Ha u le ncha ho theknoloji ea laser 'me u nahane ka ho reka mochine oa ho itšeha ka laser, ho tlameha ho ba le lipotso tse ngata tseo u batlang ho li botsa.

MimoWork ke thabela ho arolelana le uena lintlha tse ling mabapi le mechini ea laser ea CO2, 'me re tšepa hore u ka fumana sesebelisoa se u loketseng hantle, ekaba se tsoa ho rona kapa morekisi e mong oa laser.

Sehloohong sena, re tla fana ka kakaretso e khuts'oane ea ho hlophisoa ha mochini ho tloaelehileng le ho etsa tlhahlobo ea papiso ea lekala ka leng. Ka kakaretso, sengoloa se tla akaretsa lintlha tse latelang:

>> Sebopeho sa Mechanical mochini oa laser

>> CO2 khalase laser tubes VS CO2 RF laser tubes (Synrad, Coherent, Rofin)

>> Laola Sisteme le Software

>> Dikgetho

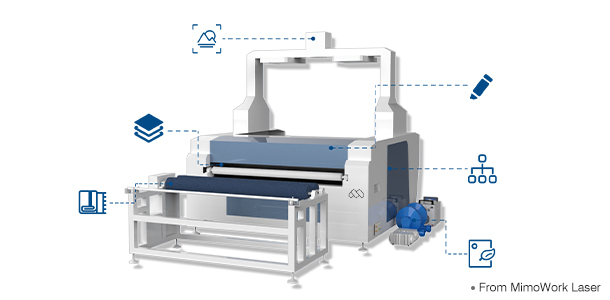

Mechanics ea mochini oa laser CO2

a. Brushless DC Motor, Servo Motor, Step Motor

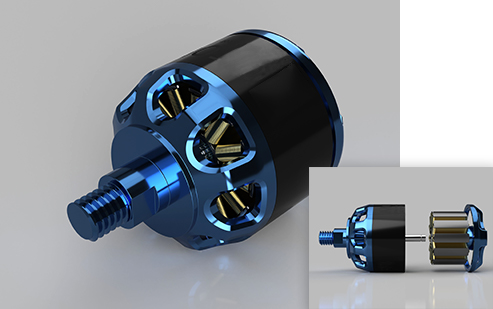

Brushless DC (ho toba hona joale) motlakase

Brushless DC motor e ka matha ka RPM e phahameng (liphetoho ka motsotso). Stator ea koloi ea DC e fana ka matla a khoheli a potolohang a khannang armature ho potoloha. Har'a likoloi tsohle, brushless dc motor e ka fana ka matla a matla a kinetic le ho khanna hlooho ea laser ho tsamaea ka lebelo le leholo.Mochini o betliloeng oa laser oa MimoWork o motle ka ho fetisisa oa CO2 e na le enjene e se nang brush mme e ka fihlela lebelo le holimo la ho betla la 2000mm/s.Enjene ea brushless dc ha e bonahale hangata mochining oa ho itšeha oa laser oa CO2. Sena se bakoa ke hore lebelo la ho khaola ka thepa le lekanyelitsoe ke botenya ba thepa. Ho fapana le hoo, o hloka feela matla a manyane a ho betla lits'oants'o lisebelisoa tsa hau, Enjene ea brushless e nang le mochini oa engraver oa laser e tla khutsufatsa nako ea hau ea ho betla ka mokhoa o nepahetseng haholoanyane.

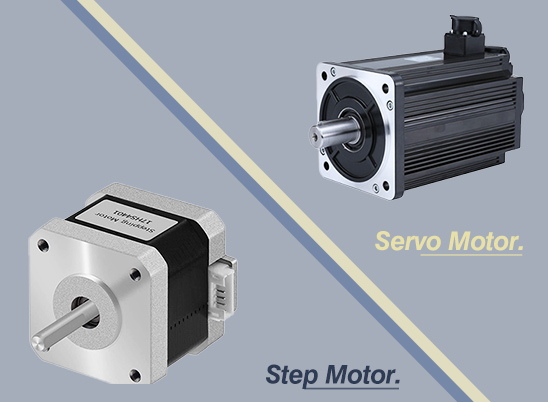

Servo motor & Step motor

Joalo ka ha bohle re tseba taba ea hore li-servo motors li ka fana ka maemo a holimo a torque ka lebelo le holimo mme li theko e boima ho feta li-motor tsa stepper. Li-motors tsa servo li hloka encoder ho fetola maqhubu bakeng sa taolo ea boemo. Tlhokahalo ea encoder le gearbox e etsa hore sistimi e rarahane haholoanyane, e lebisang tlhokomelong khafetsa le litšenyehelo tse phahameng. E kopantsoe le mochini oa laser oa CO2,Enjene ea servo e ka fana ka ho nepahala ho holimo ho boemo ba gantry le hlooho ea laser ho feta koloi ea stepper e etsang. Athe, ho bua 'nete, hangata, ho thata ho bolela phapang ea ho nepahala ha u sebelisa li-motor tse fapaneng, haholo-holo haeba u etsa limpho tse bonolo tse sa hlokeng ho nepahala ho hongata. Haeba o ntse o sebetsana le lisebelisoa tse kopaneng le lits'ebetso tsa tekheniki, joalo ka lesela la filthara bakeng sa poleiti ea filthara, lesira le sireletsehileng la koloi bakeng sa koloi, sekoaelo se sireletsang mokhanni, joale bokhoni ba li-motors tsa servo bo tla bonts'oa hantle.

Enjene ka 'ngoe e na le melemo le mathata a eona. E u tšoanelang ke eona e molemohali ho uena.

Ka sebele, MimoWork e ka fana ka Moetsi oa laser oa CO2 le sehahi e nang le mefuta e meraro ea enjene ho ipapisitsoe le tlhoko ea hau le tekanyetso ea hau.

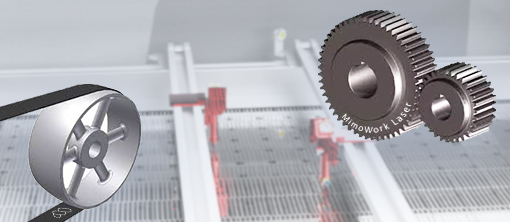

b. Belt Drive VS Gear Drive

Belt drive ke mokhoa oa ho hokahanya mabili ka lebanta athe gear drive ke likere tse peli tse hokahaneng joalo ka ha meno ka bobeli a hokahane. Ka sebopeho sa mochini oa lisebelisoa tsa laser, li-drive ka bobeli li sebelisoa holaola motsamao oa laser gantry le ho hlalosa ho nepahala ha mochine oa laser.

Ha re bapise tse peli le tafole e latelang:

|

Belt Drive |

Gear Drive |

| Lintho tse ka sehloohong tsa Pulleys le Belt | Lintho tse ka sehloohong Gears |

| Ho hlokahala sebaka se eketsehileng | Sebaka se fokolang se hlokahalang, ka hona mochine oa laser o ka etsoa hore o be o monyenyane |

| Tahlehelo e phahameng ea likhohlano, ka hona phetisetso e tlase le ts'ebetso e fokolang | Tahlehelo e tlase ea likhohlano, ka hona phetisetso e phahameng le ts'ebetso e eketsehileng |

| Tebello ea bophelo e tlase ho feta likoloi tsa likoloi, hangata e fetoha lilemo tse ling le tse ling tse 3 | Tebello ea bophelo e kholo haholo ho feta ho khanna mabanta, hangata e fetoha lilemo tse leshome |

| E hloka tlhokomelo e eketsehileng, empa litšenyehelo tsa tlhokomelo li batla li le tlaase ebile li bonolo | E hloka tlhokomelo e fokolang, empa litšenyehelo tsa tlhokomelo li batla li le tlase ebile li boima |

| Lubrication ha e hlokehe | Hloka lubrication kamehla |

| Ho khutsitse haholo ts'ebetsong | Lerata ts'ebetsong |

Ka bobeli li-gear drive le litsamaiso tsa lebanta li atisa ho etsoa mochine oa ho itšeha oa laser o nang le melemo le boiketlo. Ke akaretsa feela,Sistimi ea ho khanna lebanta e na le molemo ho feta mefuteng e menyenyane, mefuta e fofang ea mochini; ka lebaka la phetiso e phahameng le ho tšoarella nako e telele,koloi ea li-gear e loketse haholoanyane bakeng sa sehahi sa laser se nang le sebopeho se seholo, hangata se nang le moralo oa hybrid optical.

c. Tafole ea Ts'ebetso ea Stationary VS Conveyor Working Table

Bakeng sa ho ntlafatsa ts'ebetso ea laser, o hloka ho feta phepelo ea laser ea boleng bo holimo le sistimi e ikhethang ea ho khanna ho tsamaisa hlooho ea laser, ho hlokahala tafole e loketseng ea tšehetso ea thepa. Tafole e sebetsang e etselitsoeng ho tsamaisana le thepa kapa ts'ebeliso e bolela hore o ka eketsa bokhoni ba mochini oa hau oa laser.

Ka kakaretso, ho na le mekhahlelo e 'meli ea li-platform tse sebetsang: Stationary le Mobile.

(Bakeng sa lits'ebetso tse fapaneng, u ka qetella u sebelisa mefuta eohle ea lisebelisoa tshebediso ya leshiti kapa thepa e phuthetsweng)

○ Tafole ea Ts'ebetso e Emeng e loketse ho beha lisebelisoa tsa pampiri tse kang acrylic, lehong, pampiri (cardboard).

• tafole ea ho hlobolisa thipa

• tafole ea mahe a linotši

○ Tafole e Sebetsang ea Conveyor e loketse ho beha lisebelisoa tsa moqolo joalo ka lesela, letlalo, foam.

• tafole ea shuttle

• tafole conveyor

Melemo ea moralo o loketseng oa tafole ea ho sebetsa

✔ Khatello e ntle ea tlhahiso ea likhahla

✔ Tsitsisa lintho tse bonahalang, ha ho displacement etsahala ha seha

✔ Ho bonolo ho kenya le ho laolla li-workpieces

✔ Tataiso e nepahetseng ea ho tsepamisa maikutlo ka lebaka la libaka tse bataletseng

✔ Tlhokomelo e bonolo le ho hloekisa

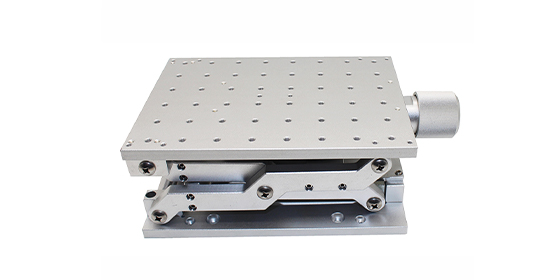

d. Mokhoa oa ho Phahamisa ka Othomathike oa VS Manual Lifting Platform

Ha u ntse u ngola thepa e tiileng, joalo ka acrylic (PMMA) le lehong (MDF), lisebelisoa li fapana ka botenya. Bophahamo bo nepahetseng bo ka ntlafatsa phello ea engraving. Sethala sa ho sebetsa se feto-fetohang sea hlokahala ho fumana ntlha e nyane haholo. Bakeng sa mochini o betliloeng oa laser oa CO2, liforomo tsa ho phahamisa othomathike le li-platform tsa ho phahamisa matsoho hangata li bapisoa. Haeba tekanyetso ea hau e lekane, e-ea bakeng sa li-platform tsa ho phahamisa ka mokhoa o itekanetseng.Eseng feela ho ntlafatsa ho itšeha le ho ngola ka nepo, ho ka u bolokela nako le boiteko.

e. Sistimi ea moea e kaholimo, e ka tlase le e ka tlase

Sistimi e tlase ea moea ke khetho e atileng haholo ea mochini oa laser oa CO2, empa MimoWork e boetse e na le mefuta e meng ea moralo ho ntšetsa pele boiphihlelo bohle ba ts'ebetso ea laser. Bakeng sa amochini o sehang oa laser o boholo bo boholo, MimoWork e tla sebelisa e kopantsoeng tsamaiso ea ho qeta holimo le tlaseho matlafatsa phello ea ho ntša ha u ntse u boloka liphetho tsa boleng bo holimo tsa laser. Bakeng sa ba bangata ba ronamochini oa ho tšoaea oa galvo, re tla kenya tsamaiso ea moea e ka mahlakorengho ntsha mosi. Lintlha tsohle tsa mochini li lokela ho lebisoa hamolemo ho rarolla mathata a indasteri ka 'ngoe.

An tsamaiso ea ho ntšae hlahisoa ka tlas'a thepa e etsoang ka mochine. Hase feela ho ntša mosi o hlahisoang ke phekolo ea mocheso empa hape o tsitsisa lisebelisoa, haholo-holo lesela le boima bo bobebe. Ha karolo e kholo ea sebaka sa ts'ebetso e koahetsoeng ke thepa e ntseng e sebetsoa, e phahameng ke phello ea ho hula le vacuum e hlahisoang.

CO2 khalase laser tubes VS CO2 RF laser tubes

a. Brushless DC Motor, Servo Motor, Step Motor

Lipotso tse ling mabapi le mochini oa laser kapa tlhokomelo ea laser

Nako ea poso: Oct-12-2021