Aviation Carpet Laser Cutting

How to Cut Carpet with a Laser Cutter?

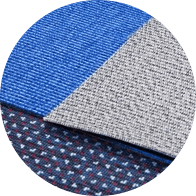

For aviation carpet, there are normally mainly three types of cutting technology: knife cutting, water jet cutting, laser cutting. Due to extremely long size and varied customized requirements for aviation carpet, laser cutter becomes the most suitable carpet cutting machine.

Timely and automatically sealing the edge of the aircraft blankets(carpet) with the help of thermal treatment from carpet laser cutter, constinuous as well as high precision carpet cutting through the conveyor system and digital control system, these provide great market flexibility and competition for small & medium businesses.

Laser technology is widely used in aviation & aerospace field, except for laser drilling, laser welding, laser cladding and 3D laser cutting for jet parts, laser cutting is playing a crucial part in carpet cutting.

Besides aviation carpet, home blanket, yacht mat and industrial carpet, carpet laser cutter can well perform functions for different types of designs and materials. Rigorous and precise carpet laser cutting makes the laser an important member of industrial carpet cutting machines. No need of model and tool replacement, laser machine can realize free and flexible cutting as design file, which prompts customized carpet market.

Carpet Laser Cutting

(Custom cut car floor mats with laser cutter)

◆ Precise laser cutting ensures the perfect match for outline and filling pattern

◆ Adjust to the premium laser power suitable for your material of carpet (mat)

◆ Digital CNC system is convenient for the operation

Any questions about carpet laser cutting & engraving

we are here to meet you!

Excellent Performance of Carpet Laser Cutter

Flat & clean cut edge

Customized shapes cutting

Enrich appearance from laser engraving

✔ No pulling deformation and performance damage with non-contact laser cutting

✔ Customized laser working table meets different sizes of carpet cutting

✔ No material fixation due to the vacuum table

✔ Clean and flat edge with heat treatment sealing

✔ Flexible shape and pattern cutting and engraving, marking

✔ Even extra long carpet can be auto-fed and cut due to the auto-feeder

Carpet Laser Cutter Recommendation

• Working Area: 1600mm * 1000mm (62.9” * 39.3 ”)

• Laser Power: 100W/150W/300W

• Working Area: 1600mm * 3000mm (62.9’’ *118’’)

• Laser Power: 150W/300W/450W

• Working Area: 1500mm * 10000mm (59” * 393.7”)

• Laser Power: 150W/300W/450W

Custom Your Laser Machine according to Your Carpet Size

Related Information for Laser Cutting Carpet

FAQs About Laser Cutting Carpet

Yes, you can laser cut carpet, especially synthetic materials like polyester, polypropylene, and nylon. A CO₂ laser cutter provides clean, precise edges and seals them to prevent fraying, making it ideal for custom shapes, logos, or fittings in aviation, automotive, and interior design. Compared to traditional cutting, it saves time, reduces material waste, and allows intricate designs without physical wear on tools. However, avoid carpets with PVC backing as they release harmful fumes, and always ensure proper ventilation during the process.

The best method for cutting carpet depends on the material, precision needs, and project scale. For simple installations, a sharp utility knife or carpet cutter works well for straight edges and small areas. For high-precision or custom shapes, especially with synthetic carpets like polyester or nylon, CO₂ laser cutting is the most efficient. It delivers clean, sealed edges that prevent fraying, allows intricate patterns or logos, and reduces material waste. For large-scale production or commercial applications, laser cutting is faster and more accurate than manual or die-cutting. Always ensure proper ventilation when cutting synthetic materials.

Cutting very thick carpet with a laser requires a high-power CO₂ laser machine capable of penetrating dense materials. Multiple passes at controlled speeds and power settings are often needed to achieve a clean, precise cut without burning or damaging the carpet. Laser cutting seals the edges to prevent fraying and allows for intricate designs even on thick carpets. Proper ventilation is essential to safely handle fumes during the process. This method offers greater accuracy and faster production compared to manual cutting tools, especially for synthetic carpets.

Yes, some carpet materials can release fumes when lasered. Proper ventilation and filtration systems are essential during the process.

Yes, laser cutting provides exact shapes and sizes, making it perfect for automotive, aviation, and custom interior carpet applications.