Cutting Fabric with Laser Cutter Benefits and Limitations

Everything you want about fabric laser cutter

Laser cutting has become a popular method for cutting various materials, including fabric. The use of laser cutters in the textile industry offers several benefits, such as accuracy, speed, and versatility. However, there are also some limitations to cutting fabric with laser cutters. In this article, we will explore the benefits and limitations of cutting fabric with a laser cutter.

Benefits of Cutting Fabric with Laser Cutter

• Accuracy

Laser cutters offer a high degree of accuracy, which is essential in the textile industry. The precision of laser cutting allows for intricate and detailed designs, making it ideal for cutting patterns and designs on fabric. Additionally, Fabric laser cutting machine eliminates the risk of human error, ensuring that the cuts are consistent and accurate every time.

• Speed

Laser cutting is a fast and efficient process, making it ideal for large-scale textile production. The speed of laser cutting reduces the time required for cutting and production, increasing overall productivity.

• Versatility

Laser cutting offers a wide range of possibilities when it comes to cutting fabric. It can cut through a variety of materials, including delicate fabrics like silk and lace, as well as thick and heavy materials like leather and denim. Fabric laser cutting machine can also create intricate and complex designs that would be difficult to achieve with traditional cutting methods.

• Reduced Waste

Laser cutting is a precise cutting method that reduces waste in the production process. The accuracy of laser cutting ensures that fabric is cut with minimal scrap, maximizing the use of material and reducing waste.

Benefits of Cutting Fabric with Laser Cutter

• Limited Cutting Depth

Laser cutters have a limited cutting depth, which can be a limitation when cutting thicker fabrics. So we have more laser powers for cutting thicker fabrics in one pass, which can increase the efficiency and ensure the cutting quality.

• Cost

Laser cutters are a little expensive, which can be a barrier to smaller textile companies or individuals. The cost of the machine and the maintenance required can be prohibitive for some, making laser cutting an unrealistic option.

• Design Limitations

Laser cutting is a precise method of cutting, but it is limited by the design software used. The designs that can be cut are limited by the software, which can be a limitation for more complex designs. But don't worry, we have Nesting Software, MimoCut, MimoEngrave and more software for quick design and production. Additionally, the size of the design is limited by the size of the cutting bed, which can also be a limitation for larger designs. Based on that, MimoWork design different working areas for laser machines like 1600mm * 1000mm, 1800mm * 1000mm, 1600mm * 3000mm, 2500mm * 3000mm, etc.

In Conclusion

Cutting fabric with a laser cutter offers several benefits, including accuracy, speed, versatility, and reduced waste. However, there are also some limitations, including the potential for burnt edges, limited cutting depth, cost, and design limitations. The decision to use a laser cutter for cutting fabric depends on the needs and capabilities of the textile company or individual. For those with the resources and the need for precise and efficient cutting, Fabric laser cut machine can be an excellent option. For others, traditional cutting methods may be a more practical and cost-effective solution.

Video Display | A guide of choosing Laser Cutting Fabric

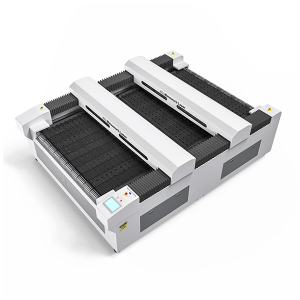

Recommended Fabric laser cutter

Any questions about the operation of Fabric Laser Cutter?

Post time: Apr-10-2023