Foil Galvo Laser Machine for kiss cutting

We’re going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Foil Galvo Laser Machine for kiss cutting, If possible, remember to ship your requirements with a detailed list including the style/item and quantity you require. We’re going to then mail our best price ranges to you.

We’re going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for aluminum foil cut, copper foil laser cut, engraved laser foil, foil cutting, foil cutting machines, foil laser cut wedding invitations, foil laser cutter, foil laser cutting, foil laser labels, foil tape for laser engraving, how to cut aluminum foil, laser cut copper foil, Laser Cut Foil, laser cut foil machine, laser cut foil stickers, laser cut wraps, laser cutter for plastics, laser cutter stickers, laser cutting aluminum foil, laser engraving foil, laser engraving gold foil, laser engraving labels, laser etching foil, laser foil engraving, laser foil for laser engraving, laser foil on leather, laser foils, To get more information about us as well as see all our products and solutions, you should visit our website. To get more information you should feel free to let us know. Thank you very much and wish your business always be great!

ADVANTAGES OF GALVO LASER ENGRAVER & MARKER 40

Best Entry-level GALVO Laser Machine

Technical Data

| Working Area (W * L) | 400mm * 400mm (15.7” * 15.7”) |

| Beam Delivery | 3D Galvanometer |

| Laser Power | 180W/250W/500W |

| Laser Source | CO2 RF Metal Laser Tube |

| Mechanical System | Servo Driven, Belt Driven |

| Working Table | Honey Comb Working Table |

| Max Cutting Speed | 1~1000mm/s |

| Max Marking Speed | 1~10,000mm/s |

Highlight of GALVO Laser Engraver & Marker 40

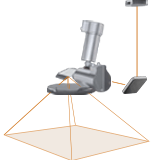

GALVO Head

GALVO laser uses high-speed, motor-driven mirrors to steer the laser beam through the lens. Aiming at the material in the laser marking field, the beam impacts the material at a greater or lesser inclination angle. The marking field size is defined by the deflection angle and the focal length of the optics. As there is no mechanical movement during cutting (with the exception of the mirrors), the laser beam can be guided over the workpiece at an extremely high speed. High efficiency and at the same time, high precision, make GALVO Laser Engraver & Marker 40 an ideal marking machine when it comes to short cycle times or high-quality markings.

For other GALVO views, diverse GALVO lenses are available. The biggest GALVO lens for this model is up to 800mm.

Fields of Application

Laser Cutting for Your Industry

Kiss Cutting

A laser tech that is widely used in many industries

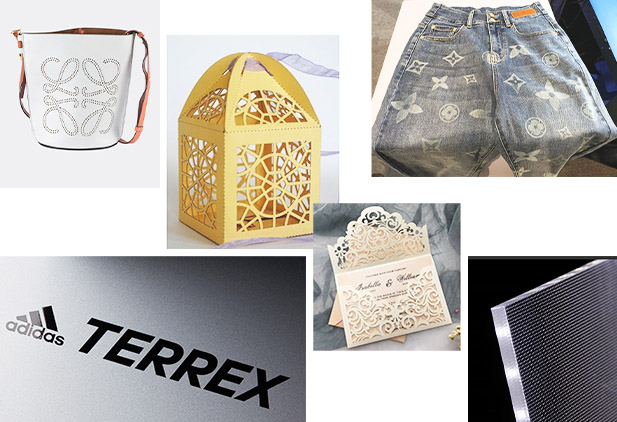

Common materials and applications

of GALVO Laser Engraver & Marker 40

We’ve designed laser systems for dozens of clients

Add yourself to the list!

Laser Cutting Foil

Benefits from Laser Cutting Foil

✔ Contactless processing, no need to fix the material – save your labor and time

✔ High flexibility in production – suitable for various patterns and batch

✔ Precise and accurate cutting results – cut, kiss cut, label, etc.

✔ No upfront costs for tool construction

Typical applications for Laser Cutting Foil

• Stickers

• Labels

• Patches

• Food packaging

Material information of Laser Cutting Foil

Foils made of different materials are used for diverse applications. Adhesive foil is for advertising use like small-batch custom stickers, trophy labels, etc. For aluminum foil, it is highly conductive. The superior oxygen barrier and moisture barrier properties make foil the preferred material for various packaging applications from food packaging to lidding film for pharmaceutical drugs.

However, with the development of printing, converting, and finishing labels in rolls, foil is also used in the fashion & apparel industry. MimoWork laser helps you to cover the shortage of conventional die cutters and provides a better digital workflow from the beginning to the end.

Related Foil Materials in the market:

Film, Venee

Factory supplied China Small Laser Cutting Machine, CO2 Laser Machine, To get more information about us as well as see all our products and solutions, you should visit our website. To get more information you should feel free to let us know. Thank you very much and wish your business always be great!