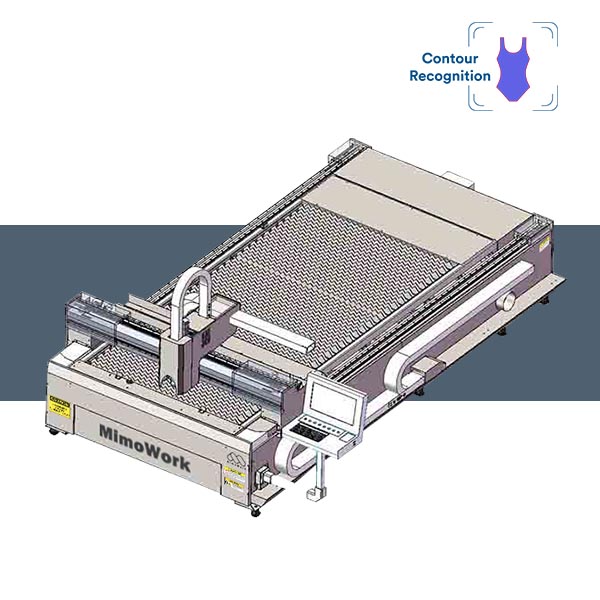

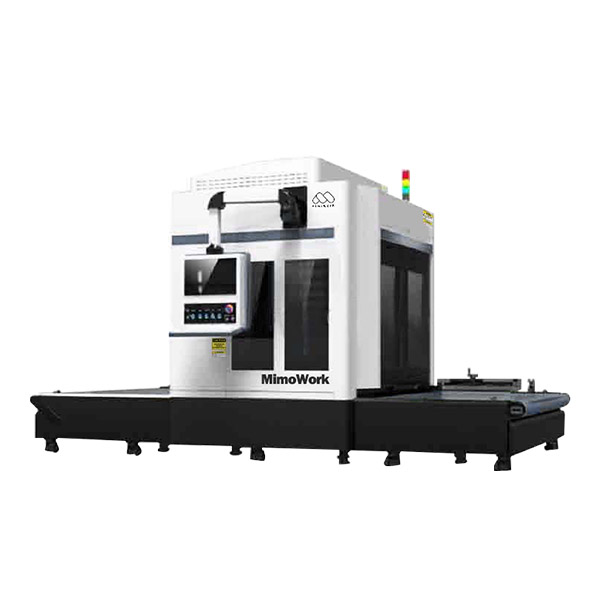

China Wholesale Laser Cut Mat Manufacturers Suppliers - Flatbed Laser Cutter 150L – MimoWork Laser

China Wholesale Laser Cut Mat Manufacturers Suppliers - Flatbed Laser Cutter 150L – MimoWork Laser Detail:

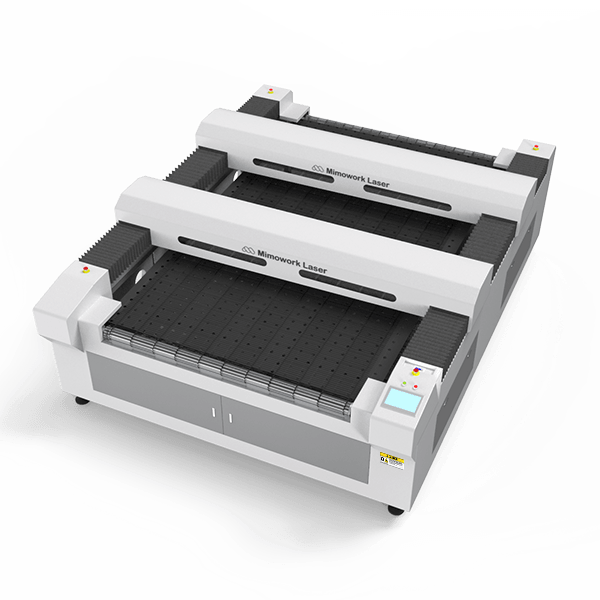

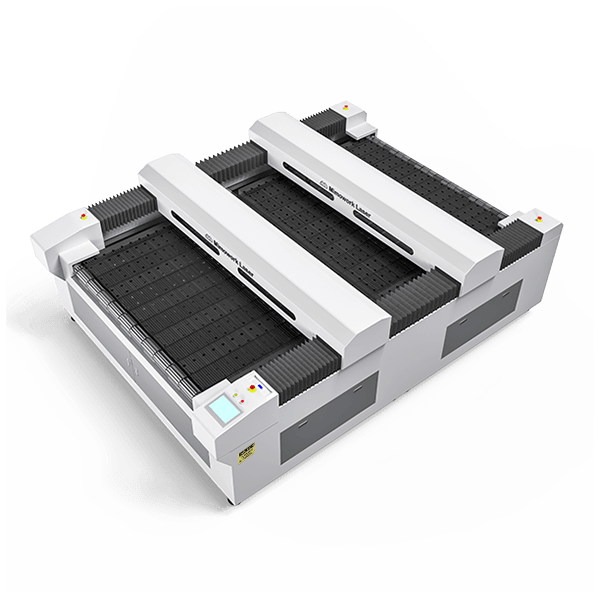

Large Format Laser Cutter for Wood & Acrylic

Technical Data

| Working Area (W * L) | 1500mm * 3000mm (59” *118”) |

| Software | Offline Software |

| Laser Power | 150W/300W/500W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

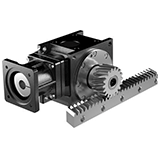

| Mechanical Control System | Rack & Pinion & Servo Motor Drive |

| Working Table | Knife Strip Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

(Superior Configurations & options for your large format laser cutter for acrylic, laser machine for wood)

Larger format, Wider applications

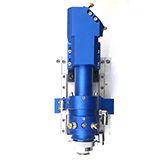

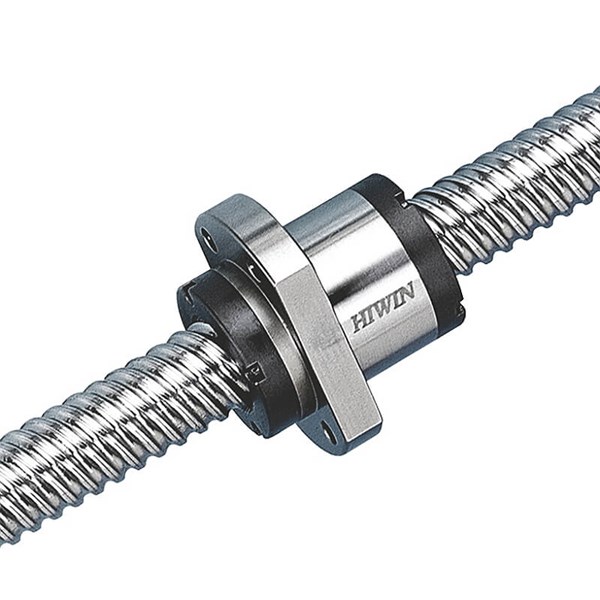

Rack & Pinion

A rack and pinion are a type of linear actuator that comprises a circular gear (the pinion) engaging a linear gear (the rack), which operates to translate rotational motion into linear motion. The rack and the pinion drive each other spontaneously. A rack and pinion drive can use both straight and helical gears. The rack and pinion ensure high speed and high precision laser cutting.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

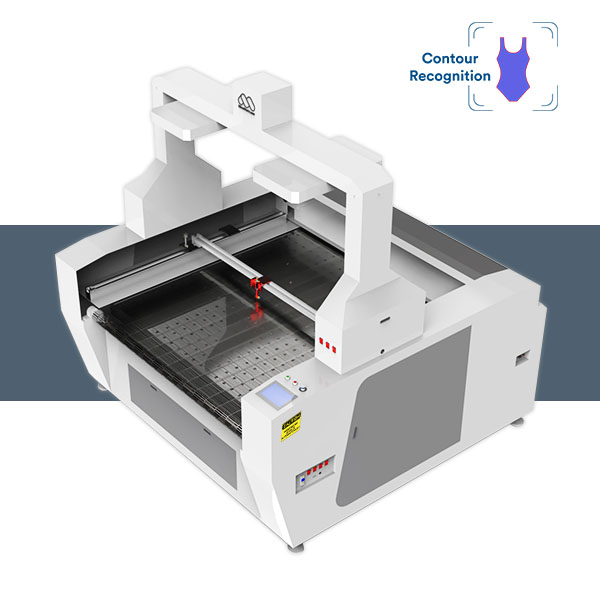

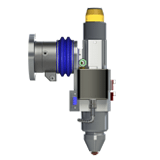

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thickness. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

Video Demonstration

<a href="https://www.mimowork.com/video-gallery/" title="Source from: Video Gallery” target=”_blank”>

Source from: Video Gallery

<a href="https://www.mimowork.com/material-testing/" title="Data from: Material Testing Base” target=”_blank”>

Data from: Material Testing Base

Can Thick Acrylic be Laser Cut?

Yes! The Flatbed Laser Cutter 150L is characterized by the high power, and has peerless ability for cutting thick materials like acrylic plate. Check the link to learn more acrylic laser cutting.

Further Details ⇩

◆ Sharp laser beam can cut through thick acrylic with even effect from surface to bottom

◆ Heat treatment laser cutting produces the smooth and crystal edge of flame-polished effect

◆ Any shapes and patterns are available for flexible laser cutting

Wondering if your material can be cut, and how to choose laser specifications?

Fields of Application

Laser Cutting for Your Industry

Wooden furniture

Laser Cutting for Your Industry

✔ Customized tables meet requirements for varieties of materials formats

✔ No limitation on shape, size, and pattern realizes flexible customization

✔ Significantly reduce the working time for orders in short delivery time

Common materials and applications

of Flatbed Laser Cutter 150L

Materials: Acrylic, Wood, MDF, Plywood, Plastic, and other Non-metal Material

Applications: Signs, Crafts, Ads Displays, Arts, Awards, Trophies, Gifts and many others

View more materials

View more applications

Learn acrylic laser cutter, laser wood cutting machine price

Add yourself to the list!

Product detail pictures:

Related Product Guide:

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for China Wholesale Laser Cut Mat Manufacturers Suppliers - Flatbed Laser Cutter 150L – MimoWork Laser , The product will supply to all over the world, such as: Islamabad, Amman, Venezuela, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer's trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.