Hey there, laser enthusiasts and fabric fanatics! Buckle up because we're about to dive into the world of laser cut fabric, where precision meets creativity, and magic happens with a fabric laser cutting machine!

Multi Layer Laser Cut: Advantages

You've probably heard about CNC cutters handling multiple layers, but guess what? Lasers can do it too! Oh yeah, we're not just talking about your average laser cutting fabric; we're talking about multi-layer laser cut that delivers flawless edges and intricate designs like a boss. No more frayed edges or imprecise cuts - laser cutting fabric got your back!

Video Showcase | CNC vs Laser: The Efficiency Showdown

Ladies and gentlemen, it's time to embark on an exhilarating journey deep into the epic battle between CNC cutters and fabric laser-cutting machines.

In our previous videos, we provided a comprehensive overview of these cutting technologies, weighing their respective strengths and weaknesses.

But today, we're about to take it up a notch and reveal the game-changing strategies that will skyrocket your machine's efficiency, propelling it to outshine even the most formidable CNC cutters in the realm of fabric cutting.

Get ready to witness a revolution in cutting technology as we unlock the secrets to dominating the CNC vs. laser landscape.

Video Showcase | Can Laser Cut Multilayer Fabric? How it works?

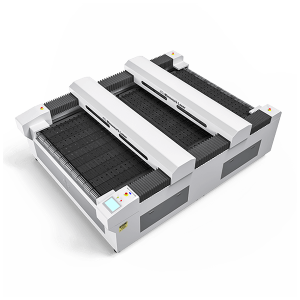

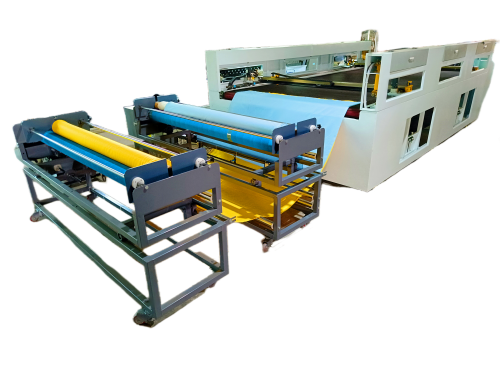

How to cut multiple layers of fabric? Can laser cut multi-layer fabrics? The video shows the advanced textile laser cutting machine that features laser cutting multilayer fabric.

With a two-layer auto-feeding system, you can simultaneously laser-cut double-layer fabrics, maximizing efficiency and productivity.

Our large-format textile laser cutter(industrial fabric laser cutting machine) is equipped with six laser heads, ensuring rapid production and high-quality output.

Discover the wide range of multi-layer fabrics compatible with our cutting-edge machine, and learn why certain materials, like PVC fabric, are not suitable for laser cutting.

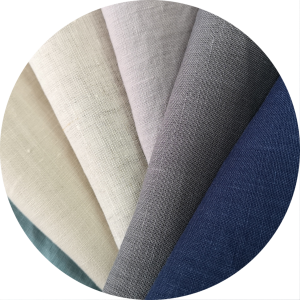

What Kind of Fabrics are Suitable: Multi Layer Laser Cut

Now, you might wonder, what kind of fabrics are suitable for this multi layer laser cut extravaganza? Hold onto your stitches, folks!

Fabrics containing PVC are a no-go (they melt and form cohesion).But fear not, cotton, denim, silk, linen, and rayon work great for laser cutting fabric.With a GSM ranging from 100 to 500 grams, they're the perfect contenders for multi-layers laser cutting.

Of course, fabric characteristics can vary like mood swings, so it's smart to do some testing or consult the laser cutting professionals for specific fabric suitability. Don't worry; we've got your back (and your fabric too)!

Suitable Fabrics Examples:

Having Questions about Multi Layer Laser Cutting

Contact us - We will Back you Up!

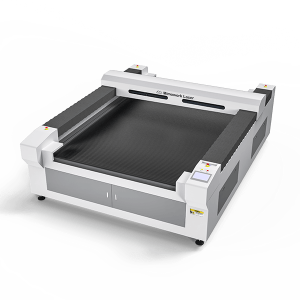

Recommended Laser Cutter for Multi Layer Laser Cutting

The Elephant in the Room: Material Feeding

Now, let's address the elephant in the laser room: material feeding! Here comes our multi-layer auto feeder, the superhero of alignment challenges for laser cut multi layer!

It holds two or three layers like a boss, saying goodbye to shifting and misalignment that ruin precision cuts for laser cut for paper. Say hello to smooth, wrinkle-free feeding that provides seamless and hassle-free operation.

Oh, and for those ultra-thin materials that are both waterproof and windproof (we see you, brave adventurers!), when fed through the laser, the air pumps might not be able to fix and secure the second or third layers of the materials, so we think an additional covering layer may be necessary for fixing them onto the working area.

This is a problem that we have never encountered with our customers so we can’t provide accurate information on this subject, feel free to do your research on this matter for multi layer laser cut.

In Conclusion

Multi layer laser cut, where precision, power, and possibilities unite for multi layer laser cut! Whether you're crafting fabulous fashion pieces or crafting intricate artwork with laser cut multi layer, this laser magic will leave you spellbound. Embrace the laser cutting fabric technology, get creative, and let your laser-cut dreams come to life with laser cut for paper!

And hey, if you need a laser buddy or have burning questions (not literally, of course) about multi layer laser cut, don't hesitate to reach out. We're here to support your laser cutting fabric adventure every step of the way. Until then, stay sharp, stay creative, and let the lasers do the talking for laser cut multi layer!

Who are we?

MimoWork is a high-tech enterprise specializing in the development of high-precision laser technology applications. Established in 2003, the company has consistently positioned itself as the preferred choice for customers in the global laser manufacturing field. With a development strategy focused on meeting market demands, MimoWork is dedicated to the research, production, sales, and service of high-precision laser equipment. They continuously innovate in the fields of laser cutting, welding, and marking, among other laser applications.

MimoWork has successfully developed a range of leading products, including high-precision laser cutting machines, laser marking machines, and laser welding machines. These high-precision laser processing equipment are widely utilized in various industries such as stainless steel jewelry, crafts, pure gold and silver jewelry, electronics, electrical appliances, instruments, hardware, automotive parts, mold manufacturing, cleaning, and plastics. As a modern and advanced high-tech enterprise, MimoWork possesses extensive experience in intelligent manufacturing assembly and advanced research and development capabilities.

Laser Cutting Multiple Layers of Fabric

Can be as Easy as One, Two, Three with Us

Post time: Aug-01-2023