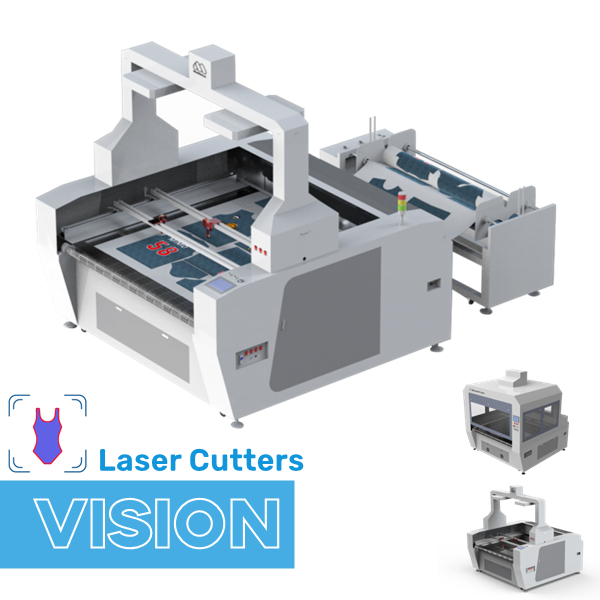

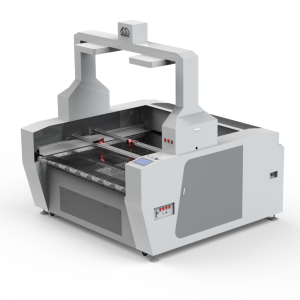

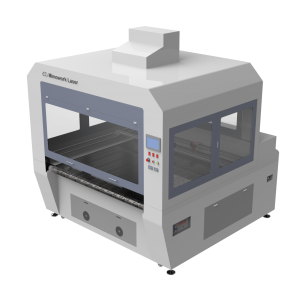

Vision Laser Cutting Machine

Technical Data

* Vision Laser Cutter 180L has the same Working Area and Max Material Width as Vision Laser Cutter Fully-Enclosed

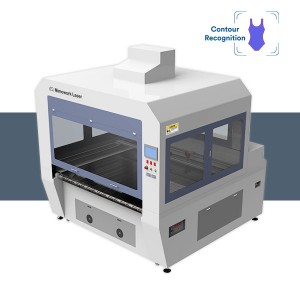

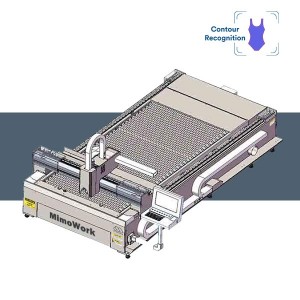

| Working Area (W *L) | 1600mm * 1200mm (62.9” * 47.2”) - 160L |

| 1800mm * 1300mm (70.87’’ * 51.18’’) - 180L | |

| Max Material Width | 1600mm / 62.9” - 160L |

| 1800mm / 70.87’’ - 180L | |

| Laser Power | 100W/ 130W/ 300W |

| Laser Source | CO2 Glass Laser Tube / RF Metal Tube |

| Mechanical Control System | Belt Transmission & Servo Motor Drive |

| Working Table | Mild Steel Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* All Three Vision Laser Cutters have a Dual Laser Head Upgrade Option Available

Advantages of Vision Laser Cutters - Wider the Creativity, Better the Performance

Changing the Industry with Vision Cuts

▶ Widely used in Digital Printing Products like advertising banners, clothing, home textiles, and other industries

▶ Thanks to MimoWork's latest innovative technology, our customers can realize efficient production with Fast & Accurate Laser Cutting of dye sublimation textiles, which helps your products to respond to market needs quickly

▶ Advanced Visual Recognition Technology and powerful software provide Higher Quality & Reliability for your production

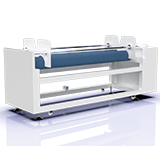

▶ The Automatic Feeding System and the conveying work platform work together to achieve an Automatic Roll-to-Roll Processing Process, saving labor and improving efficiency, it also allows unattended operation which saves your labor cost and lowers the rejection rate (Optional)

Multifunction of Vision Laser Machine

Large Working Table

Independent Dual Heads - Optional Upgrades

of Laser Cutting Sublimation Leggings

of Elastic Fabric Laser Cutting

of How to Laser Cut Flag with HD Camera

of Enclosed Vision Laser Cutter

Find more videos about our laser cutters at our Video Gallery

Having any Question about How the Vision Laser Cutter Works?

Fields of Application

for Vision Laser Cutting Machines

Excellent Cutting Quality in Laser Cutting Signs, Flag, Banner

✔ Significantly reduce the working time for orders in short delivery time

✔ The actual position and dimensions of the the work piece can be recognized exactly

✔ No material distortion thanks to the stress-free material feed and contact-less cutting

✔ Ideal cutter for making exhibition stands, banners, display systems, or visual protection

Clean and Smooth Edge with Thermal Treatment

✔ High-cutting quality, accurate pattern recognition, and fast production

✔ Meeting the needs of small-patch production for local sports team

✔ Combination tool with your Calendar Heat Press

✔ No need for cutting file

Excellent Cutting Quality with More to Spare

✔ The HD camera enables continuous and precise cutting of sublimated textiles with intricate designs and patterns.

✔ Faster and more efficient cutting, reducing production time and costs.

✔ With the ability to detect pattern outlines, allows for more intricate and detailed designs to be cut with ease.

✔ Produces minimal waste, resulting in cost savings and a more sustainable production process.

✔ HD cameras can handle a wide range of materials, making them suitable for various industries and applications.

✔ Customizable working platforms and adjusting laser settings ensure that the vision laser cutter can be tailored to specific needs and preferences.

Materials: Polyester Fabric, Spandex, Nylon, Silk, Printed Velvet, Cotton, and other sublimation textiles

Applications: Active Wear, Sportswear (Cycling Wear, Hockey Jerseys, Baseball Jerseys, Basketball Jerseys, Soccer Jerseys, Volleyball Jerseys, Lacrosse Jerseys, Ringette Jerseys), Uniforms, Swimwear, Leggings, Sublimation Accessories (Arm Sleeves, Leg Sleeves, Bandanna, Headband, Face Cover, Masks)

Materials: Polyester, Spandex, Lycra, Silk, Nylon, Cotton and other sublimation fabrics

Applications: Sublimation Accessories (Pillow), Rally Pennants, Flag, Signage, Billboard, Swimwear, Leggings, Sportswear, Uniforms

Materials: Polyester Fabric, Spandex, Cotton, Silk, Printed Velvet, Film and other Sublimation Materials

Application: Rally Pennants, Banner, Billboard, Teardrop Flag, Leggings, Sportswear, Uniforms, Swimwear