Film Laser Cutter 160 with conveyor table

We thinks what clients think, the urgency of urgency to act inside the interests of a customer position of basic principle, allowing for much better high quality, reduce processing costs, charges are additional reasonable, won the new and previous customers the support and affirmation for Film Laser Cutter 160 with conveyor table, The concept of our organization is “Sincerity, Speed, Provider, and Satisfaction”. We are going to follow this concept and earn more and more customers’ satisfaction.

We thinks what clients think, the urgency of urgency to act inside the interests of a customer position of basic principle, allowing for much better high quality, reduce processing costs, charges are additional reasonable, won the new and previous customers the support and affirmation for 3M film laser cutting, film laser cutter, film laser cutting, film laser cutting machine, film laser engraver, Flatbed Laser Cutter, Flatbed Laser Cutter Machine, Flatbed Laser Cutting Machine, Flatbed Laser Engraver, laser cut adhesive film, laser cut polyester film, laser cut window film, laser cutter for film, laser cutting films for keyboards, laser cutting for PVC film, laser cutting heat transfer film, laser cutting of protective films, pet film laser cutting, plastic film laser cutting, polyester film laser cutting, printed film, printed vinyl film cutting, vinyl film wrap laser cut, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

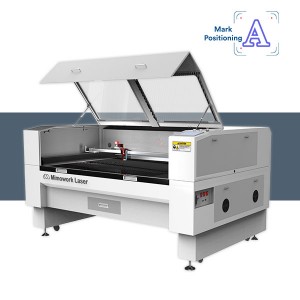

Advantages of Textile Laser Cutter Machine

A Giant Leap in Productivity

◉ Flexible & quick cutting:

Flexible and fast MimoWork laser cutting technology helps your products quickly respond to market needs

◉ Popular size for multiple materials:

Standard 1600mm * 1000mm is accord with most materials formats like fabric and leather (working size can be customized)

◉ Safe and stable laser structure:

Upgraded cutting stability and safety – improved by adding the vacuum suction function

◉ Automatic production – less labor:

Automatic feeding and conveying allow unattended operation which saves your labor cost, lower rejection rate (optional)

Mark pen makes labor-saving process and efficient cutting and materials labeling operations possible

Technical Data

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

* Servo Motor Upgrade Available

(As your garment laser cutter, leather laser cutter, lace laser cutter)

R&D for Laser Cutting Fabric

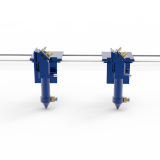

Two / Four / Multiple Laser Heads

In the simplest and most economic way to speed up your production efficiency is to mount multiple laser heads on the same gantry and cut the same pattern simultaneously. This doesn’t take extra space or labor. If you need to cut a lot of identical patterns, this would be a perfect choice for you.

Nesting Software

When you are trying to cut a whole lot of different designs and want to save material to the largest degree, the Nesting Software will be a good choice for you. By selecting all the patterns you want to cut and setting the numbers of each piece, the software will nest these pieces with the most usage rate to save your cutting time and roll materials. Simply send the nesting markers to the Flatbed Laser Cutter 160, it will cut uninterruptedly without any further manual intervention.

Auto Feeding System

The Auto Feeder combined with the Conveyor Table is the ideal solution for series and mass production. It transports the flexible material (fabric most of the time) from the roll to the cutting process on the laser system. With stress-free material feeding, there is no material distortion while contactless cutting with laser ensures outstanding results.

Customize Your Laser Cutter Machine

MimoWork is here to help you with laser advice!

Video Display of Textile Laser Cutting

Dual Heads Laser Cutting on Denim

• With the help of auto-feeder and conveyor system, the roll fabric can be fast conveyed to the laser table and making preparation for the laser cutting. Automatic process greatly enhance the efficiency and lessen the labor cost.

• And the versatile laser beam features excellent the penetration power through the fabrics (textiles), allowing the flat and clean cutting quality in short time.

Details Explanation

you can see the smooth and crisp cutting edge without any burr. That is incomparable with the traditional knife cutting. Non-contact laser cutting ensures being intact and undamaged for both fabric and laser head. Convenient & safe laser cutting becomes ideal choice for the apparel, sportswear equipment, home textiles manufacturers.

Related Links:

>> Denim Laser Cutting & Engraving

Fields of Application

Laser Cutting for Your Industry

Common materials and applications

of Flatbed Laser Cutter 160

Materials: Fabric, Leather, Cotton, Nylon, Film, Foil, Foam, Spacer Fabric, and other Composite Materials

Applications: Footwear, Plush Toys, Garment, Fashion, Garment Accessories, Filter Media, Airbag, Fabric Duct, Car Seat, etc.

>> Materials for laser cutting

>> Applications for laser cutting

Clothing & Home Textiles

✔ Smooth and lint-free edge through heat treatment

✔ Conveyor system helps more efficient production for the roll materials

✔ High precision in cutting, marking, and perforating with fine laser beam

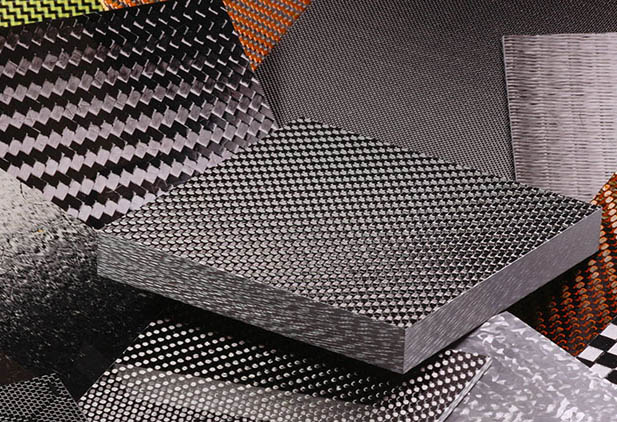

Composite Material

Engraving, marking, and cutting can be realized in single process

✔ MimoWork laser guarantees the exacting cutting quality standards of your products

✔ Fewer material waste, no tool wear, better control of production costs

✔ Ensures a safe working environment during operation

Automotive & Aviation

Your popular and wise manufacturing direction

✔ Smooth and lint-free edge through heat treatment

✔ High quality brought by fine laser beam and contact-less processing

✔ Greatly saving cost to avoid materials waste

Outdoor Equipment

The secret of exquisite pattern cutting

✔ Realize unattended cutting process, reduce manual workload

✔ More customization from high-quality value-added laser treatments like engraving, perforating, marking, etc

✔ Customized laser cutting tables meet requirements for varieties of materials formats

Learn more fabric laser cutting machine price

Add yourself to the list!

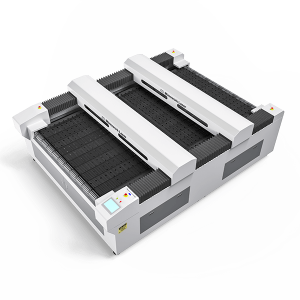

Laser Cutting Film

Positive Solution of Laser Cutting PET Film

Laser cutting polyester film is the typical applications. Due to the prominent polyester performance, it is widely applied on display screen, membrane switch overlaying, touchscreen and others. Laser cutter machine opposes excellent laser melting capability on the film to produce clean & flat cut quality at high efficiency. Any shapes can be flexibly laser cut after uploading the cutting files. For printed film, MimoWork Laser recommends the contour laser cutter which can realize the accurate edge cutting along the pattern with the help of the camera recognition system.

Besides that, for heat transfer vinyl, 3M® protective film, reflective film, acetate film, Mylar film, laser cutting and laser engraving are playing important roles in these applications.

film2

Video Display – How to Laser Cut Film

• Laser cutting transparency film

• Laser cutting printed film

Only need to upload the cutting file and set the laser parameter, the laser machine will start the non-contact cutting, with accurate cutting path and precise incision. Automatic feeding and conveying provide the a consistent and stable production for film laser cutting.

Any questions about laser cutting pet film?

Contact us

Recommended Film Cutting Machine

flatbed-laser-cutter-130

Flatbed Laser Cutter 130

• Laser Power: 100W/150W/300W

• Working Area: 1300mm * 900mm (51.2” * 35.4 ”)

Galvo-Laser-Engraver-Marker-40

Galvo Laser Marking Machine

• Laser Power: 180W/250W/500W

• Working Area: 400mm * 400mm (15.7” * 15.7”)

Upgrade Options:

Auto-Feeder

CCD Camera

Pick the laser machine and laser options that suit you!

Inquire us

MimoWork laser is aiming at solving the potential problems during your film manufacturing

and optimize your business throughout day-to-day execution!

Common Applications of Laser Cutting Film

• Window Film

• Nameplate

• Touch Screen

• Electrical insulation

• Industrial Insulation

• Membrane Switch Overlays

• Label

• Sticker

• Face Shield

• Flexible Packing

• Stencils Mylar Film

Material Properties of PET Film:

laser-cutting-pet-film

Polyester film is the main material among the all, often referred to as PET (Polyethylene Terephthalate), has outstanding physical properties for a plastic film. These include high tensile strength, chemical resistance, thermal stability, flatness, clarity, high-temperature resistance, thermal and electrical insulation properties.

Polyester film for packaging represents the largest end-use market, followed by industrial which includes flat panel displays, and electrical/electronic like reflective film, etc. These end uses account for almost the total global consumption.

How to choose a suitable film cutting machine?

Laser cutting PET film and laser engraving film are the two main usages of the CO2 laser cutting machine. As polyester film is a material that has a wide range of applications, in order to make sure that your laser system is ideally suited for your application, please contact MimoWork for further consulting and diagnosis. We believe that expertise with fast-changing, emerging technologies at the crossroads of manufacture, innovation, technology, and commerce are a differentiator.

We thinks what clients think, the urgency of urgency to act inside the interests of a customer position of basic principle, allowing for much better high quality, reduce processing costs, charges are additional reasonable, won the new and previous customers the support and affirmation for Factory made hot-sale China Flatbed for Cutting and Creasing Laser Cardboard Durable Fast Durable Optical Sensor Die Cutter, The concept of our organization is “Sincerity, Speed, Provider, and Satisfaction”. We are going to follow this concept and earn more and more customers’ satisfaction.

Factory made hot-sale China Cutter, Laminate, Wide selection and fast delivery for you! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!