Chii chinonzi laser welding? Tsananguro yeLaser Welding! Zvese zvaunoda kuziva nezve Laser Welding, kusanganisira musimboti mukuru uye main process parameters!

Vatengi vazhinji havanzwisisi nheyo dzekushanda kwemuchina we laser welding, tisingatauri nezvekusarudza muchina we laser welding wakakodzera, zvisinei Mimowork Laser iripo kuti ikubatsire kuita sarudzo chaiyo uye kukupa rumwe rutsigiro kuti ikubatsire mukunzwisisa laser welding.

Chii chinonzi Laser Welding?

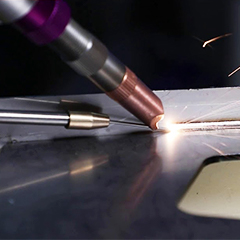

Kushongedza neLaser rudzi rwekushongedza kunyungudutsa, uchishandisa laser beam senzvimbo yekupisa yewelding, musimboti wewelding ndewekuti nzira chaiyo yekukurudzira active medium, ichigadzira resonant cavity oscillation, uye yozoshanduka kuita stimulated radiation beam, kana workpiece neworkpiece zvasangana, simba rinotorwa neworkpiece, kana tembiricha yasvika pakunyunguduka kwezvinhu inogona kusungirirwa.

Zvichienderana nehurongwa hukuru hwedziva rekukwevera, kukwevera nelaser kune nzira mbiri huru dzekukwevera: kukwevera nekupisa uye kukwevera nepakati pekiyi. Kupisa kunokonzerwa nekukwevera nekupisa kunoparadzirwa kuchinhu chebasa kuburikidza nekutamiswa kwekupisa, kuitira kuti pamusoro peweld panyunguduke, hapana vaporization inofanira kuitika, iyo inowanzo shandiswa mukukwevera zvinhu zvinokurumidza zvishoma. Kukwevera nepakati kunopisa kunoita kuti chinhu chive neutsi uye kugadzire huwandu hwakawanda hweplasma. Nekuda kwekupisa kwakanyanya, pachava nemaburi pamberi pedziva rakanyungudutswa. Kukwevera nepakati pemvura ndiyo nzira inonyanya kushandiswa nelaser welding, inogona kukwevera nepakati pepabasa zvakanaka, uye simba rekupinda rakakura, zvichiita kuti kukurumidze kukwevera nemoto.

Maitiro ekugadzirisa muLaser Welding

Kune zvakawanda zvinokanganisa kunaka kwe laser welding, zvakaita se power density, laser pulse waveform, defocusing, welding speed uye sarudzo ye assistant shielding gas.

Kuwanda kweSimba reLaser

Kuwanda kwesimba ndeimwe yemipimo yakakosha mukugadzirisa nelaser. Nekuwanda kwesimba, pamusoro pechinhu ichi unogona kupiswa kusvika pakufashaira mukati me microsecond, zvichikonzera kuwanda kwemhepo. Nokudaro, kuwanda kwesimba guru kunobatsira pakubvisa zvinhu zvakaita sekuboora, kucheka nekunyora. Kune simba shoma, zvinotora mamirisekonzi akati wandei kuti tembiricha yepamusoro isvike pakufashaira, uye pamberi pekupfava, pasi panosvika pakunyunguduka, zviri nyore kugadzira weld yakanaka yekunyunguduka. Nokudaro, muchimiro chekuputira nelaser conduction, huwandu hwesimba i104-106W/cm2.

Mafungu eLaser Pulse

Kuumbwa kwemhepo neLaser pulse waveform hakusi chete chinhu chakakosha chekusiyanisa kubviswa kwezvinhu kubva mukunyunguduka kwezvinhu, asiwo chinhu chakakosha chekuona huwandu uye mutengo wemidziyo yekugadzirisa. Kana danda reLaser rakasimba kwazvo rapfurwa pamusoro pechinhu, pamusoro pechinhu chacho pachava ne60 ~ 90% yesimba reLaser rinoratidzwa uye rinofungidzirwa kurasikirwa, kunyanya goridhe, sirivha, mhangura, aruminiyamu, titanium nezvimwe zvinhu zvine mwenje wakasimba uye kupisa nekukurumidza. Kuratidzwa kwesimbi kunosiyana nekufamba kwenguva panguva yekupisa neLaser. Kana tembiricha pamusoro pechinhu ichi yakwira kusvika panzvimbo yekunyunguduka, mwenje unodzikira nekukurumidza, uye kana pamusoro pacho pave mukunyunguduka, mwenje unogadzikana pane imwe kukosha.

Upamhi hweLaser Pulse

Upamhi hwepulse chinhu chakakosha pakupinza kwelaser nepulsed. Upamhi hwepulse hwaionekwa nekudzika kwekupinda uye nzvimbo inokanganiswa nekupisa. Upamhi hwepulse hwakareba, nzvimbo inokanganiswa nekupisa yakakura, uye kudzika kwekupinda kwacho kwaiwedzera nesimba rehafu yehupamhi hwepulse. Zvisinei, kuwedzera kweupamhi hwepulse kunoderedza simba repamusoro, saka kuwedzera kweupamhi hwepulse kunowanzo shandiswa pakupinza kupisa, zvichikonzera saizi yakafara uye isina kudzika, kunyanya yakakodzera kupinza mapurati matete uye makobvu. Zvisinei, simba repamusoro rakaderera rinoita kuti kupisa kuwedzere, uye chinhu chega chega chine upamhi hwepulse hwakakodzera hunowedzera kudzika kwekupinda.

Huwandu hweDefocus

Kuwelda neLaser kunowanzoda kubviswa kwefocus, nekuti simba repakati penzvimbo paLaser rakanyanya kukwira, izvo zviri nyore kupwanya zvinhu zvekuwelda mugomba. Kupararira kwesimba remagetsi kwakafanana muchikamu chimwe nechimwe kubva paLaser.

Kune nzira mbiri dze defocus:

Kubvisa pfungwa zvakanaka nezvakaipa. Kana focal plane iri pamusoro peworkpiece, inenge iri positive defocus; zvikasadaro, inenge iri negative defocus. Sekureva kwedzidziso ye geometric optics, kana daro riri pakati pe positive negative defocus planes ne welding plane rakaenzana, simba remagetsi riri pa plane rinoenderana rinenge rakafanana, asi kutaura zvazviri, chimiro che pool yakanyungudutswa chakasiyana. Kana iri negative defocus, kupinda kwakanyanya kunogona kuwanikwa, izvo zvine chekuita nekuumbwa kwe pool yakanyungudutswa.

Kumhanya Kwekushongedza

Kumhanya kwewelding kunosarudza kunaka kwenzvimbo yekuwelding, kudzika kwekupinda, nzvimbo inokanganiswa nekupisa nezvimwewo. Kumhanya kwewelding kunokanganisa kupisa kunopinda panguva imwe neimwe. Kana kumhanya kwewelding kuchinonoka, kupisa kunopinda kwakanyanya, zvichiita kuti workpiece ipfute. Kana kumhanya kwewelding kuchikurumidza, kupisa kunopinda kushoma, zvichikonzera kuti workpiece ipinde zvishoma uye isina kupera. Kuderedza kumhanya kwewelding kunowanzo shandiswa kuvandudza kupinda kwechinhu.

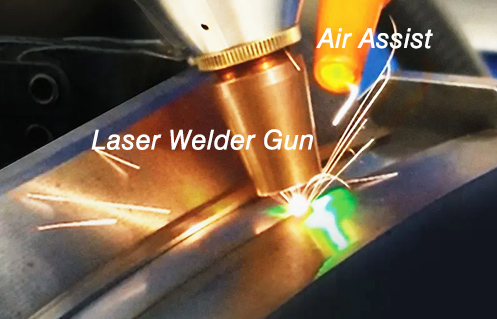

Gasi rekudzivirira rekubatsira

Gasi rekudzivirira kupwanya ndiro basa rakakosha mukubatanidza nelaser rine simba guru. Kune rumwe rutivi, kudzivirira zvinhu zvesimbi kuti zvisasvibise uye kusvibisa girazi rinotarisisa; Kune rumwe rutivi, kudzivirira plasma inogadzirwa mukubatanidza kuti isanyanya kutarisisa uye kudzivirira laser kuti isasvike pamusoro pechinhu chacho. Mukubatanidza nelaser, helium, argon, nitrogen nemamwe magasi anowanzo shandiswa kuchengetedza dziva rakanyungudutswa, kuitira kudzivirira workpiece kubva mukuoxidation muinjiniya yekubatanidza. Zvinhu zvakaita serudzi rwegasi rinodzivirira, saizi yemhepo inoyerera uye Angle inoputika zvine simba guru pamhedzisiro yekubatanidza, uye nzira dzakasiyana dzekuputira dzinewo simba rakati pamhando yekubatanidza.

Welder yeLaser inobatwa nemaoko inokurudzirwa nesu:

Laser Welder - Nzvimbo Yekushanda

◾ Tembiricha yenzvimbo yekushanda: 15~35 ℃

◾ Hunyoro hwenzvimbo yekushandira: < 70% Hapana kunyorova

◾ Kutonhodza: chitofu chemvura chinodiwa nekuda kwebasa rekubvisa kupisa kwezvinhu zvinobvisa kupisa nelaser, zvichiita kuti laser welder ishande zvakanaka.

(Mashandisirwo akadzama uye gwara rekushandisa chiller chemvura, unogona kutarisa:Matanho ekudzivirira kutonhora kweCO2 Laser System)

Unoda Kuziva Zvakawanda Nezve Laser Welders?

Nguva yekutumira: Zvita-22-2022