Laser Cut Polyester

Laser cutting polyester is popular and common. This is not only due to the CO2 laser's compatibility (which is well-absorbed by polyester material) but also thanks to the high level of automation of the laser cutting machine.

We know polyester fabric has excellent properties in moisture-wicking, quick-drying, wrinkle resistance and durability. These make polyester the important composition of sportswear, daily clothing, home textile and outdoor gear. To match the boom of polyester items, fabric laser cutting machine is optimized and upgraded.

There are two basic types of polyester laser cutters designed for your solid polyester fabric and dye-sublimated polyester fabric. Besides laser cutting polyester fabric, CO2 laser has exceptional performance in laser cutting polyester film and laser cutting polyester felt. Now follow with us, explore the world of laser cutting polyester.

Table of Content:

◼ Laser Processing For Polyester

1. Laser Cutting Polyester

Can you cut polyester without it fraying? The answer from laser cutter is YES!

Laser cutting polyester especially polyester fabric is widely used. With the fine laser spot and precise laser cutting path, the laser cutting machine can accurately cut the polyester fabric into pieces used in clothing, sportswear, or banners.

The high precision of laser cutting polyester brings a clean and smooth edge. The heat from the CO2 laser is able to seal the edge instantly, getting rid of post-processing.

The laser cutter, more exactly, the laser beam, is in a spot to contact and cut through the polyester. That's why there is no limitation in cutting shapes, patterns, and sizes. You can use the polyester laser cutter to realize tailor-made designs, with perfect cutting effects.

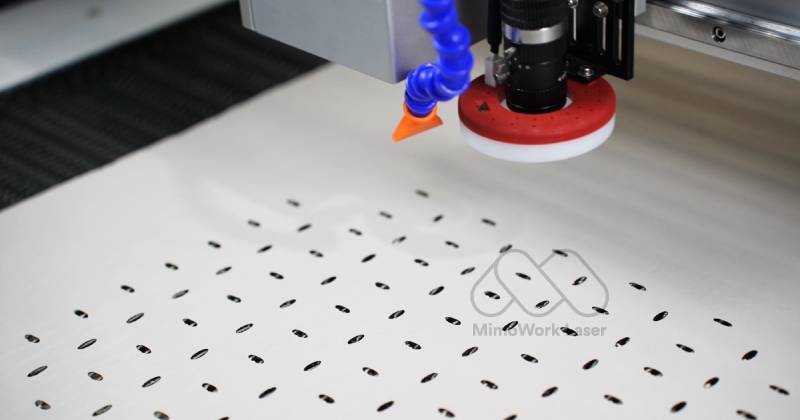

2. Laser Perforating in Polyester

Laser perforating is like laser cutting polyester, but the difference is laser cutting small holes in polyester. We know the laser spot is so thin can reach 0.3mm, which means laser cutting micro holes is possible.

You can customize the shapes, and sizes of the holes, including the spaces between various holes. The application of laser cutting holes in polyester is widely used in sportswear, to realize great breathability. Plus, laser perforation features fast speed, which is highly efficient for polyester processing.

3. Laser Marking on Polyester

Laser marking on polyester (also called laser engraving polyester) is a special marking technology. Whether for engraving on polyester T-shirts, bags, or towels, laser machine can make it. The fine laser spot and precise power and speed control, make the engraving or marking effect fantastic. You can engrave logo, graphic, text, name, or any design on polyester fabric or felt. The permanent mark didn't wear or disappear. You can decorate home textiles or put marks to identify unique clothing.

Unlocking the secrets to fast and automatic sublimation sportswear cutting, the MimoWork vision laser cutter emerges as the ultimate game-changer for sublimated clothing, including sportswear, leggings, swimwear, and more. This cutting-edge machine introduces a new era in the world of apparel production, thanks to its accurate pattern recognition and precise cutting capabilities.

Dive into the realm of high-quality printed sportswear, where intricate designs come to life with unparalleled precision. But that's not all – the MimoWork vision laser cutter goes above and beyond with its auto-feeding, conveying, and cutting features.

Camera Laser Cutter for Sportswear & Clothing

We're diving into the realms of advanced and automatic methods, exploring the wonders of laser cutting printed fabrics and activewear. Equipped with a cutting-edge camera and scanner, our laser cutting machine takes efficiency and yields to unprecedented heights. In our captivating video, witness the magic of a fully automatic vision laser cutter designed for the world of apparel.

The dual Y-axis laser heads deliver incomparable efficiency, making this camera laser-cutting machine a standout performer in laser cutting sublimation fabrics, including the intricate world of jersey materials. Get ready to revolutionize your approach to laser cutting with efficiency and style!

How to Laser Cut Sublimation Teardrop

How to accurately cut sublimated flags? The large vision laser cutting machine for fabric is the simplest tool to realize automatic production in the sublimation advertising industry. Such as teardrop flags, banners, exhibition displays, backdrop, etc.

This video introduces how to operate the camera laser cutter and demonstrates the teardrop flag laser cutting process. Precise cutting along the printed pattern's contour, and fast cutting speed.

◼ Benefits From Laser Cutting Polyester

How to cut polyester fabric fast & accurately? With the polyester laser cutter, you can get the perfect polyester pieces for sublimation polyester or solid polyester. High efficiency comes with top quality.

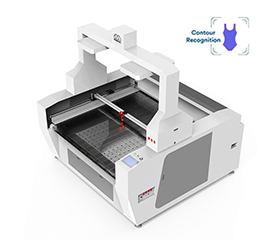

Varied working Tables and optional Contour Recognition Systems contribute to laser cutting varieties of polyester fabric items at any size, any shape, and printed pattern.

Not only that, a laser cutter can get rid of worries about material distortion and damage thanks to non-contact processing.

With a reasonable layout and precise cutting, the polyester laser cutter helps to maximize the cost savings of raw materials and processing.

Automatic feeding, conveying, and cutting can greatly enhance your production efficiency.

Clean and flat edge

Any-angle circular cutting

High efficiency & output

✔ Clean and flat edges and no materials damage

✔ Accurate contour cutting with Contour Recognition System

✔ High efficiency with continuous auto-feeding

✔ Suitable for cutting any printed pattern and shape

✔ CNC automatic control system, saving labor and time cost

✔ High repeated accuracy, ensuring consistent high quality

✔ No tool abrasion and replacing

✔ Eco-friendly processing method

We know that polyester fabric has a wide range of applications from clothing to industrial products. Different polyester fabric applications come with varying properties of material and processing requirements. Laser cutter, exactly the CO2 laser cutter, is a perfect cutting tool for various polyester fabric products.

Why say that? CO2 laser has an inherent advantage in cutting fabric, due to great fabric adsorption to CO2 laser, including polyester. Also, laser cutting has no limitation to cutting design, so any shape, any size can be laser cut. That provides a wide versatility for laser cutting various polyester fabric products. Such as sportswear, bags, filter cloths, banners, etc.

◼ Applications of Laser Cutting Polyester Felt

Laser cutting polyester felt offers a wide range of applications.

Including crafts and DIY projects, home decor items like wall art and coasters, fashion accessories such as hats and bags, office supplies like organizers and mouse pads, automotive interiors, soundproofing solutions, and promotional items.

The precision and versatility of laser cutting make it ideal for creating intricate designs and custom shapes.

Using a CO2 laser to cut polyester felt is particularly advantageous because it produces clean, smooth edges without fraying.

Its efficiency in cutting complex patterns, and its non-contact nature, minimize material distortion and ensure high-quality results.

◼ Applications of Laser Cutting Polyester Film

Laser cutting polyester film is widely used in various industries due to its precision and versatility. Applications include creating flexible circuits, stencils, screen printing, protective overlays, packaging materials, labels, and decals.

Laser cutting provides clean, accurate cuts without causing material deformation. That is essential for maintaining the integrity and functionality of polyester film products. The process is highly efficient, allowing for intricate designs and customization, making it ideal for both prototyping and large-scale production.

◼ Recommended Polyester Laser Cutter

• Laser Power: 100W/ 150W/ 3000W

• Working Area: 1800mm * 1300mm (70.87’’ * 51.18’’)

• Laser Power: 100W/150W/300W

• Working Area: 1600mm*1000mm (62.9” *39.3 ”)

• Extended Collecting Area: 1600mm * 500mm

• Laser Power: 150W/300W/500W

• Working Area: 1600mm * 3000mm (62.9’’ *118’’)

◼ Material Information Of Laser Cutting Polyester Fabric

As a generic term for artificial polymer, polyester(PET) now often is regarded as a functional synthetic material, occurring on the industry and commodity items. Made of polyester yarns and fibers, woven and knitted polyester is characterized by inherent properties of resistance to shrinking and stretching, wrinkle resistance, durability, easy cleaning, and dying.

Polyester is given more traits to enhance customers’ wearing experience, expand industrial textiles’ functions. Such as cotton-polyester is featured with high strength, weather resistance, breathable and anti-static, which make it the usual raw material of daily clothing and sportswear. Also, industrial applications are very common, like conveyor belt fabrics, seat belts, polyester felt.

Suitable processing technology can give full play to the excellent characteristics of polyester. The laser system has always been the first choice for polyester processing, whether it is clothing industry, home textile industry, soft interior decoration, shoe material industry, or mechanical processing, high-end technology industry, laser cutting, laser marking and laser perforating on polyester from MimoWork Laser Cutter help to improve processing efficiency and explore more possibilities on materials application and customization for you.

◼ FAQ of Laser Cutting Polyester

# Can You Laser Cut Polyester?

Yes, polyester fabric can be laser cut.

CO2 lasers are commonly used for cutting polyester fabrics due to their versatility and ability to cut through a wide range of materials.

By using the right laser settings and techniques, polyester fabric can be effectively laser cut to achieve precise and clean cuts,

making it suitable for various applications in garment manufacturing, textiles, and other industries.

# How To Laser Cut Fabric?

Laser cutting fabric like polyester and nylon is so easy and automatic.

You only need a digital cutting file, a roll of polyester, and a fabric laser cutter.

Upload the cutting file and set the relevant laser parameters, the rest of the processing will be finished by the laser cutter.

The laser cutter is able to auto-feed the fabric and automatically cut the fabric into pieces.

# Is It Safe To Laser Cut Polyester?

Yes, laser cutting polyester is generally safe when proper safety precautions are taken.

Polyester is a common material for laser cutting because it can produce precise and clean cuts.

Usually, we need to equip a well-performed ventilation device,

and set proper laser speed & power based on material thickness and gram weight.

For detailed laser setting advice, we suggest you consult our laser experts who are experienced.