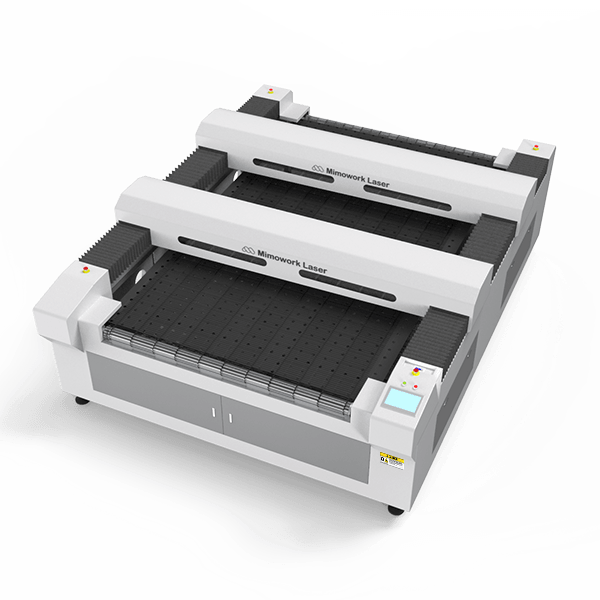

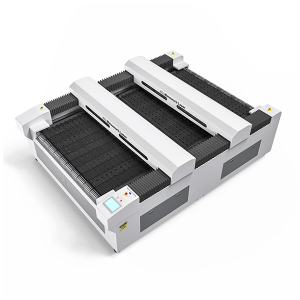

Flatbed Laser Cutter 150L

Large Format Laser Cutter for Wood & Acrylic

Technical Data

| Working Area (W * L) | 1500mm * 3000mm (59” *118”) |

| Software | Offline Software |

| Laser Power | 150W/300W/450W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Rack & Pinion & Servo Motor Drive |

| Working Table | Knife Strip Working Table |

| Max Speed | 1~600mm/s |

| Acceleration Speed | 1000~6000mm/s2 |

Can Thick Acrylic be Laser Cut?

Yes! The Flatbed Laser Cutter 150L is characterized by the high power, and has peerless ability for cutting thick materials like acrylic plate. Check the link to learn more acrylic laser cutting.

Further Details ⇩

◆ Sharp laser beam can cut through thick acrylic with even effect from surface to bottom

◆ Heat treatment laser cutting produces the smooth and crystal edge of flame-polished effect

◆ Any shapes and patterns are available for flexible laser cutting

Wondering if your material can be cut, and how to choose laser specifications?

Laser Cutting for Your Industry

✔ Customized tables meet requirements for varieties of materials formats

✔ No limitation on shape, size, and pattern realizes flexible customization

✔ Significantly reduce the working time for orders in short delivery time