Your Requirements = Our Specifications

Polartec Fabric Guide

Table of Contents:

Introduction of Polartec Fabric

Polartec fabric (Polartec fabrics) is a high-performance fleece material developed in the USA. Made from recycled polyester, it offers lightweight, warm, quick-drying and breathable properties.

The Polartec fabrics series includes various types like Classic (basic), Power Dry (moisture-wicking) and Wind Pro (windproof), widely used in outdoor apparel and gear.

Polartec fabric is renowned for its durability and eco-friendliness, making it a top choice for professional outdoor brands.

Polartec Fabric

Types of Polartec Fabric

Polartec Classic

Basic fleece fabric

Lightweight, breathable, and warm

Used in mid-layer garments

Polartec Power Dry

Moisture-wicking performance

Quick-drying and breathable

Ideal for base layers

Polartec Wind Pro

Wind-resistant fleece

4x more windproof than Classic

Suitable for outer layers

Polartec Thermal Pro

High-loft insulation

Extreme warmth-to-weight ratio

Used in cold-weather gear

Polartec Power Stretch

4-way stretch fabric

Form-fitting and flexible

Common in activewear

Polartec Alpha

Dynamic insulation

Regulates temperature during activity

Used in performance apparel

Polartec Delta

Advanced moisture management

Mesh-like structure for cooling

Designed for high-intensity activities

Polartec Neoshell

Waterproof and breathable

Soft-shell alternative

Used in outerwear

Why Choose Polartec?

Polartec® fabric is exceptionally well-suited for laser cutting, as its synthetic composition allows the fibers to melt and fuse under heat. This creates precisely sealed, non-fraying edges—ideal for intricate patterns, complex shapes, and fine detailing in apparel, outdoor gear, and crafts. The process not only ensures clean, durable finishes but also supports engraving for added texture, delivering precision and efficiency beyond traditional cutting methods.

Polartec Fabric vs Other Fabrics

Polartec vs. Traditional Fleece

| Feature | Polartec Fabric | Regular Fleece |

|---|---|---|

| Warmth | High warmth-to-weight ratio (varies by type) | Bulky, less efficient insulation |

| Breathability | Engineered for active use (e.g., Alpha, Power Dry) | Often traps heat and sweat |

| Moisture-Wicking | Advanced moisture management (e.g., Delta, Power Dry) | Absorbs moisture, dries slowly |

| Wind Resistance | Options like Wind Pro & NeoShell block wind | No inherent wind resistance |

| Durability | Resists pilling and wear | Prone to pilling over time |

| Eco-Friendliness | Many fabrics use recycled materials | Typically virgin polyester |

Polartec vs. Merino Wool

| Feature | Polartec Fabric | Merino Wool |

|---|---|---|

| Warmth | Consistent even when wet | Warm but loses insulation when damp |

| Moisture-Wicking | Faster drying (synthetic) | Natural moisture control |

| Odor Resistance | Good (some blends with silver ions) | Naturally anti-microbial |

| Durability | Highly durable, resists abrasion | Can shrink/weaken if mishandled |

| Weight | Lightweight options available | Heavier for similar warmth |

| Sustainability | Recycled options available | Natural but resource-intensive |

Now that you understand these fabric properties, precise laser cutting technology can perfectly showcase their performance advantages. The following video will introduce how to select the appropriate laser power for cutting.

Related Video:

Guide to the Best Laser Power for Cutting Fabrics

In this video, we can see that different laser cutting fabrics require different laser cutting powers and learn how to choose laser power for your material to achieve clean cuts and avoid scorch marks.

Recommended Polartec Laser Cutting Machines

We Tailor Customized Laser Solutions for Production

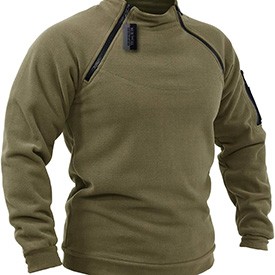

Typical Applications of Laser Cutting of Polartec Fabric

Apparel & Fashion

Performance Wear: Cutting intricate patterns for jackets, vests, and base layers.

Athletic & Outdoor Gear: Precise shaping for breathable panels in sportswear.

High-End Fashion: Custom designs with smooth, sealed edges to prevent unraveling.

Technical & Functional Textiles

Medical & Protective Clothing: Clean-cut edges for masks, gowns, and insulation layers.

Military & Tactical Gear: Laser-cut components for uniforms, gloves, and load-bearing equipment.

Accessories & Small-Scale Products

Gloves & Hats: Detailed cutting for ergonomic designs.

Bags & Packs: Seamless edges for lightweight, durable backpack components.

Industrial & Automotive Uses

Insulation Liners: Precision-cut thermal layers for automotive interiors.

Acoustic Panels: Custom-shaped sound-dampening materials.

Laser Cut Polartec Fabric: Process & Advantages

Polartec® fabrics (fleece, thermal, and technical textiles) are ideal for laser cutting due to their synthetic composition (typically polyester).

The laser’s heat melts the edges, creating a clean, sealed finish that prevents fraying—perfect for high-performance apparel and industrial applications.

The Process of Laser Cutting:

① Preparation

Ensure the fabric is flat and free of wrinkles.

Use a honeycomb or knife table for smooth laser bed support.

② Cutting

The laser melts the polyester fibers, creating a smooth, fused edge.

No additional hemming or stitching is needed for most applications.

③ Finishing

Minimal cleanup required (light brushing to remove soot if needed).

Some fabrics may have a slight "laser smell," which dissipates.

The Advantages of Laser Cutting:

① Sealed, Fray-Free Edges

The laser melts and fuses the synthetic fibers, creating smooth, durable edges that prevent unraveling and require no additional finishing.

② Digital Precision & Detail

Software-driven cutting ensures extreme accuracy and consistency, making it ideal for intricate patterns, technical apparel, and complex designs.

③ No Distortion, No Contact

As a non-contact process, the fabric remains flat and stable throughout cutting, eliminating stretching, warping, or shifting.

④Versatility Across Applications

Equally effective for functional items like insulation layers and acoustic panels, as well as decorative fashion elements and detailed crafts.

FAQS

Polartec® is a high-performance, synthetic fabric brand developed by Milliken & Company (and later owned by Polartec LLC).

It’s best known for its insulating, moisture-wicking, and breathable properties, making it a favorite in athletic wear, outdoor gear, military apparel, and technical textiles.

Polartec® microfleece technology is engineered around an air-permeable, lofted structure that forms the foundation of its advanced functionality. This intentionally lightweight design generates microscopic insulating air pockets which efficiently trap body heat, providing consistent warmth without bulk. Simultaneously, the open, breathable construction actively enables superior moisture management by wicking perspiration away from the skin and facilitating rapid evaporation, thereby promoting a continuous cooling effect and maintaining optimal comfort during activity.

To achieve optimal results when laser cutting Polartec (synthetic fleece), follow these key guidelines: use a CO₂ laser set to low power and high speed, and disable or minimize air assist to prevent fabric movement. Ensure precise focusing and always conduct a pre-test on a scrap piece to avoid melting or burning. For cutting, use vector mode to create clean, sealed edges; switch to raster mode for engraving textured patterns. Adequate ventilation is essential throughout the process.

Yes, Polartec® is generally more expensive than standard fleece due to its advanced performance features, durability, and brand reputation. However, its cost is justified for technical applications where quality matters.

Polartec® offers varying levels of water resistance depending on the specific fabric type, but it’s important to note that most Polartec fabrics are not fully waterproof—they’re designed for breathability and moisture management rather than complete waterproofing.

The warmest Polartec® fabric depends on your needs (weight, activity level, and conditions), but here are the top contenders ranked by insulation performance:

1. Polartec® High Loft (Warmest for Static Use)

Best for: Extreme cold, low activity (parkas, sleeping bags).

Why? Ultra-thick, brushed fibers trap maximum heat.

Key Feature: 25% warmer than traditional fleece, lightweight for its loft.

2. Polartec® Thermal Pro® (Balanced Warmth + Durability)

Best for: Versatile cold-weather gear (jackets, gloves, vests).

Why? Multi-layer loft resists compression, retains heat even when wet.

Key Feature: Recycled options available, durable with a soft finish.

3. Polartec® Alpha® (Active Warmth)

Best for: High-intensity cold-weather activities (skiing, military ops).

Why? Lightweight, breathable, and retains warmth when wet or sweaty.

Key Feature: Used in U.S. military ECWCS gear ("puffy" insulation alternative).

4. Polartec® Classic (Entry-Level Warmth)

Best for: Everyday fleece (mid-layers, blankets).

Why? Affordable but less lofty than High Loft or Thermal Pro.