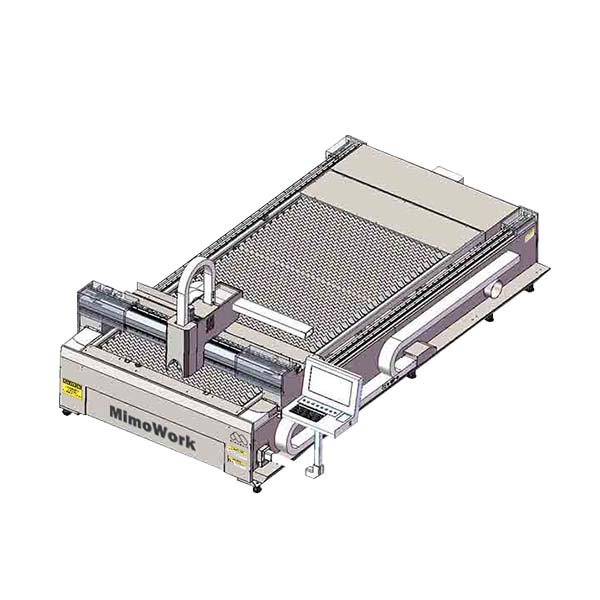

Flatbed Laser Cutter 250L

Advantages of Commercial Laser Cutter

Ultimate Large Fabric Cutter

◉ Wide applications in industries such as outdoor equipment, technical textile, home textile

◉ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Evolutionary visual recognition technology and powerful software provide higher quality and reliability for your business.

◉ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

◉ Advanced mechanical structure allows laser options and customized working table

Technical Data

| Working Area (W * L) | 2500mm * 3000mm (98.4’’ *118’’) |

| Max Material Width | 98.4’’ |

| Software | Offline Software |

| Laser Power | 150W/300W/450W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack and Pinion Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

(Upgrade for your industrial fabric laser cutting machine, textile laser cutter)

Ideal for Technical Textile Laser Cutting

Video Glance | How to Laser Cut Fabric Duct

Engraving, marking, and cutting can be realized in single process

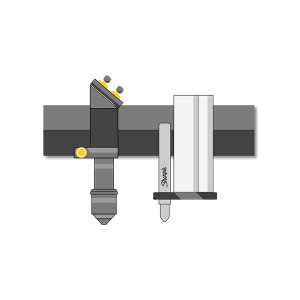

✔ High precision in cutting, marking, and perforating with fine laser beam

✔ Fewer material waste, no tool wear, better control of production costs

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Ensures a safe working environment during operation

Clean and smooth edge with thermal treatment

✔ Bringing about more economical and environment-friendly manufacturing process

✔ Customized working tables meet requirements for varieties of materials formats

✔ Quick response to market from samples to large-lot production

Your popular and wise manufacturing direction

✔ Smooth and lint-free edge through heat treatment

✔ High precision in cutting, marking, and perforating with fine laser beam

✔ Greatly saving cost in materials waste

The secret of exquisite pattern cutting

✔ Realize unattended cutting process, reduce manual workload

✔ High-quality value-added laser treatments like engraving, perforating, marking, etc Mimowork adaptable laser ability, suitable to cut diverse materials

✔ Customized tables meet requirements for varieties of materials formats

Common materials and applications

of Flatbed Laser Cutter 250L

Materials: Fabric, Leather, Nylon, Kevlar, Coated Fabric, Polyester, EVA, Foam, Industrial Materials, Synthetic Fabric, and other Non-metal Materials

Applications: Functional Garment, Carpet, Automotive interior, Car Seat, Airbags, Filters, Air Dispersion Ducts, Home Textile (Mattress, Curtains, Sofas, Armchairs, Textile Wallpaper), Outdoor (Parachutes, Tents, Sports Equipment)