Yintoni ukuwelda nge-laser? Icacisiwe nge-Laser Welding! Konke okufuneka ukwazi malunga nokuwelda nge-laser, kuquka imigaqo ephambili kunye neeparamitha eziphambili zenkqubo!

Abathengi abaninzi abayiqondi imigaqo esisiseko yokusebenza komatshini wokuwelda nge-laser, ingasathethwa ke ngokukhetha umatshini wokuwelda nge-laser ofanelekileyo, nangona kunjalo iMimowork Laser ilapha ukukunceda wenze isigqibo esifanelekileyo kwaye inike inkxaso eyongezelelweyo ukukunceda ekuqondeni ukuwelda nge-laser.

Yintoni iLaser Welding?

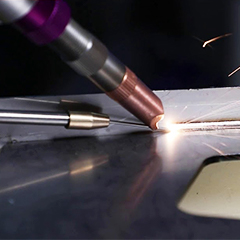

Ukuwelda nge-laser luhlobo lokuwelda ngokunyibilikisa, kusetyenziswa umqadi we-laser njengomthombo wobushushu bokuwelda, umgaqo wokuwelda kukuba indlela ethile yokuvuselela i-medium esebenzayo, yenze i-resonant cavity oscillation, ize iguqulwe ibe ngumqadi wemitha ovuselelweyo, xa umqadi kunye nenxalenye yomsebenzi zidibana, amandla afunxwa yinxalenye yomsebenzi, xa ubushushu bufikelela kwinqanaba lokunyibilikisa kwezinto zinokuwelda.

Ngokwendlela ephambili yokuwelda ichibi, ukuwelda nge-laser kuneendlela ezimbini ezisisiseko zokuwelda: ukuwelda kokuqhuba ubushushu kunye nokuwelda kokungena nzulu (i-keyhole). Ubushushu obuveliswa kukuwelda kokuqhuba ubushushu busasazwa kwindawo yokusebenza ngokudluliselwa kobushushu, ukuze umphezulu wokuwelda unyibilike, kungabikho mphunga owenzekayo, odla ngokusetyenziswa ekuweldaniseni izinto ezincinci ezinesantya esiphantsi. Ukuwelda kwe-deep fusion kuyawufumisa loo mbandela kwaye kwenze inani elikhulu le-plasma. Ngenxa yobushushu obuphezulu, kuya kubakho imingxunya ngaphambili kwechibi elinyibilikisiweyo. Ukuwelda kwe-deep penetration yeyona ndlela yokuwelda ye-laser esetyenziswa kakhulu, inokuwelda kakuhle into yokusebenza, kwaye amandla okufaka makhulu, nto leyo ekhokelela kwisantya sokuwelda esikhawulezayo.

Iiparameter zeNkqubo kwi-Laser Welding

Kukho iiparameter ezininzi zenkqubo ezichaphazela umgangatho wokuwelda nge-laser, ezifana noxinano lwamandla, i-laser pulse waveform, i-defocusing, isantya sokuwelda kunye nokukhetha igesi yokukhusela encedisayo.

Uxinano lwamandla eLaser

Uxinano lwamandla yenye yezona parameter zibalulekileyo ekucutshungulweni kwelaser. Ngoxinano lwamandla aphezulu, umaleko womphezulu unokufudunyezwa uye kwinqanaba lokubila ngaphakathi kwe-microsecond, nto leyo ebangela ukuba kubekho umphunga omninzi. Ke ngoko, uxinano lwamandla aphezulu luluncedo kwiinkqubo zokususa izinto ezifana nokubhola, ukusika kunye nokukrola. Uxinano lwamandla aphantsi, kuthatha ii-milliseconds ezininzi ukuze ubushushu bomphezulu bufikelele kwinqanaba lokubila, kwaye ngaphambi kokuba umphezulu ube ngumphunga, umzantsi ufikelela kwinqanaba lokunyibilika, okulula ukwenza i-weld elungileyo yokunyibilika. Ke ngoko, ngendlela ye-welding ye-laser yokuqhuba ubushushu, uluhlu lwamandla oxinano luyi-104-106W/cm2.

Ifomu yeLaser Pulse Waveform

I-laser pulse waveform ayisiyonto ibalulekileyo nje kuphela yokwahlula ukususwa kwezinto ekunyibilikeni kwezinto, kodwa ikwayiyonto iphambili yokumisela ubungakanani kunye neendleko zezixhobo zokucubungula. Xa umqadi we-laser onamandla aphezulu udutshulwa kumphezulu wezinto, umphezulu wezinto uya kuba ne-60 ~ 90% yamandla e-laser abonakalisiweyo kwaye acingelwa ukuba alahlekile, ingakumbi igolide, isilivere, ubhedu, i-aluminium, i-titanium kunye nezinye izinto ezinokukhanya okunamandla kunye nokudluliselwa kobushushu ngokukhawuleza. Ukukhanya kwesinyithi kuyahluka ngokuhamba kwexesha ngexesha lokukhanya kwe-laser. Xa ubushushu bomphezulu wezinto bunyuka bufikelela kwinqanaba lokunyibilika, ukukhanya kwehla ngokukhawuleza, kwaye xa umphezulu ukwimeko yokunyibilika, ukukhanya kuzinza ngexabiso elithile.

Ububanzi beLaser Pulse

Ububanzi bepulse yiparameter ebalulekileyo yokuwelda nge-laser eshukumayo. Ububanzi bepulse bumiselwe bubunzulu bokungena kunye nendawo echaphazelekileyo bubushushu. Okukhona ububanzi bepulse bude, kokukhona indawo echaphazelekileyo bubushushu inkulu, kwaye ubunzulu bokungena buyanda ngamandla ayi-1/2 yobubanzi bepulse. Nangona kunjalo, ukwanda kobubanzi bepulse kuya kunciphisa amandla encochoyi, ngoko ke ukwanda kobubanzi bepulse kudla ngokusetyenziselwa ukuwelda ngobushushu, okubangela ubungakanani be-weld ebanzi nenganzulu, ngakumbi efanelekileyo ekuwelda kwe-lap yeeplate ezincinci nezityebileyo. Nangona kunjalo, amandla encochoyi aphantsi abangela ukufakelwa kobushushu obuninzi, kwaye isixhobo ngasinye sinobubanzi bepulse obufanelekileyo okwandisa ubunzulu bokungena.

Ubungakanani bokuCima iFocus

Ukuwelda nge-laser kudla ngokufuna umlinganiselo othile wokungajolisi, kuba uxinano lwamandla lwendawo ephakathi kwindawo egxile kuyo i-laser luphezulu kakhulu, nto leyo elula ukuyikhupha ibe yimingxuma. Ukusasazwa koxinano lwamandla kuyafana kwiplanga ngalinye kude nendawo egxile kuyo i-laser.

Kukho iindlela ezimbini ze-defocus:

Ukufocus okulungileyo nokungalunganga. Ukuba i-focal plane ikwindawo engaphezulu kwe-workpiece, i-positive defocus; kungenjalo, i-negative defocus. Ngokwethiyori ye-geometric optics, xa umgama phakathi kwe-positive kunye ne-negative defocus planes kunye ne-welding plane ulingana, uxinano lwamandla kwi-plane ehambelanayo luphantse lufane, kodwa eneneni, imo ye-metal pool efunyenweyo yahlukile. Kwimeko ye-negative defocus, ukungena okukhulu kunokufumaneka, okunxulumene nenkqubo yokwakheka kwe-metal pool.

Isantya sokuWelda

Isantya sokuwelda simisela umgangatho womphezulu wokuwelda, ubunzulu bokungena, indawo echaphazelekileyo bubushushu njl.njl. Isantya sokuwelda siya kuchaphazela igalelo lobushushu ngexesha ngalinye. Ukuba isantya sokuwelda sicotha kakhulu, igalelo lobushushu liphezulu kakhulu, nto leyo ebangela ukuba i-workpiece itshise. Ukuba isantya sokuwelda sikhawuleza kakhulu, igalelo lobushushu lincinci kakhulu, nto leyo ebangela ukuba i-workpiece iwelding ingaphelelanga kwaye ingagqitywanga. Ukunciphisa isantya sokuwelda kudla ngokusetyenziselwa ukuphucula ukungena.

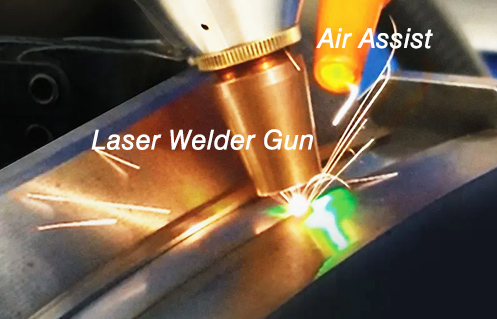

Igesi yoKhuseleko oluNcedisayo

Igesi yokukhusela ukuvuthela yinkqubo ebalulekileyo kwi-laser welding enamandla aphezulu. Kwelinye icala, ukuthintela izinto zesinyithi ukuba zingatshizi kwaye zingcolise isibuko esijolisa; Kwelinye icala, kukuthintela iplasma eveliswa kwinkqubo ye-welding ukuba ingagxili kakhulu kwaye kuthintele i-laser ukuba ingafiki kumphezulu wezinto. Kwinkqubo ye-laser welding, i-helium, i-argon, i-nitrogen kunye nezinye iigesi zihlala zisetyenziselwa ukukhusela ichibi elinyibilikisiweyo, ukuze kuthintelwe i-workpiece kwi-oxidation kubunjineli be-welding. Izinto ezifana nohlobo lwegesi ekhuselayo, ubungakanani bokuhamba komoya kunye ne-Angle evuthelayo zinempembelelo enkulu kwiziphumo ze-welding, kwaye iindlela ezahlukeneyo zokuvuthela nazo ziya kuba nempembelelo ethile kumgangatho we-welding.

Isishicileli sethu seLaser esiphathwa ngesandla esicetyiswayo:

Umthungi weLaser - Indawo yokusebenzela

◾ Uluhlu lobushushu kwindawo yokusebenza: 15~35 ℃

◾ Uluhlu lomswakama kwindawo yokusebenza: < 70% Akukho kufuma

◾ Ukupholisa: i-water chiller iyimfuneko ngenxa yomsebenzi wokususa ubushushu kwiindawo ezichitha ubushushu nge-laser, ukuqinisekisa ukuba i-laser welder isebenza kakuhle.

(Ukusetyenziswa okuneenkcukacha kunye nesikhokelo malunga nesixhobo sokupholisa amanzi, ungajonga oku kulandelayo:Amanyathelo okuthintela ukuqandisa kwiNkqubo yeLaser yeCO2)

Ufuna ukwazi okungakumbi ngabaWelder beLaser?

Ixesha lokuthumela: Disemba-22-2022