What is Laser Engraved Leather?

What is laser engraving on leather? It is the revolutionary process that is transforming leathercraft. This innovative process effortlessly transforms even the most intricate designs into reality with unmatched precision and speed.

Its appeal lies in pure efficiency: one machine does it all. No physical tools or costly dies are needed. This non-contact method guarantees flawless, consistent results and stunning detail on every piece, making waste a thing of the past.

Whether you're a hobbyist exploring new ideas or a professional streamlining production, laser engraving is the ultimate tool to unlock creativity and productivity in perfect harmony.

from

Laser Engraved Leather Lab

So, what makes a laser engraver the tool for leather? And is it truly superior to traditional methods like stamping or carving?

Now, take your questions and ideas, and let's begin by understanding the machine at the heart of this craft.

Dive into the world of laser leather engraving.

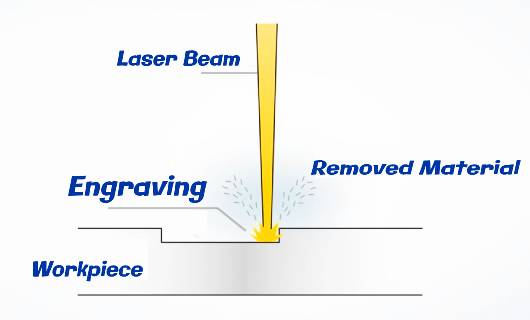

▶ What is laser engraving?

Is laser leather engraving really superior to other traditional engraving methods like stamping, carving, or embossing?The most convincing answer isn't just in words—it's in seeing the difference in action. In the video below, we put both techniques to the test on the same design.

▶ Tools Comparison: Carving VS. Stamping VS. Laser

Explore the Evolution of Leathercraft: From traditional hand stamping and carving to the leap of modern laser technology. This video compares the pros and cons of three fundamental techniques and reveals why the CO2 laser engraving machine is becoming the preferred tool for realizing intricate designs, rapid prototyping, and even business scalability.

▶ What is the best laser for engraving leather?

CO2 Laser VS Fiber Laser VS Diode Laser

Recommend: CO2 Laser

Now, based on these criteria, which CO2 laser engraver models come highly recommended?

Recommended CO2 Laser Engraver for Leather

From MimoWork Laser Series

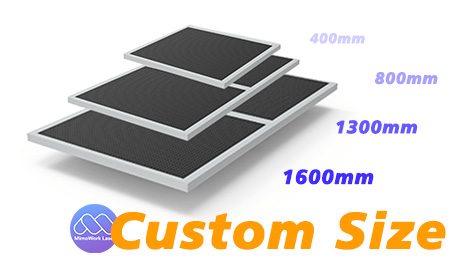

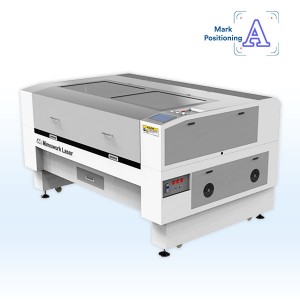

Working Table Size: 1300mm * 900mm (51.2” * 35.4 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 130

A small laser cutting and engraving machine that can be fully customized to your needs and budget. The two-way penetration design allows you to place materials that extend beyond the cut width. If you want to achieve high-speed leather engraving, we can upgrade the step motor to a DC brushless servo motor and reach the engraving speed of 2000mm/s.

Working Table Size: 1600mm * 1000mm (62.9” * 39.3 ”)

Laser Power Options: 100W/150W/300W

Overview of Flatbed Laser Cutter 160

Customized leather products in different shapes and sizes can be laser engraved to meet continuous laser cutting, perforating, and engraving. The enclosed and solid mechanical structure provides a safe and clean working environment during laser cutting on leather. Besides, the conveyor system is convenient for rolling leather feeding and cutting.

Working Table Size: 400mm * 400mm (15.7” * 15.7”)

Laser Power Options: 180W/250W/500W

Overview of Galvo Laser Engraver 40

MimoWork Galvo Laser Marker and Engraver is a multi-purpose machine used for leather engraving, perforating, and marking (etching). Flying laser beam from a dynamic lens angle of inclination can realize fast processing within the defined scale. You can adjust the height of the laser head to fit the processed material’s size. Fast engraving speed and fine engraved details make the Galvo Laser Engraver your good partner.

▶ Advantages of Laser Cutting & Engraving Leather

Crisp & clean cut edge

Subtle engraving details

Repeated even perforating

▶ How to Choose Laser Engraving Machine for Leather?

You Need To Consider

How to Choose Leather for Laser Engraving?

▶ What leather types are suitable for laser engraving?

Laser engraving is generally suitable for a variety of leather types, but the effectiveness can vary based on factors such as the leather's composition, thickness, and finish. Here are some common types of leather that are suitable for laser engraving:

Natural leather, genuine leather, raw or treated leather like napped leather, and similar textiles such as leatherette, and Alcantara can be laser cut and engraved. Before engraving on a large piece, it's advisable to perform test engravings on a small, inconspicuous scrap to optimize settings and ensure the desired results.

▶ How to select and prepare the leather to be engraved?

How to Laser Engrave Leather

Video Display - Laser Engraving & Perforating Leather

▶ Operation Guide: How to Laser Engrave Leather?

Depending on the CNC system and precise machine components, the acrylic laser cutting machine is automatic and easy to operate. You just need to upload the design file to the computer, and set the parameters according to material features and cutting requirements. The rest will be left to the laser. It's time to free your hands and activate creativity and imagination in mind.

Step 1. prepare machine and leather

Leather Preparation: You can use the magnet to fix the leather to keep it flat, and better to wet the leather before laser engraving, but not too wet.

Laser Machine: choose the laser machine depending on your leather thickness, pattern size, and production efficiency.

▶

Step 2. set software

Design File: import the design file into the laser software.

Laser Setting: Set the speed and power for the engraving, perforating, and cutting. Test the setting using the scrap before real engraving.

▶

Step 3. laser engrave leather

Start Laser Engraving: ensure the leather is in the right position for accurate laser engraving, you can use a projector, template, or laser machine camera to position.

▶ What You Can Make with Leather Laser Engraver?

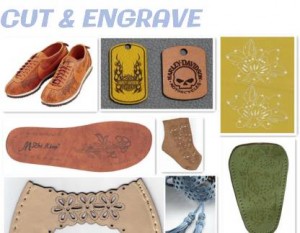

① Laser Engraving Leather

laser engraved leather keychain, laser engraved leather wallet, laser engraved leather patches, laser engraved leather journal, laser engraved leather belt, laser engraved leather bracelet, laser engraved baseball glove, etc.

② Laser Cutting Leather

laser cut leather bracelet, laser cut leather jewelry, laser cut leather earrings, laser cut leather jacket, laser cut leather shoes, laser cut leather dress, laser cut leather necklaces, etc.

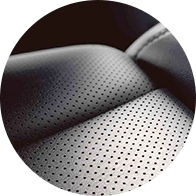

③ Laser Perforating Leather

perforated leather car seats, perforated leather watch band, perforated leather pants, perforated leather motorcycle vest, perforated leather shoes upper, etc.

What's your leather application?

Let's know and offer you advice

The great engraving effect benefits from the right leather laser engraver, suitable leather type, and correct operation. Laser engraving leather is easy to operate and master, but if you plan to start a leather business or improve your leather productivity, having a little knowledge of basic laser principles and machine types is better.

✦ Always testing the material firstly before real laser engraving

▶ Some Tips & Attentions of laser engraving leather

Proper Ventilation: Ensure proper ventilation in your workspace to eliminate smoke and fumes generated during engraving. Consider using a fume extraction system to maintain a clear and safe environment.

Focus the Laser: Properly focus the laser beam on the leather surface. Adjust the focal length to achieve sharp and precise engraving, especially when working on intricate designs.

Masking: Apply masking tape to the leather surface before engraving. This protects the leather from smoke and residue, providing a cleaner finished look. Remove the masking after engraving.

Adjust Laser Settings: Experiment with different power and speed settings based on the type and thickness of the leather. Fine-tune these settings to achieve the desired engraving depth and contrast.

Monitor the Process: Keep a close eye on the engraving process, especially during the initial tests. Adjust settings as needed to ensure consistent and high-quality results.

▶ Machine Upgrade to Simplify Your Work

Video: Projector Laser Cutter & Engraver for Leather

This video showcases how a projector-positioning laser cutter precisely projects shoe patterns onto leather and effortlessly executes cutting, engraving, and perforating—a versatile solution for efficient, high‑quality production.

FAQs

The optimal laser engraving settings for leather can vary based on factors such as the type of leather, its thickness, and the desired outcome. It's crucial to conduct test engravings on a small, inconspicuous section of the leather to determine the best settings for your specific project. Detailed information to contact us >>

Begin by gently brushing the laser-engraved leather with a soft brush to remove any loose dirt or dust. To clean the leather, use a mild soap that is specifically designed for leather. Dip a clean, soft cloth in the soap solution and wring it out so that it is damp but not soaking wet. Gently rub the cloth over the engraved area of the leather, being careful not to scrub too hard or apply too much pressure. Make sure to cover the entire area of the engraving. Once you have cleaned the leather, rinse it thoroughly with clean water to remove any soap residue. After the engraving or etching is complete, use a soft brush or cloth to gently remove any debris from the paper surface. Once the leather is completely dry, apply a leather conditioner to the engraved area. More information to check out the page: How to clean leather after laser engraving

Begin by gently brushing the laser-engraved leather with a soft brush to remove any loose dirt or dust. To clean the leather, use a mild soap that is specifically designed for leather. Dip a clean, soft cloth in the soap solution and wring it out so that it is damp but not soaking wet. Gently rub the cloth over the engraved area of the leather, being careful not to scrub too hard or apply too much pressure. Make sure to cover the entire area of the engraving. Once you have cleaned the leather, rinse it thoroughly with clean water to remove any soap residue. After the engraving or etching is complete, use a soft brush or cloth to gently remove any debris from the paper surface. Once the leather is completely dry, apply a leather conditioner to the engraved area. More information to check out the page: How to clean leather after laser engraving

We should wet the leather before laser engraving. This will make your engraving process more effective. However, you also need to pay attention to the leather should not be too wet. Engraving too wet leather will damage the machine.

> What information you need to provide?

> Our contact information

Any confusion or questions for the leather laser engraver, just inquire us at any time

Post time: Jan-08-2024