Sustainable Fabric Cutting Exploring the Environmental Impact of Laser Cutting Fabric

Environmental Impact of Laser Cutting Fabric

Laser cutting fabric is a relatively new technology that has gained popularity in recent years due to its precision, speed, and versatility. However, as with any manufacturing process, there are environmental impacts to consider. In this article, we will explore the sustainability of laser cutting fabric and examine its potential impact on the environment.

Energy Use

Laser cutting for fabrics requires a significant amount of energy to operate. The lasers used in the cutting process consume a large amount of electricity, which contributes to greenhouse gas emissions and global warming. However, advances in technology have led to the development of more energy-efficient lasers that consume less energy and produce fewer emissions.

Waste Reduction

One of the most significant benefits of laser fabric cutter is its ability to reduce waste. Traditional fabric cutting methods often result in significant amounts of fabric waste due to the imprecision of manual cutting techniques. Laser cutting, on the other hand, allows for precise cuts, which minimizes waste and saves fabric.

Chemical Use

Laser cutting for fabrics does not require the use of chemicals, which can be harmful to the environment and human health. Traditional fabric cutting methods often involve the use of chemicals such as dyes, bleaches, and finishing agents, which can have negative environmental impacts. Laser cutting eliminates the need for these chemicals, making it a more sustainable alternative.

Water Use

Laser cutting fabric does not require the use of water, which can be a scarce resource in some areas. Traditional fabric cutting methods often involve washing and dyeing the fabric, which can consume large amounts of water. Laser cutting eliminates the need for these processes, making it a more sustainable alternative.

Air Pollution

Laser fabric cutter can produce air pollution in the form of fumes and emissions from the laser cutting process. These emissions can be harmful to human health and contribute to air pollution. However, modern laser cutting machines are equipped with air filtration systems that remove these harmful emissions from the air, making the process more sustainable.

Equipment Lifespan

Laser cutting machines have a longer lifespan than traditional fabric cutting equipment. They are more durable and require less maintenance, which reduces the need for replacement and disposal. This makes laser cutting a more sustainable alternative in the long run.

Material Compatibility

Laser cutting is compatible with a wide range of materials, including natural and synthetic fabrics, leather, and foam. This versatility makes it a more sustainable alternative to traditional cutting methods that may require multiple machines for different materials.

Recycling and Upcycling

Laser cutting can facilitate recycling and upcycling of fabric waste. The precise cuts produced by laser cutting make it easier to recycle and upcycle fabric scraps into new products, reducing the amount of waste sent to landfills.

In Conclusion

Fabric laser cutter has the potential to be a more sustainable alternative to traditional cutting methods. While it does require a significant amount of energy, it can significantly reduce fabric waste and eliminate the need for harmful chemicals and excessive water use. Modern laser cutting machines are equipped with air filtration systems that reduce air pollution, and their longer lifespan makes them a more sustainable option in the long run. Additionally, laser cutting can facilitate recycling and upcycling of fabric waste, further reducing environmental impact. Overall, while there are still environmental impacts to consider, laser cutting fabric has the potential to be a more sustainable alternative to traditional cutting methods.

Video Display | Glance for Fabric Laser Cutting

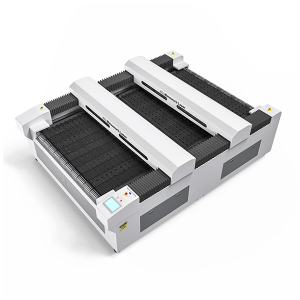

Recommended Fabric laser cutter

Any questions about the operation of Fabric Laser Cutter?

Post time: Apr-14-2023