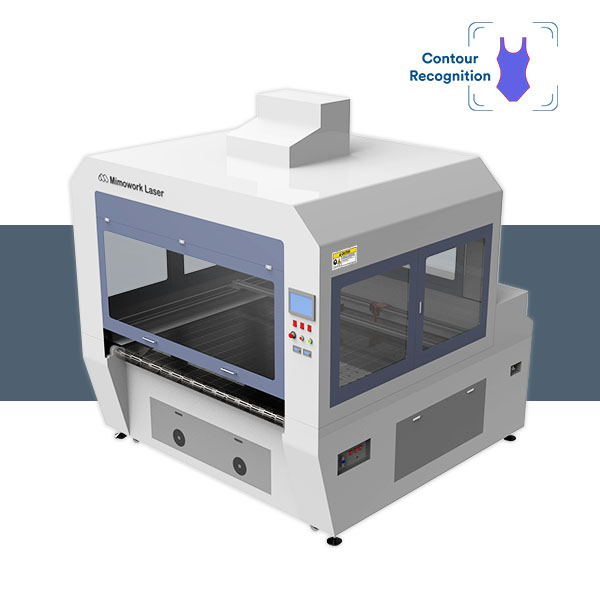

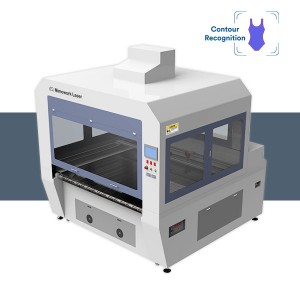

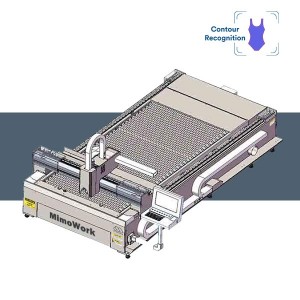

Contour Laser Cutter-Fully Enclosed

Technical Data

| Working Area (W *L) | 1800mm * 1300mm (70.87’’ * 51.18’’) |

| Max Material Width | 1800mm ( 70.87’’ ) |

| Laser Power | 100W/ 130W/ 150W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Automatic Fabric Cutting Machine for Sublimated Textiles

MimoWork Laser cares about your working safety

◼ Wide applications in industries such as digital printing, composite materials, clothing & home textiles

◼ Flexible and fast MimoWork laser cutting technology helps your products to quickly respond to market needs

◼ Evolutionary visual recognition technology and powerful software provide higher quality and reliability for your business.

◼ Automatic feeding allows unattended operation which saves your labor cost, lower rejection rate (optional)

D&R for flexible fabrics(sublimation banner, sportswear)

Independent Dual Heads - Option

MimoWork is committed to offer customized laser solution

for your specific demands

Video Demo of Enclosed Contour Laser Cutter

Find more videos about our sublimation laser cutters at our Video Gallery

Your popular and wise manufacturing direction

✔ High cutting quality, accurate pattern recognition, and fast production

✔ Meeting the needs of small-patch production for local sports team

✔ No need for cutting file

Your popular and wise manufacturing direction

✔ Significantly reduce the working time for orders in short delivery time

✔ The actual position and dimensions of the the work piece can be recognized exactly

✔ No material distortion thanks to the stress-free material feed and contact-less cutting

✔ Ideal cutter for making exhibition stands, banners, display systems, or visual protection

of Contour Laser Cutter-Fully Enclosed

Materials: Polyester Fabric, Spandex, Cotton, Silk, Printed Velvet, Film and other Sublimation Materials

Application: Rally Pennants, Banner, Billboard, Teardrop Flag, Leggings, Sportswear, Uniforms, Swimwear

The Newest Update about camera laser cutter

Super Camera Laser Cutter for Sportswear

✦ Updated Dual-Y-Axis Laser Heads

✦ 0 Delay Time - Continuous Processing

✦ High Automation - Less Labors

The sublimation fabric laser cutter is equipped with HD camera and extended collection table, that is more efficient and convenient for the whole laser cutting sportswear or other sublimation fabrics. We updated the dual laser heads into Dual-Y-Axis, which is more suitable for laser cutting sportswear, and further enhances cutting efficiency without any interference or delay.