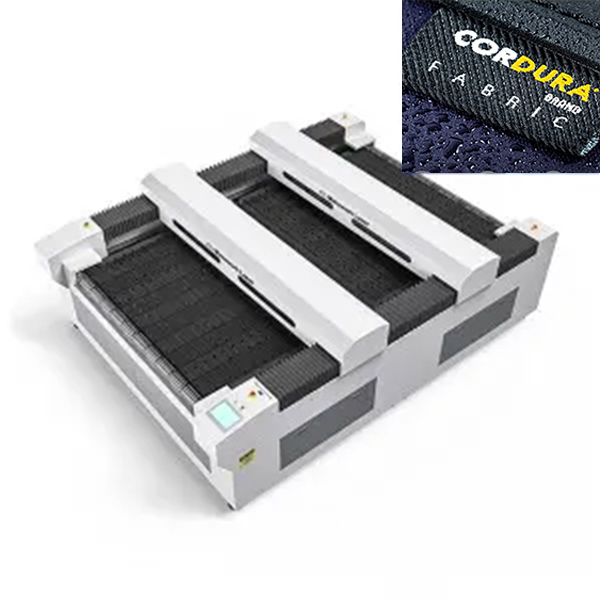

Cordura Fabric - China Factory, Suppliers, Manufacturers

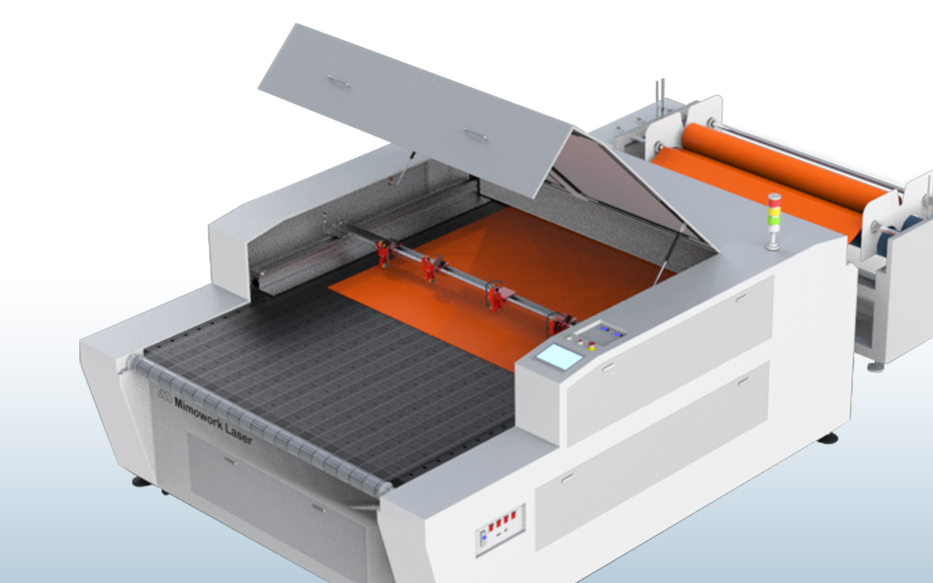

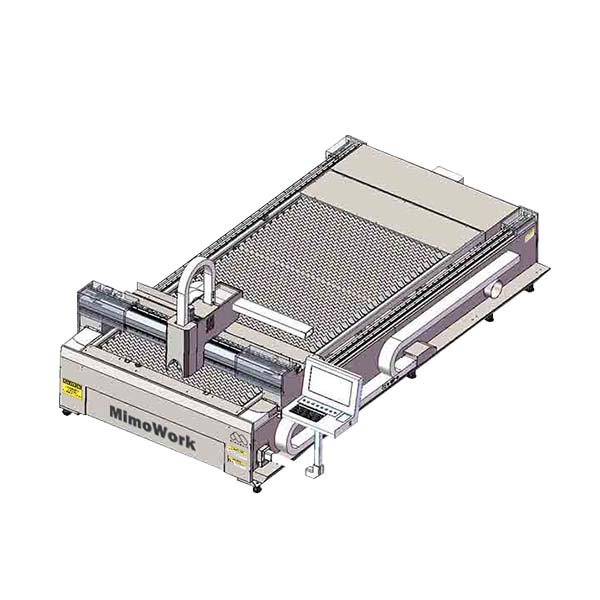

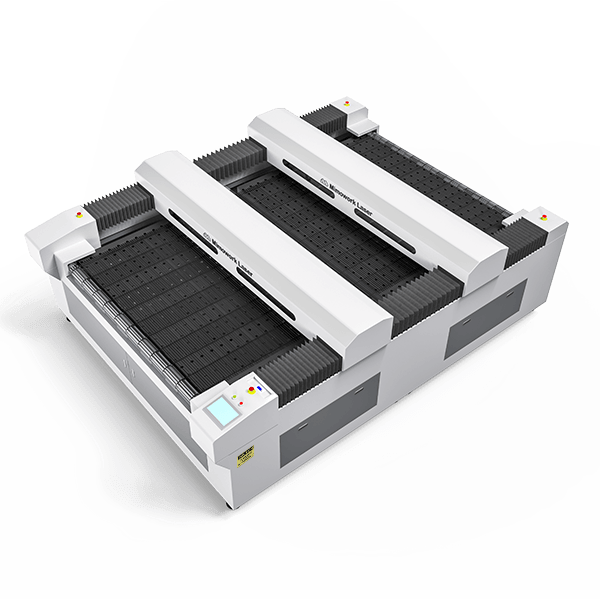

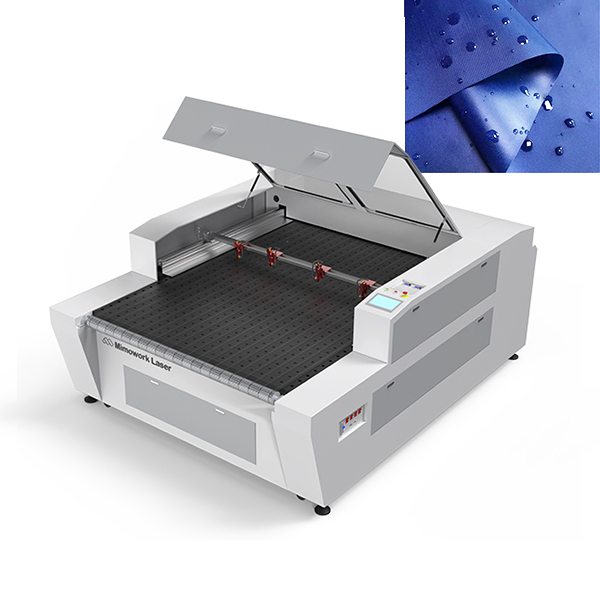

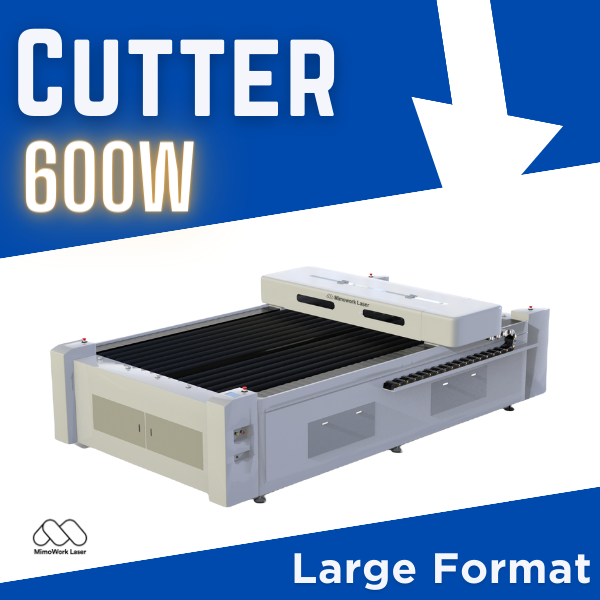

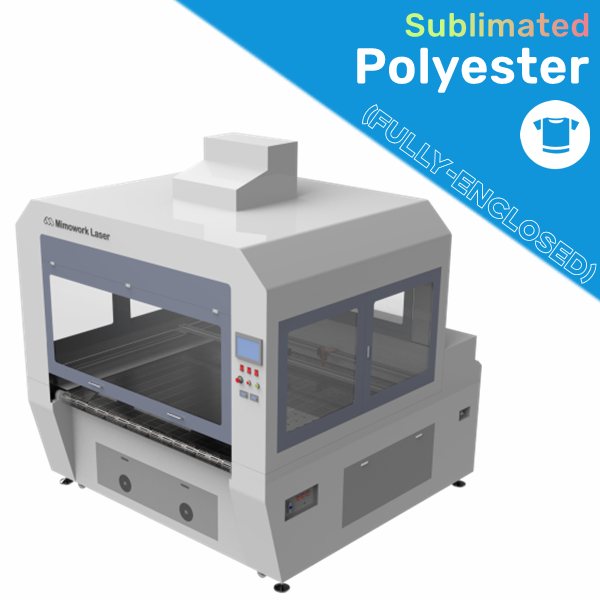

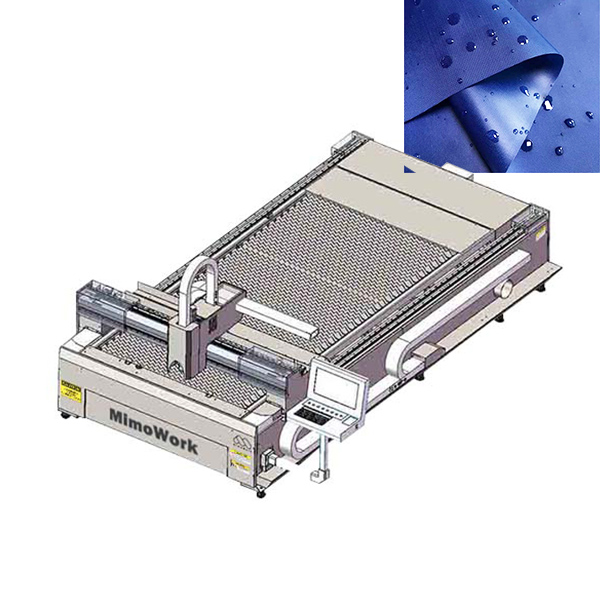

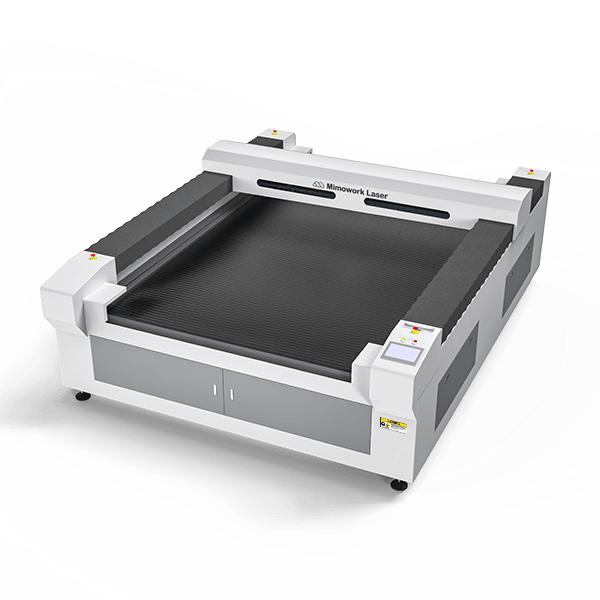

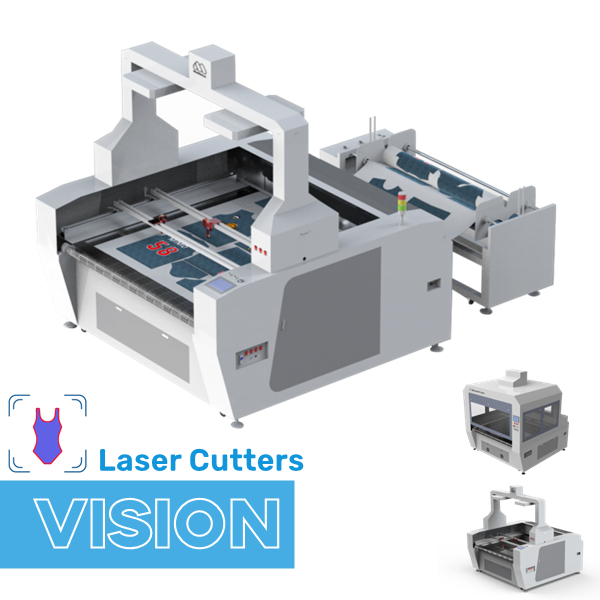

We also offer you product sourcing and flight consolidation expert services. We've our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for Cordura Fabric, Wide Laser Cutting For Textile , Laser Cut Shoes , Contour Laser Cutter Machine ,Flatbed Fiber Laser Cutter Wood . We are looking forward to cooperating with all customers from at home and abroad. Moreover, customer satisfaction is our eternal pursuit. The product will supply to all over the world, such as Europe, America, Australia,Portugal , Greek ,United States , Bhutan .We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

Related Products