvinyl Chloride)

PVC is one of the most dangerous materials to use with a CO₂ laser. When heated or cut, PVC releases chlorine gas, which is highly toxic to humans and corrosive to your laser’s internal components. The fumes can quickly damage mirrors, lenses, and electronics inside the machine, leading to costly repairs or complete failure.

Even small tests on PVC sheets can leave long-term damage and health risks. If you need to process plastic with a CO₂ laser, choose acrylic (PMMA) instead—it’s safe, cuts cleanly, and produces no toxic gas.

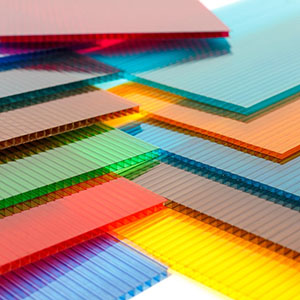

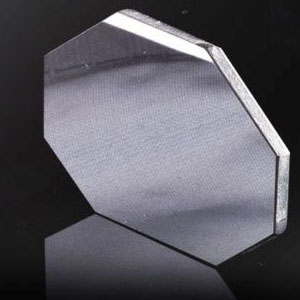

3. Polycarbonate (PC)

Polycarbonate is often mistaken for a laser-friendly plastic, but it reacts poorly under CO₂ laser heat. Instead of vaporizing cleanly, polycarbonate discolors, burns, and melts, leaving charred edges and producing smoke that can cloud your optics.

The material also absorbs too much infrared energy, making it nearly impossible to achieve a clean cut. If you need transparent plastic for laser cutting, cast acrylic is the best and safest alternative—delivering smooth, polished edges every time.

4. ABS Plastic

ABS plastic is super common—you’ll find it in 3D prints, toys, and everyday products. But when it comes to laser cutting, ABS and CO₂ lasers just don’t mix. The material doesn’t vaporize like acrylic; instead, it melts and gives off thick, sticky smoke that can coat your machine’s lens and mirrors.

Even worse, burning ABS releases toxic fumes that are unsafe to breathe and can damage your laser over time. If you’re working on a project that involves plastics, stick with acrylic or Delrin (POM)—they cut beautifully with a CO₂ laser and leave clean, smooth edges.

5. Fiberglass

Fiberglass might look tough enough for laser cutting, but it’s definitely not a good match for a CO₂ laser. This material is made from tiny glass fibers and resin, and when the laser hits it, the resin burns instead of cutting cleanly. That creates toxic smoke and messy, dark edges that ruin your project—and it’s not great for your laser, either.

Because the glass fibers can reflect or scatter the laser beam, you’ll also get uneven cuts or even optical damage. If you need to cut something similar, go for safer CO₂ laser materials like acrylic or plywood instead.

6. HDPE (High-Density Polyethylene)

HDPE is another plastic that doesn’t get along well with a CO₂ laser cutter. When the laser hits HDPE, it melts and warps easily instead of cutting cleanly. You’ll often end up with rough, uneven edges and a burned smell that lingers in your workspace.

What’s worse, molten HDPE can ignite and drip, posing a real fire hazard. So if you’re planning a laser cutting project, skip HDPE and use laser-safe materials like acrylic, plywood, or cardboard instead—they deliver much cleaner, safer results.

7. Coated or Reflective Metals

You might be tempted to try engraving metal with a CO₂ laser, but not all metals are safe or suitable. Coated or reflective surfaces, such as chrome or polished aluminum, can reflect the laser beam back into your machine, damaging the laser tube or optics.

A standard CO₂ laser also doesn’t have the right wavelength to cut through metal efficiently—it only marks certain coated types at best. If you want to work with metals, use a fiber laser machine instead; it’s designed specifically for metal engraving and cutting.

Not Sure If Your Material Is Safe for a CO₂ Laser Cutter?

Safety Tips & Recommended Materials

Before you start any laser cutting project, always double-check whether your material is CO₂ laser safe.

Stick to reliable options like acrylic, wood, paper, leather, fabric, and rubber—these materials cut beautifully and don’t release toxic fumes. Avoid unknown plastics or composites unless you’ve confirmed they’re safe for CO₂ laser use.

Keeping your work area ventilated and using an exhaust system will also protect you from fumes and extend your machine’s life.

FAQs About CO₂ Laser Materials

Not safely. The resin in carbon fiber releases toxic fumes when heated, and it can damage your CO₂ laser optics.

Acrylic (PMMA) is the best choice. It cuts cleanly, produces no toxic gas, and gives polished edges.

Using unsafe materials can damage your CO₂ laser machine and release toxic fumes. The residue may cloud your optics or even corrode metal parts inside your laser system. Always verify material safety first.

Recommended CO2 Laser Machines

|

Working Area (W *L) |

1300mm * 900mm (51.2” * 35.4 ”) |

|

Max Speed |

1~400mm/s |

|

Laser Power |

100W/150W/300W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Marx Speed | 1~400mm/s |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Working Area (W*L) |

600mm * 400mm (23.6” * 15.7”) |

|

Max Speed |

1~400mm/s |

|

Laser Power |

60W |

|

Laser Source |

CO2 Glass Laser Tube |

Want to learn more about MimoWork’s CO₂ laser machines?

Post time: Oct-15-2025