How to Cut Velcro Fabric?

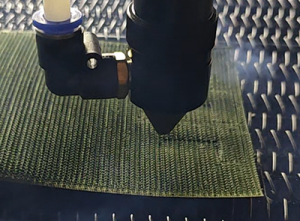

Laser cutting Velcro fabric offers a precise and efficient method for creating custom shapes and sizes. By using a high-powered laser beam, the fabric is cut cleanly, ensuring no fraying or unraveling.

This technique is ideal for applications requiring intricate designs and high production efficiency.

Laser Cut Velcro

What Is Velcro Fabric?

Velcro fabric is a hook-and-loop fastening material widely used in apparel, medical straps, sports gear, packaging, and industrial applications.

Before learning how to cut Velcro fabric, it helps to understand its structure:

• Hook side: stiff, rigid hooks

• Loop side: soft fabric surface

Different types include sew-on Velcro, adhesive Velcro, elastic loop fabric, and fire-retardant Velcro. These variations influence the Velcro fabric cutting method you choose.

Why Cutting Velcro Fabric Can Be Tricky

If you’ve ever tried cutting Velcro with scissors, you know the frustration. The edges fray, making it difficult to attach securely. Choosing the right cutting method is the key to smooth, durable results.

▶ Traditional Cutting Methods

Scissors

Cutting Velcro by Scissor

Scissors are the simplest and most accessible way to cut Velcro, but they are not always the most effective. Standard household scissors tend to leave rough, frayed edges that weaken the overall hold of the Velcro. This fraying can also make it harder to stitch or glue the material securely onto fabric, wood, or other surfaces. For small, occasional projects, scissors may be acceptable, but for clean results and long-term durability, they often fall short.

Velcro Cutter

Cutting Velcro by Velcro Cutter

A Velcro cutter is a specialized tool designed specifically for this material. Unlike scissors, it uses sharp, well-aligned blades to create smooth, sealed edges that won’t unravel. This makes it much easier to attach Velcro securely with stitching, adhesive, or even industrial fastening methods. Velcro cutters are lightweight, easy to handle, and perfect for craft makers, workshops, or anyone who frequently works with Velcro. If you need precision and consistency without investing in heavy machinery, a Velcro cutter is a reliable choice.

▶ Modern Solution — Laser Cut Velcro

Laser Cutting Machine

One of the most advanced methods today is to laser cut Velcro. Instead of relying on blades, a high-powered laser beam precisely melts through the fabric, creating smooth, sealed edges that will not fray over time. This technology not only improves durability but also allows for highly detailed and complex shapes that are difficult—if not impossible—to achieve with traditional tools.

Another key advantage of laser cutting is its digital precision. By using a computer design file (CAD), the laser follows the pattern exactly, ensuring every cut is identical. This makes laser cut Velcro an excellent choice for industries such as sportswear, medical devices, aerospace, and custom manufacturing where consistency and accuracy are essential.

While the upfront cost of laser cutting equipment can be high, the long-term benefits—minimal waste, reduced labor, and premium results—make it a worthwhile investment for workshops and factories that process Velcro regularly.

How to Cut Velcro Fabric: Step-by-Step Guide

1、Place fabric flat on table

2、Use low power + high speed

3、Test cut first

4、Use single or multi-pass depending on thickness

5、Clean residue after cutting

Applications of Laser-Cut Velcro Fabric

Laser-cut Velcro is widely used in:

• Medical straps and braces

• Sports equipment

• Wearable electronics

• Automotive interiors

• Packaging straps

• Apparel and accessories

• Industrial fastening components

FAQs for Laser Cutting Velcro Fabric

Laser cutting Velcro fabric uses a focused CO₂ laser beam to cut cleanly through the material, melting and sealing edges at the same time for smooth, durable results.

Yes, the heat from the laser seals the cut edges instantly, preventing fraying and keeping the Velcro fabric neat and strong.

Laser cutting can achieve micron-level precision, allowing intricate patterns, curves, and detailed shapes without damaging the material.

Yes, automated laser systems are safe, efficient, and ideal for continuous operation in industrial production lines.

Absolutely, laser cutting enables tailor-made shapes, logos, and patterns, offering maximum flexibility for creative and industrial projects.

By sealing edges and avoiding fiber damage, laser cutting enhances the long-term durability and fastening reliability of Velcro products.

Learn More about How to Laser Cut Velcro Fabric

Recommended Fabric Laser Cutter

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Software | Offline Software |

| Laser Power | 150W/300W/450W |

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Working Area (W * L) | 1800mm * 1000mm (70.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

Related Materials of Laser Cutting

Conclusion

Learning how to cut Velcro fabric properly ensures clean edges, consistent shapes, and high productivity. While scissors and rotary blades work for simple tasks, laser cutting Velcro provides the best edge quality, speed, and precision—making it the most reliable method for both small and large-scale production.

Learn More Information about Laser Velcro Cutter Machine?

Last Updated: November 20, 2025

Post time: Apr-20-2023