• What is Laser Cleaning Metal?

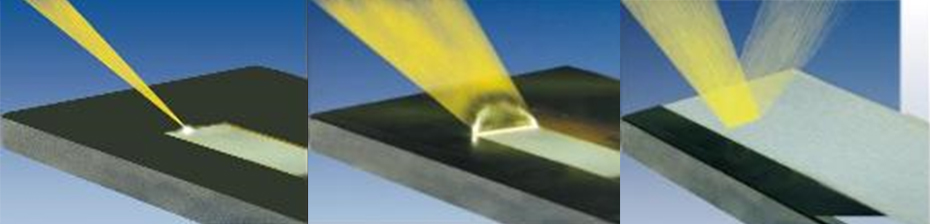

Fiber CNC Laser can be used to cut metals. The laser cleaning machine uses the same fiber laser generator to process metal. So, the question raised: does laser cleaning damage metal? To answer this question, we need to explain how lasers clean metal. The beam emitted by the laser is absorbed by the layer of contamination on the surface to be treated. The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), which produces shock waves. The shock wave breaks the contaminants into pieces and knocks them out.

In the 1960s, the laser was invented. In the 1980s, laser cleaning technology began to appear. In the past 40 years, laser cleaning technology has developed rapidly. In today's industrial production and material science fields, laser cleaning technology is even more indispensable.

How does laser cleaning work?

Laser cleaning technology is the process of irradiating the surface of the workpiece with a laser beam to peel off or vaporize the surface dirt, rust coating, etc., and clean the surface of the workpiece to achieve the purpose. The mechanism of laser cleaning has not yet been unified and clear. The more recognized ones are the thermal effect and vibration effect of laser.

Laser Cleaning

◾ The fast and concentrated pulse (1/10000 second) impacts with extremely high power (tens of Mio. W) and vaporizes the residue on the surface

2) Laser pulses are ideal for the removal of organic matter, such as dirt left on tire moulds

3) The short-term impact will not heat the metal surface and cause no damage to the base material

Comparison of laser cleaning and traditional cleaning methods

Mechanical friction cleaning

High cleanliness, but easy to damage the substrate

Chemical corrosion cleaning

No stress effect, but serious pollution

Liquid solid jet cleaning

Stress-free flexibility is high, but the cost is high and waste liquid treatment is complicated

High frequency ultrasonic cleaning

The cleaning effect is good, but the cleaning size is limited, and the workpiece needs to be dried after cleaning

▶ Advantage of Laser Cleaning Machine

✔ Environmental advantages

Laser cleaning is a "green" cleaning method. It does not need to use any chemicals and cleaning fluids. The waste materials cleaned are basically solid powders, which are small in size, easy to store, recyclable, and have no photochemical reaction and no pollution. It can easily solve the environmental pollution problem caused by chemical cleaning. Often an exhaust fan can solve the problem of waste generated by cleaning.

✔ Effectiveness

The traditional cleaning method is often contact cleaning, which has mechanical force on the surface of the cleaned object, damages the surface of the object or the cleaning medium adheres to the surface of the cleaned object, which cannot be removed, resulting in secondary pollution. Laser cleaning is non-abrasive and non-toxic. Contact, non-thermal effect will not damage the substrate, so that these problems are easily solved.

✔ CNC Control System

The laser can be transmitted through the optical fiber, cooperate with the manipulator and the robot, conveniently realize the long-distance operation, and can clean the parts that are difficult to reach by the traditional method, which can ensure the safety of personnel in some dangerous places.

✔ Convenience

Laser cleaning can remove various types of pollutants on the surface of various materials, achieving a cleanliness that cannot be achieved by conventional cleaning. Moreover, the pollutants on the surface of the material can be selectively cleaned without damaging the surface of the material.

✔ Low Operation Cost

Although the one-time investment in the initial stage of purchasing a laser cleaning system is high, the cleaning system can be used stably for a long time, with low operating costs, and more importantly, it can easily realize automatic operation.

✔ Cost calculation

The cleaning efficiency of a single unit is 8 square meters, and the operating cost per hour is about 5 kWh of electricity. You can take this into consideration and calculate the electricity cost

Recommended: Fiber Laser Cleaner

Choose the one that suits your requirement

Any confusions and questions for handheld laser cleaning machine?

Post time: Feb-14-2023