Top Considerations for Laser Cutting Plywood

A Guide of Wood Laser Engraving

Laser cut plywood offers unmatched precision and versatility, making it ideal for everything from crafts to large-scale projects. To achieve clean edges and avoid damage, it’s essential to understand the right settings, material preparation, and maintenance tips. This guide shares key considerations to help you get the best results when using a laser wood cutting machine on plywood.

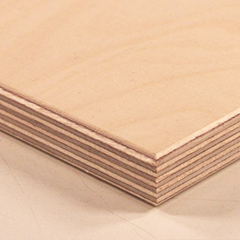

Choosing the Right Plywood

Types of Plywood for Laser Cutting

Choosing the right plywood is essential for achieving clean and precise results with laser cut plywood projects. Different plywood types offer unique advantages, and selecting the right one ensures better performance and finish quality.

Laser Cut Plywood

Birch Plywood

Fine, even grain with minimal voids, excellent for detailed engraving and intricate designs.

Poplar Plywood

Lightweight, easy to cut, great for decorative panels and large designs.

Veneer-Faced Plywood

Decorative wood veneer surface for premium projects, offers a natural wood finish.

Specialty Thin Plywood

Ultra-thin sheets for model making, crafts, and projects requiring delicate cuts.

MDF-Core Plywood

Smooth cutting edges and consistent density, perfect for painted or laminated finishes.

Which Plywood Should I Choose Based on Laser Cutting Needs?

| Laser Cutting Use | Recommended Plywood Type | Notes |

|---|---|---|

| Fine Detailed Engraving | Birch | Smooth grain & minimal voids for crisp edges |

| Fast Cutting With Moderate Detail | Poplar | Lightweight and easy to cut for better efficiency |

| Large Area Cutting | MDF-Core | Consistent density for uniform cuts |

| High-Quality Edge Finish Required | Veneer-Faced | Decorative surface requires precise settings |

| Thin, Delicate Cuts | Specialty Thin | Ultra-thin for intricate models and crafts |

Baltic Birch Plywood

Plywood Thickness

The thickness of the plywood can also affect the quality of the wood laser cut. Thicker plywood requires higher laser power to cut through, which can cause the wood to burn or char. It is important to choose the right laser power and cutting speed for the thickness of the plywood.

Material Preparation Tips

Cutting Speed

The cutting speed is how quickly the laser moves across the plywood. Higher cutting speeds can increase productivity, but they can also decrease the quality of the cut. It is important to balance cutting speed with the desired cut quality.

Laser Power

The laser power determines how quickly the laser can cut through the plywood. Higher laser power can cut through thicker plywood more quickly than lower power, but it can also cause the wood to burn or char. It is important to choose the right laser power for the thickness of the plywood.

Laser Cutting Die Board Steps2

Laser Cutting Wood Die Board

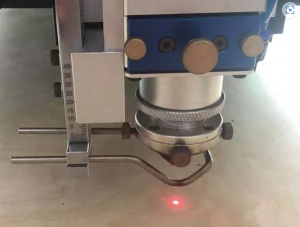

Focus Lens

The focus lens determines the size of the laser beam and the depth of the cut. A smaller beam size allows for more precise cuts, while a larger beam size can cut through thicker materials. It is essential to choose the correct focus lens for the thickness of the plywood.

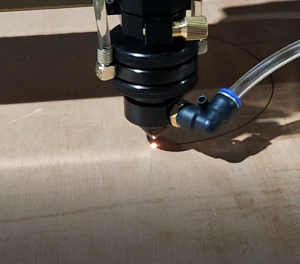

Air Assist

Air assist blows air onto the laser cutting plywood, which helps remove debris and prevents scorching or burning. It is especially important for cutting plywood because the wood can produce a lot of debris during cutting.

Air Assist

Cutting Direction

The direction in which the laser wood cutting machines the plywood can affect the quality of the cut. Cutting against the grain can cause the wood to splinter or tear, while cutting with the grain can produce a cleaner cut. It is important to consider the direction of the wood grain when designing the cut.

Laser Cutting Wood Die Doard 3

Design Considerations

When designing the laser cut, it is important to consider the thickness of the plywood, the intricacy of the design, and the type of joint used. Some designs may require additional supports or tabs to hold the plywood in place during cutting, while others may require special consideration for the type of joint used.

Common Issues & Troubleshooting

Reduce laser power or increase cutting speed; apply masking tape to protect the surface.

Increase laser power or reduce speed; make sure the focal point is correctly set.

Choose plywood with low moisture content and secure it firmly to the laser bed.

Use lower power with multiple passes, or adjust settings for cleaner cuts.

For laser cut plywood, choose birch, basswood, or maple with a smooth surface, low-resin glue, and minimal voids. Thin sheets suit engraving, while thicker sheets need more power.

In conclusion

Laser cutting on plywood can produce high-quality cuts with precision and speed. However, there are several important factors to consider when using laser cutting on plywood, including the type of plywood, the thickness of the material, the cutting speed and laser power, the focus lens, air assist, cutting direction, and design considerations. By taking these factors into account, you can achieve the best results with laser cutting on plywood.

Recommended Wood Laser Cutting machine

| Working Area (W *L) | 80mm * 80mm (3.15'' * 3.15'') |

| Laser Source | Fiber Laser |

| Laser Power | 20W |

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Laser Power | 100W/150W/300W |

| Working Area (W *L) | 1300mm * 2500mm (51” * 98.4”) |

| Laser Source | CO2 Glass Laser Tube |

| Laser Power | 150W/300W/450W |

Want to Invest in Wood Laser Machine?

Post time: Mar-17-2023