The Future of Precision Cutting in Textile Industry

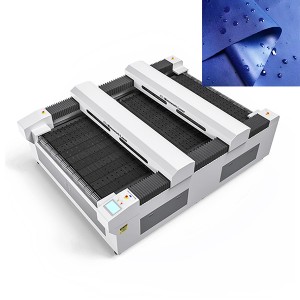

Laser cutter machine for fabric

Laser cut fabric is a new cutting method that has gained popularity in the textile industry. This cutting technique uses a laser beam to cut fabrics with precision and accuracy, leaving behind clean edges without fraying. In this article, we will discuss what laser cut fabric is, its benefits, and why a fabric laser cutter is the best tool for achieving precise and high-quality results.

What is Laser Cut Fabric?

Fabric laser cut is a cutting technique that uses a high-powered laser beam to cut fabric with incredible accuracy and precision. The laser beam vaporizes the fabric as it cuts, leaving behind a clean and neat edge without any fraying. This method is ideal for cutting delicate and intricate designs, as it allows for highly accurate and precise cuts.

Benefits of Laser Cut Fabric

• Highly accurate and precise cuts is allowed

Like we have mentioned above, unlike traditional cutting methods, fabric laser cutting does not involve any physical contact with the fabric, which means that there is no risk of the fabric being stretched, distorted or frayed during the cutting process. This is especially important when working with delicate and intricate designs, as even a small mistake can ruin the entire piece.

• Highly efficient and time-saving method of cutting

Unlike traditional cutting methods, laser cutting can cut multiple layers of fabric at once, which means that it is an ideal method for mass production. This not only saves time but also reduces material waste, making it an environmentally friendly option.

Why a Fabric Laser Cutter is the Best Tool for Laser Cut Fabric

While laser cutting fabric can be done using a range of laser cutters for fabric, a fabric laser cutter is the best tool for cutting fabric. It is designed specifically for cutting fabric and is equipped with features that are tailored to the unique properties of fabric.

• No damage or fraying

One of the key features of a fabric laser cutter is that it allows for highly accurate and precise cuts. This is achieved through the use of a highly-focused laser beam that is able to cut through even the most delicate fabrics without causing any damage or fraying. Additionally, laser cutters for fabric are equipped with software that allows for highly accurate and precise control of the cutting process, ensuring that the fabric is cut to the exact specifications of the design.

• Incredibly versatile

It can be used to cut a wide range of fabrics, including delicate and intricate fabrics such as lace, silk, and chiffon. Additionally, fabric laser cutting machine can be used to cut fabrics into a wide range of shapes and sizes, making them an ideal tool for creating a range of designs.

In conclusion

Laser cut fabric is an innovative cutting method that is gaining popularity in the textile industry. It offers a range of benefits, including highly accurate and precise cuts, efficient mass production, and reduced material waste. To achieve the best results, it is important to use a fabric laser cutter, which is designed specifically for cutting fabric and is equipped with features that are tailored to the unique properties of fabric. With the use of a fabric laser cutter machine, the possibilities for creating intricate and beautiful designs are endless, making it an essential tool for any textile professional or enthusiast.

Recommended Laser cutter machine for fabric

Want to invest in Laser cutting on fabrics?

Post time: Mar-01-2023