Menene walda ta laser? Bayanin walda ta laser! Duk abin da kuke buƙatar sani game da walda ta laser, gami da mahimman ƙa'idodi da manyan sigogin tsari!

Abokan ciniki da yawa ba su fahimci ƙa'idodin aiki na injin walda na laser ba, balle a zaɓi injin walda na laser da ya dace, duk da haka Mimowork Laser yana nan don taimaka muku yanke shawara mai kyau da kuma samar da ƙarin tallafi don taimaka muku fahimtar walda na laser.

Menene walda ta Laser?

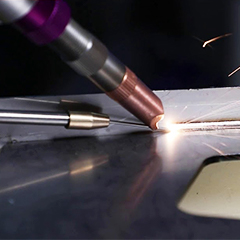

Walda ta Laser wani nau'in walda ne na narkewa, ta amfani da hasken laser a matsayin tushen zafi na walda, ƙa'idar walda ita ce wata hanya ta musamman don motsa matsakaici mai aiki, samar da sautin rami mai amsawa, sannan a canza zuwa hasken radiation mai motsawa, lokacin da hasken da aikin suka haɗu da juna, makamashin yana sha ta wurin aikin, lokacin da zafin jiki ya kai wurin narkewar kayan za a iya walda shi.

A bisa ga babban tsarin walda, walda ta laser tana da manyan hanyoyin walda guda biyu: walda mai isar da zafi da walda mai shiga zurfin rami (maɓalli). Zafin da walda mai isar da zafi ke samarwa yana yaɗuwa zuwa wurin aiki ta hanyar canja wurin zafi, don haka saman walda ya narke, bai kamata a sami tururi ba, wanda galibi ana amfani da shi a cikin walda na ƙananan sassa masu sirara. Walda mai haɗuwa mai zurfi yana tururi kayan kuma yana samar da babban adadin plasma. Saboda zafi mai yawa, za a sami ramuka a gaban tafkin narkakken. Walda mai shiga zurfin rami shine yanayin walda ta laser da aka fi amfani da shi, yana iya walda aikin sosai, kuma kuzarin shigarwa yana da girma, wanda ke haifar da saurin walda.

Sigogi na Tsarin Aiki a Walda ta Laser

Akwai sigogi da yawa na tsari waɗanda ke shafar ingancin walda na laser, kamar yawan wutar lantarki, yanayin bugun zuciya na laser, cire hankali, saurin walda da zaɓin iskar gas mai kariya ta taimako.

Yawan ƙarfin Laser

Yawan ƙarfi yana ɗaya daga cikin mahimman sigogi a cikin sarrafa laser. Tare da yawan ƙarfi mai yawa, ana iya dumama saman Layer zuwa wurin tafasa a cikin microsecond, wanda ke haifar da yawan tururi mai yawa. Saboda haka, yawan ƙarfi mai yawa yana da amfani ga hanyoyin cire kayan kamar haƙa, yankewa da sassaka. Don ƙarancin yawan ƙarfi, yana ɗaukar milliseconds da yawa kafin zafin saman ya isa wurin tafasa, kuma kafin saman ya yi tururi, ƙasan ya isa wurin narkewa, wanda yake da sauƙin samar da walda mai kyau. Saboda haka, a cikin nau'in walda laser mai ɗaukar zafi, kewayon yawan ƙarfin shine 104-106W/cm2.

Tsarin Laser Pulse

Tsarin bugun Laser ba wai kawai muhimmin siga bane don bambance cire kayan daga narkewar abu, har ma da mahimmin siga don tantance girma da farashin kayan aiki. Lokacin da aka harba hasken laser mai ƙarfi zuwa saman kayan, saman kayan zai sami kashi 60 ~ 90% na kuzarin laser da aka nuna kuma aka yi la'akari da shi asara, musamman zinare, azurfa, jan ƙarfe, aluminum, titanium da sauran kayan da ke da ƙarfin haske da canja wurin zafi cikin sauri. Hasken ƙarfe yana canzawa tare da lokaci yayin bugun laser. Lokacin da zafin saman kayan ya tashi zuwa wurin narkewa, haskakawa yana raguwa da sauri, kuma lokacin da saman yake cikin yanayin narkewa, haskakawa yana daidaita a wani ƙima.

Faɗin bugun Laser

Faɗin bugun jini muhimmin ma'auni ne na walda mai amfani da laser. An ƙayyade faɗin bugun jini ta hanyar zurfin shigar ciki da yankin da zafi ya shafa. Tsawon faɗin bugun jini ya yi, girman yankin da zafi ya shafa ya yi, kuma zurfin shigar ya ƙaru da ƙarfin 1/2 na faɗin bugun jini. Duk da haka, ƙaruwar faɗin bugun jini zai rage ƙarfin kololuwa, don haka ana amfani da ƙaruwar faɗin bugun jini gabaɗaya don walda mai isar da zafi, wanda ke haifar da girman walda mai faɗi da mara zurfi, musamman dacewa da walda mai laushi da faranti masu kauri. Duk da haka, ƙarancin ƙarfin kololuwa yana haifar da shigar zafi mai yawa, kuma kowane abu yana da faɗin bugun jini mafi kyau wanda ke haɓaka zurfin shigar ciki.

Yawan Rage Focus

Walda ta laser yawanci tana buƙatar ɗan rage ƙarfin haske, saboda ƙarfin da ke tsakiyar wurin da ke mayar da hankali kan laser ya yi yawa, wanda hakan ke sa kayan walda su yi tauri cikin ramuka. Rarraba yawan wutar lantarki iri ɗaya ne a kowane wuri nesa da mayar da hankali kan laser.

Akwai hanyoyi biyu na defocus:

Defocus mai kyau da mara kyau. Idan focal plane yana saman workpiece, defocus mai kyau ne; in ba haka ba, defocus mai kyau ne. A cewar ka'idar gani na geometric, lokacin da nisan da ke tsakanin jiragen defocus mai kyau da mara kyau da jirgin walda ya yi daidai, yawan ƙarfin da ke kan jirgin da ya dace kusan iri ɗaya ne, amma a zahiri, siffar wurin waha da aka samu ta bambanta. Idan aka sami defocus mai kyau, ana iya samun ƙarin shigar ciki, wanda ke da alaƙa da tsarin samuwar wurin waha da aka narke.

Gudun Walda

Gudun walda yana ƙayyade ingancin saman walda, zurfin shigar ciki, yankin da zafi ya shafa da sauransu. Gudun walda zai shafi shigar zafi a kowane lokaci na naúra. Idan saurin walda ya yi jinkiri sosai, shigar zafi ya yi yawa, wanda ke haifar da ƙonewar kayan aikin. Idan saurin walda ya yi sauri sosai, shigar zafi ya yi ƙasa, wanda ke haifar da walda na kayan aikin a wani ɓangare kuma ba a gama ba. Rage saurin walda yawanci ana amfani da shi don inganta shigar.

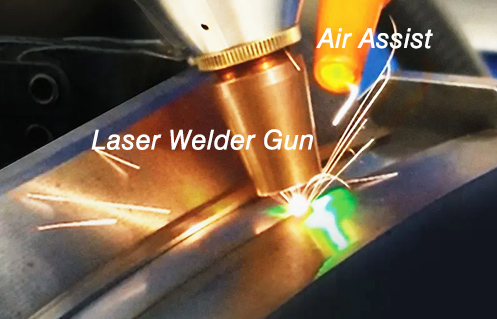

Iskar Gas Mai Kariya ta Ƙarfi

Iskar gas mai kariya daga buguwa ta taimako hanya ce mai mahimmanci a walda mai ƙarfin laser mai ƙarfi. A gefe guda, don hana kayan ƙarfe su toka da kuma gurɓata madubin mai mai da hankali; A gefe guda kuma, don hana plasma da aka samar a cikin walda ya mayar da hankali sosai da kuma hana laser isa saman kayan. A cikin walda ta laser, ana amfani da helium, argon, nitrogen da sauran iskar gas sau da yawa don kare wurin narkewar narkewa, don hana aikin daga iskar shaka a cikin injiniyan walda. Abubuwa kamar nau'in iskar gas mai kariya, girman kwararar iska da kusurwar busawa suna da babban tasiri akan sakamakon walda, kuma hanyoyin busawa daban-daban suma za su yi tasiri kan ingancin walda.

Na'urar walda ta Laser ta hannu da muke ba da shawarar:

Mai walda na Laser - Muhalli na Aiki

◾ Yanayin zafin jiki na wurin aiki: 15~35 ℃

◾ Yanayin zafi na yanayin aiki: < 70% Babu danshi

◾ Sanyaya: na'urar sanyaya ruwa tana da mahimmanci saboda aikin cire zafi ga abubuwan da ke fitar da zafi daga laser, wanda ke tabbatar da cewa na'urar sanyaya laser tana aiki yadda ya kamata.

(Cikakken bayani game da amfani da na'urar sanyaya ruwa, zaku iya duba:Matakan Kare Daskararru don Tsarin Laser na CO2)

Shin kuna son ƙarin bayani game da na'urorin walda na Laser?

Lokacin Saƙo: Disamba-22-2022