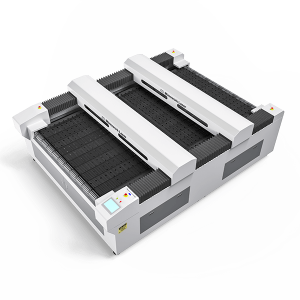

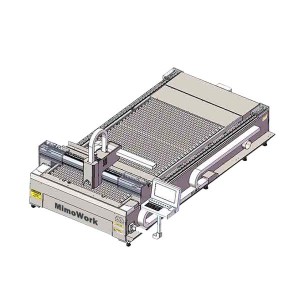

Plastic CO2 Laser Cutter and Engraver Machine

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for Plastic CO2 Laser Cutter and Engraver Machine, We have been searching ahead to even better cooperation with overseas buyers dependant on mutual benefits. Be sure to really feel totally free to speak to us for additional element!

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for custom laser cut jewelry, custom plastic cutting, laser cut plastic sheets, laser cut polyethylene, laser cut polypropylene, laser cutter for plastics, laser cutting plastic, laser engrave on plastic, laser engraver for plastic, laser engraving abs, Laser Engraving Plastic, laser etching on plastic, laser marking plastic, plastic laser engraver, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that “customer first” and committed to helping customers expand their business, so that they become the Big Boss !

Technical Data

|

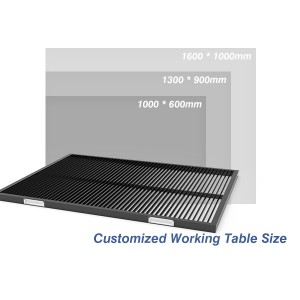

Working Area (W *L) |

1000mm * 600mm (39.3” * 23.6 ”) 1300mm * 900mm(51.2” * 35.4 ”) 1600mm * 1000mm(62.9” * 39.3 ”) <Customized Table Sizes Available> |

|

Software |

Offline Software |

|

Laser Power |

40W/60W/80W/100W |

|

Laser Source |

CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

|

Mechanical Control System |

Step Motor Belt Control |

|

Working Table |

Honey Comb Working Table or Knife Strip Working Table |

|

Max Speed |

1~400mm/s |

|

Acceleration Speed |

1000~4000mm/s2 |

|

Package Size |

1750mm * 1350mm * 1270mm |

|

Weight |

385kg |

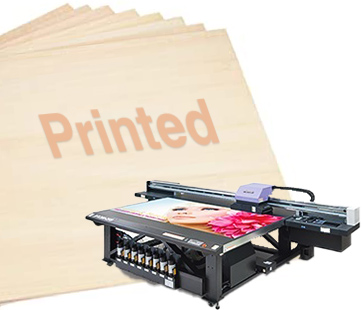

Upgrade with

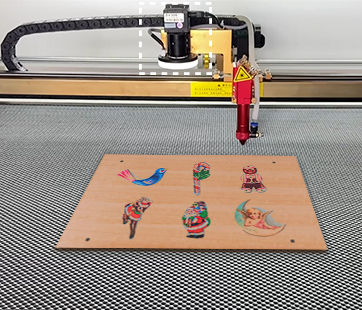

CCD Camera for your printed materials

CCD Camera can recognize and locate the printed pattern on the materials to assist the laser with accurate cutting. Signage, plaques, artwork and wood photo, branding logos, and even memorable gifts made of printed wood, printed acrylic and other printed materials can be easily processed.

Production Process

Step 1 .

>> Directly print your pattern on the wood board

Step 2 .

>> Collect your finished pieces

Other upgrade options for you to choose

Rotary Device

If you want to engrave on the cylindrical items, the rotary attachment can meet your needs and achieve a flexible and uniform dimensional effect with a more precise carved depth. Plugin the wire into the right places, the general Y-axis movement turns into the rotary direction, which solves the unevenness of engraved traces with the changeable distance from the laser spot to the round material’s surface on the plane.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

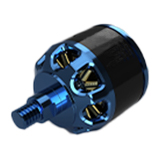

Brushless DC Motors

Brushless DC (direct current) motor can run at a high RPM (revolutions per minute). The stator of the DC motor provides a rotating magnetic field that drives the armature to rotate. Among all the motors, the brushless dc motor can provide the most powerful kinetic energy and drive the laser head to move at tremendous speed. MimoWork’s best CO2 laser engraving machine is equipped with a brushless motor and can reach a maximum engraving speed of 2000mm/s. The brushless dc motor is rarely seen in a CO2 laser cutting machine. This is because the speed of cutting through a material is limited by the thickness of the materials. On the contrary, you only need small power to carve graphics on your materials, A brushless motor equipped with the laser engraver will shorten your engraving time with greater accuracy.

Contact Us

Video Display

▷ Acrylic LED Display laser engraving

▷ Wood Decor Picture laser engraving

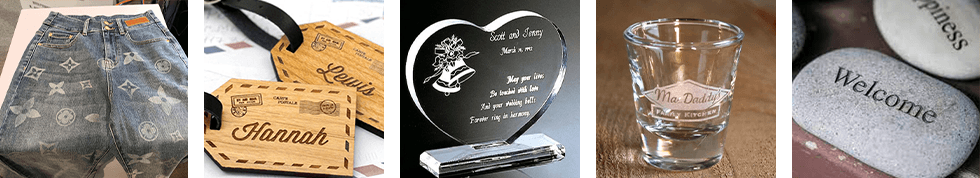

Samples of laser engraving

Leather, Plastic,

Paper, Metal, Laminate

Related Laser Machine

Fiber Laser Marking Machine

• Optional portable design

• Laser engraving & marking for metal and non-metal materials

Handheld Fiber Laser Marking Machine

• Table-top and handheld machine

• Rechargeable and user-friendly for engraving & marking

MimoWork Laser can meet you !

Professional and affordable laser machine

We’ve designed laser systems for dozens of clients

Add yourself to the list!

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our enterprise to the long-term to produce together with clients for mutual reciprocity and mutual profit for OEM China China Leather Belt Flatbed Cutter EVA Slipper Leather Cloth Price in India Cutting Machine, We have been searching ahead to even better cooperation with overseas buyers dependant on mutual benefits. Be sure to really feel totally free to speak to us for additional element!

Laser Cutting Plastic

Professional Laser Cutting Solution for Plastic

Benefitting from the premium laser performance and compatibility between the laser wavelength and plastic absorbance, the laser machine stands out in the traditional mechanical technics with higher speed and more excellent quality. Featured the non-contact and forceless processing, plastic items can be turned into a smooth edge and brilliant surface without stress damage. Just because of that and inherent powerful energy, laser cutting becomes the ideal method in plastic customized prototype making and volume manufacturing.

Laser cutting can meet varied plastics production with different properties, sizes, and shapes. Supported by the pass-through design and customized working tables from MimoWork, you can cut and engrave on the plastic without the limit of material formats. Besides Plastic Laser Cutter, UV Laser Marking Machine and Fiber Laser Marking Machine help to realize the plastic marking, especially for the identification of the electronic components and precise instruments.

Laser Processing for Plastic

1. Laser Cutting Plastic

Ultra-speed and the sharp laser beam can cut through the plastic instantly. Flexible movement with an X-Y axis structure helps laser cutting in all directions without shapes limitation. Internal cut and curve cut can be easily realized below one laser head.

2. Laser Engraving on plastic

A raster image can be laser engraved on the plastic. Changing laser power and fine laser beam build up the different engraved depths to present lively visual effects.

3. Laser Marking on plastic

Only with the lower laser power, the fiber laser machine can etch and mark on the plastic with permanent and clear identification. You can find the fine score on some electronic parts, tags, business cards, PCB.

Material information of Laser Cutting Polyester

Plastic has been permeated into all-around applications from daily items, commodity rack, and packing, to medical storer and precise electronic parts. Just since super performance like heat-resistance, anti-chemical, lightness, and flexible-plasticity, the demands for output and quality are increasingly growing. To meet that, laser cutting technology is ever-developing to adapt to the production of plastic in varied materials, shapes, and sizes. Due to the compatibility between the laser wavelength and plastic absorbance, the laser cutter shows technology versatility of cutting, engraving, and marking on the plastic.

The CO2 laser machine can help with plastic cutting and engraving easily to result in flawless finishing. Fiber laser and UV laser are playing important roles in plastic marking, like identification, logo, code, number on the plastic.

Common Materials of Plastic:

• ABS (acrylonitrile butadiene styrene)

• PMMA (Polymethylmethacrylate)

• Delrin (POM, acetal)

• PA (Polyamide)

• PC (Polycarbonate)

• PE (Polyethylene)

• PES (Polyester)

• PET (polyethylene terephthalate)

• PP (Polypropylene)

• PSU (Polyarylsulfone)

• PEEK (Polyether ketone)

• PI (Polyimide)

• PS (Polystyrene)