Introduction

Laser cutting and engraving produce harmful fumes and fine dust. A laser fume extractor removes these pollutants, protecting both people and equipment.When materials like acrylic or wood are lasered, they release VOCs and particles. HEPA and carbon filters in extractors capture these at the source.

This guide explains how extractors work, why they’re essential, how to choose the right one, and how to maintain it.

Benefits and Functions of Laser Fume Extractors

Protects Operator Health

Effectively removes harmful fumes, gases, and dust to reduce respiratory irritation, allergies, and long-term health risks.

Improves Cutting & Engraving Quality

Keeps the air clean and laser path visible, ensuring high precision and consistent results.

Extends Machine Lifespan

Prevents dust buildup on sensitive components like lenses and rails, reducing wear and maintenance needs.

Reduces Odors & Enhances Work Comfort

Activated carbon filters absorb strong smells from materials like plastic, leather, and acrylic.

Ensures Safety and Regulatory Compliance

Meets air quality and occupational safety standards in workshops, labs, and industrial environments.

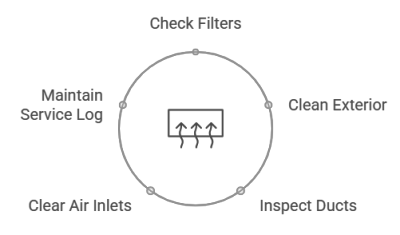

Daily Maintenance Tips

Check and Replace Filters Regularly

Pre-filters: Inspect every 2–4 weeks

HEPA & carbon filters: Replace every 3–6 months depending on usage, or follow the indicator light

Clean Exterior and Inspect Ducts

Wipe down the unit and ensure all hose connections are tight and leak-free.

Keep Air Inlets and Outlets Clear

Avoid dust buildup or blockages that reduce airflow and cause overheating.

Maintain a Service Log

Especially useful in industrial or educational settings for proper documentation and preventive care.

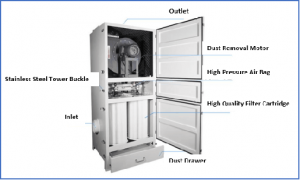

Reverse Air Pulse Industrial Fume Extractor

——Filter cartridge vertical structure, integrated design, practical and cost-effective

Integrated Structure

Integrated structure, small footprint.

The default fixed feet design is stable and solid, and movable universal wheels are optional.

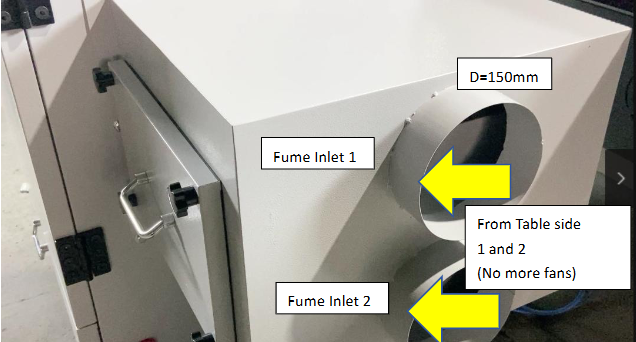

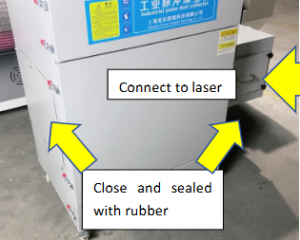

The air inlet adopts the left and right air inlet and top air outlet design.

Fan Power Unit

Medium and high pressure centrifugal fan with good dynamic balance.

Professional shock absorption ratio design, reducing resonance frequency, excellent overall vibration performance.

High-efficiency silencing design with noticeable noise reduction.

Cartridge Filter Unit

The filter is made of polyester fiber PTFE film material with a filtration accuracy of 0.5μm.

Pleated cartridge filter structure with large filtration area.

Vertical installation, easy to clean. Small wind resistance, high filtration accuracy, in line with emission standards.

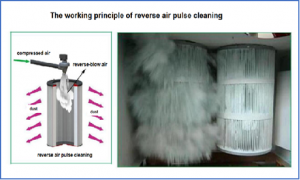

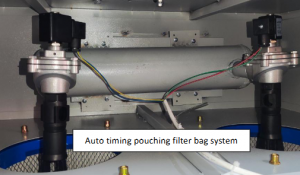

Reverse Air Pulse Unit

Stainless steel gas tank, large capacity, high stability, no hidden dangers of rust, safe and reliable.

Automatic reverse air pulse cleaning, adjustable spraying frequency.

The solenoid valve adopts professional imported pilot, low failure rate and strong durability.

How to Put Filter Bag Back

1. Rotate the Black Hose Back to Top Middle.

2. Rotate the white filter bag back to top blue ring.

3. This is Activated carbon filter box. Normal model without this box, can directly connect to one side open cover.

4. Connect two bottom exhaust pipes to the filter box.(normal model without this box, can directly connect to one side open cover)

5. We only use one side box to connect to two exhaust pipes.

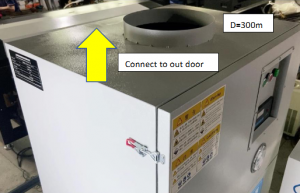

6. Connect outlet D=300mm

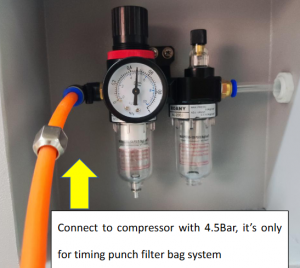

7. Connect air inlet for Auto timing pouching filter bag system. Air pressure can be 4.5Bar enough.

8. Connect to compressor with 4.5Bar, it’s only for timing punch filter bag system.

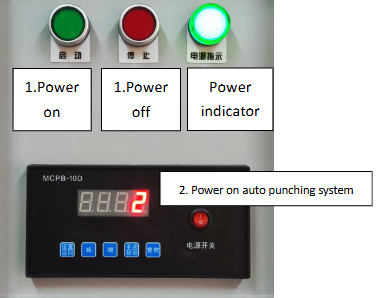

9. Power on the Fume system by two power switches...

Recommend Machines

Want To Know More About Fume Extractor?

Start a Conversation Now!

FAQs

A fume extractor is a device used to remove harmful fumes and gases generated during processes such as welding, soldering, laser processing, and chemical experiments. It draws in contaminated air with a fan, filters it through high-efficiency filters, and releases clean air, thereby protecting workers’ health, keeping the workspace clean, and complying with safety regulations.

The basic method of fume extraction involves using a fan to draw in contaminated air, passing it through a multi-stage filtration system (such as HEPA and activated carbon filters) to remove particulates and harmful gases, and then releasing the clean air back into the room or venting it outside.

This method is efficient, safe, and widely used in industrial, electronic, and laboratory settings.

The purpose of a fume extractor is to remove harmful fumes, gases, and particulates generated during work processes, thereby protecting the health of operators, preventing respiratory issues, maintaining clean air, and ensuring the work environment meets safety and environmental standards.

Dust extractors and dust collectors both remove airborne dust, but they differ in design and application. Dust extractors are typically smaller, portable, and designed for fine, localized dust removal—such as in woodworking or with power tools—focusing on mobility and efficient filtration. Dust collectors, on the other hand, are larger systems used in industrial settings to handle high volumes of dust, prioritizing capacity and long-term performance.

Post time: Jun-10-2025