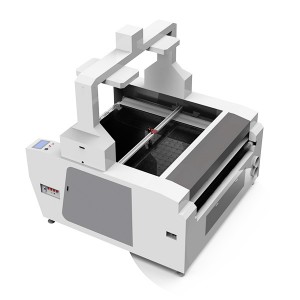

Sublimation Polyester Laser Cutter (160L)

Designed for & Excelled at Polyester Laser Cutting

Technical Data

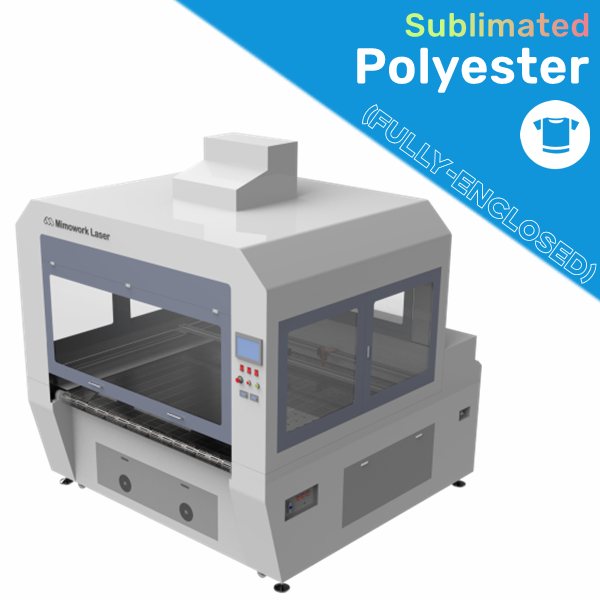

| Working Area (W *L) | 1600mm * 1200mm (62.9” * 47.2”) |

| Max Material Width | 62.9” |

| Laser Power | 100W / 130W / 150W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Two Laser Heads option is available

Unrivaled Choice for Laser Cutting Polyester

Design Highlights

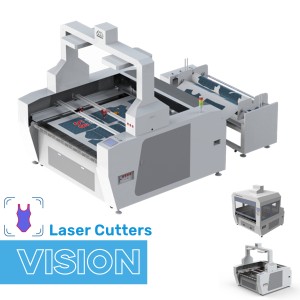

◆ Wide applications in industries such as digital printing, composite materials, clothing & home textiles

◆ Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◆ Evolutionary visual recognition technology and powerful software provide higher quality and reliability for your business.

◆ Auto-feeder provides automatic feeding, allowing unattended operation which saves your labor cost, lower rejection rate (optional)

R&D for Laser Cutting Polyester

Upgradable Options - Productivity Unleashed

Independent Dual Heads

Video Demonstration of Laser Cutting Sublimation Polyester

Find more videos about our vision laser cutters at our Video Gallery

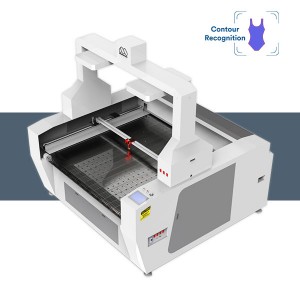

Vision Recognition System

✔ High cutting quality, accurate pattern recognition, and fast production

✔ Meeting the needs of small-patch production for local sports team

✔ Combination tool with your Calendar Heat Press

✔ No need for cutting file

Advantages & Highlights

Getting Ahead within the Industry

One of the key advantages of laser-cutting sublimation polyester is its ability to create intricate designs and patterns easily. The laser can cut through polyester fabrics with incredible precision, creating clean, sharp edges perfect for creating intricate shapes and designs.

Another advantage of laser-cutting sublimation polyester is its speed and efficiency. With traditional cutting methods, cutting fabric can be a time-consuming and laborious process. Laser cutting, on the other hand, is a much faster and more efficient method that can significantly reduce cutting time and increase productivity.

In addition to precision and speed, laser-cutting sublimation polyester also offers greater flexibility and versatility. The variety of software options and templates further enhances this versatility, allowing businesses to create various custom designs and products.

of Sublimation Polyester Laser Cutter (160L)

Materials: Polyester Fabric, Spandex, Nylon, Silk, Printed Velvet, Cotton, and other sublimation textiles

Applications: Active Wear, Sportswear (Cycling Wear, Hockey Jerseys, Baseball Jerseys, Basketball Jerseys, Soccer Jerseys, Volleyball Jerseys, Lacrosse Jerseys, Ringette Jerseys), Uniforms, Swimwear, Leggings, Sublimation Accessories (Arm Sleeves, Leg Sleeves, Bandanna, Headband, Face Cover, Masks)