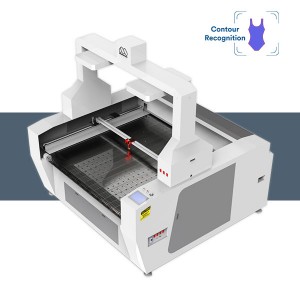

Plastic Laser Cutter and Engraver

Quality comes first; service is foremost; business is cooperation” is our business philosophy which is constantly observed and pursued by our company for Plastic Laser Cutter and Engraver, We focus on producing own brand and in combination with several experienced phrase and first-class equipment . Our goods you worth have.

Quality comes first; service is foremost; business is cooperation” is our business philosophy which is constantly observed and pursued by our company for custom laser cut jewelry, custom plastic cutting, laser cut plastic sheets, laser cut polyethylene, laser cut polypropylene, laser cutter for plastics, laser cutting plastic, laser engrave on plastic, laser engraver for plastic, laser engraving abs, Laser Engraving Plastic, laser etching on plastic, laser marking plastic, plastic laser engraver, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality items we provide, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and in depth parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We’re confident that we have been planning to share mutual results and build solid co-operation relations with our companions in this market. We’re looking forward to your inquiries.

Technical Data

| Working Area (W *L) | 1300mm * 900mm (51.2” * 35.4 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Step Motor Belt Control |

| Working Table | Honey Comb Working Table or Knife Strip Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

Multifunction in One Machine

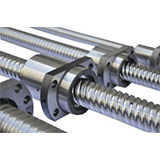

Ball & Screw

A ball screw is a mechanical linear actuator that translates rotational motion to linear motion with little friction. A threaded shaft provides a helical raceway for ball bearings which act as a precision screw. As well as being able to apply or withstand high thrust loads, they can do so with minimum internal friction. They are made to close tolerances and are therefore suitable for use in situations in which high precision is necessary. The ball assembly acts as the nut while the threaded shaft is the screw. In contrast to conventional lead screws, ball screws tend to be rather bulky, due to the need to have a mechanism to re-circulate the balls. The ball screw ensures high speed and high precision laser cutting.

Servo Motors

A servomotor is a closed-loop servomechanism that uses position feedback to control its motion and final position. The input to its control is a signal (either analog or digital) representing the position commanded for the output shaft. The motor is paired with some type of position encoder to provide position and speed feedback. In the simplest case, only the position is measured. The measured position of the output is compared to the command position, the external input to the controller. If the output position differs from that required, an error signal is generated which then causes the motor to rotate in either direction, as needed to bring the output shaft to the appropriate position. As the positions approach, the error signal reduces to zero, and the motor stops. Servo motors ensure higher speed and higher precision of the laser cutting and engraving.

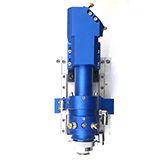

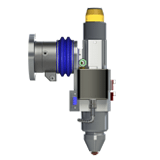

Mixed Laser Head

A mixed laser head, also known as a metal non-metallic laser cutting head, is a very important part of the metal & non-metal combined laser cutting machine. With this professional laser head, you can cut both metal and non-metal materials. There is a Z-Axis transmission part of the laser head that moves up and down to track the focus position. Its double drawer structure enables you to put two different focus lenses to cut the materials of different thicknesses without adjustment of focus distance or beam alignment. It increases cutting flexibility and makes the operation very easy. You can use different assist gas for different cutting jobs.

Auto Focus

It is mainly used for metal cutting. You may need to set a certain focus distance in the software when the cutting material is not flat or with different thickness. Then the laser head will automatically go up and down, keeping the same height & focus distance to match with what you set inside the software to achieve a consistently high cutting quality.

Video of Laser Cutting Acylic (PMMA)

Video of Laser Engraving Wood Board

Find more videos about our laser cutters at our Video Gallery

Fields of Application

Laser Cutting for Your Industry

Digital Printing

Clean and smooth edge with thermal treatment

Advertising & Gifts

Unique advantages of laser cutting signs & decorations

Common materials and applications

of Flatbed Laser Cutter 130

We’ve designed laser systems for dozens of clients

Add yourself to the list!

China OEM China Cutter, Digital Cutter, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality items we provide, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and in depth parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We’re confident that we have been planning to share mutual results and build solid co-operation relations with our companions in this market. We’re looking forward to your inquiries.

Laser Cutting Plastic

Professional Laser Cutting Solution for Plastic

Benefitting from the premium laser performance and compatibility between the laser wavelength and plastic absorbance, the laser machine stands out in the traditional mechanical technics with higher speed and more excellent quality. Featured the non-contact and forceless processing, plastic items can be turned into a smooth edge and brilliant surface without stress damage. Just because of that and inherent powerful energy, laser cutting becomes the ideal method in plastic customized prototype making and volume manufacturing.

Benefits from Laser Cutting Plastic

Clean & smooth edge

internal-laser-cut

Flexible internal-cut

Pattern contour cutting

✔ Minimum heat affected area only for the incision

✔ Brilliant surface due to the contactless and forceless processing

✔ Clean and flat edge with the steady and powerful laser beam

✔ Accurate contour cutting for the patterned plastic

✔ Fast speed and automatic system greatly improve the efficiency

✔ High repeated accuracy and fine laser spot ensures consistent high quality

✔ No tool replacement for customized shape

✔ Laser Marking Machine brings intricate patterns and detailed marking

Laser cutting can meet varied plastics production with different properties, sizes, and shapes. Supported by the pass-through design and customized working tables from MimoWork, you can cut and engrave on the plastic without the limit of material formats. Besides Plastic Laser Cutter, UV Laser Marking Machine and Fiber Laser Marking Machine help to realize the plastic marking, especially for the identification of the electronic components and precise instruments.

Typical applications for Laser Cutting Plastic

◾ Jewelry

◾ Films

◾ Foil

◾ Decorations

◾ Keyboards

◾ Packaging

◾ Models

◾ Custom phone cases

◾ Printed circuit boards (PCB)

◾ Automotive parts

◾ Identification tags

◾ Switch and button

◾ Plastic reinforcement

◾ Electronic components

◾ Plastic degating

◾ Sensor