How to Laser Cut Gear?

Laser cut gears offer precision, efficiency, and versatility for industrial and DIY projects.

This guide explores the key steps for laser cut tactical gear—from material selection to design optimization—ensuring smooth, durable gear performance. Whether for machinery, robotics, or prototypes, mastering laser-cutting techniques enhances accuracy and reduces production time.

Discover expert tips to avoid common pitfalls and achieve flawless results. Perfect for engineers, makers, and hobbyists alike!

Follow These Steps To Laser Cut Gear:

1. Design Smart: Use CAD software to create your gear design—focus on tooth profile, spacing, and load requirements. A well-thought-out design prevents performance issues later.

2. Prep for the Laser: Export your design as a DXF or SVG file. This ensures compatibility with most laser cutters.

3. Machine Setup: Import the file into your laser cutter’s software. Secure your material (metal, acrylic, etc.) firmly on the bed to avoid shifting.

4. Dial in the Settings: Adjust power, speed, and focus based on material thickness. Too much power can burn edges; too little won’t cut cleanly.

5. Cut & Inspect: Run the laser, then check the gear for precision. Burrs or uneven edges? Adjust settings and try again.

Laser Cutting Gear Has Several Notable Characteristics.

1. Pinpoint Accuracy: Even the most complex gear shapes come out perfect—no wobble, no misalignment.

2. Zero Physical Stress: Unlike saws or drills, lasers don’t bend or warp materials, keeping your gear’s integrity intact.

3. Speed + Versatility: Cut metals, plastics, or composites in minutes, with minimal waste. Need 10 gears or 1,000? The laser handles both effortlessly.

Precautions to Take When Using Laser Cut Gear:

1. Always wear laser-safe goggles—stray reflections can damage eyes.

2. Clamp materials tightly. A slipping gear = ruined cuts or worse, a damaged machine.

3. Keep the laser lens clean. Dirty optics lead to weak or inconsistent cuts.

4. Watch for overheating—some materials (like certain plastics) can melt or emit fumes.

5. Dispose of waste properly, especially with materials like coated metals or composite

Advantages of Using A Cloth Laser Cutting Machine for Gear

Precise Cutting

Firstly, it allows for precise and accurate cuts, even in intricate shapes and designs. This is especially important for applications where the fit and finish of the material are crucial, such as in protective gear.

Fast Cutting Speed & Automation

Secondly, a laser cutter can cut Kevlar fabric which can be fed & conveyed automatically, making the process faster and more efficient. This can save time and reduce costs for manufacturers who need to produce large quantities of Kevlar-based products.

High Quality Cutting

Finally, laser cutting is a non-contact process, meaning that the fabric is not subjected to any mechanical stress or deformation during cutting. This helps to preserve the strength and durability of the Kevlar material, ensuring that it retains its protective properties.

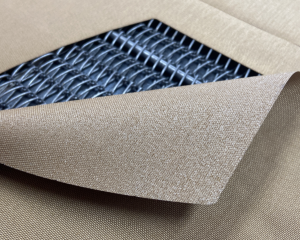

The Cordura Cut By Laser Machine

Learn More about How to Laser Cut Tactical Gear

Why Choose CO2 Laser Cutter

Here is a comparison about Laser Cutter VS CNC Cutter, you can check out the video to learn more about their features in cutting fabric.

Related Materials & Applications of Laser Cutting

Recommended Fabric Laser Cutter

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Software | Offline Software |

| Laser Power | 100W/150W/300W |

| Laser Source | CO2 Glass Laser Tube or CO2 RF Metal Laser Tube |

| Mechanical Control System | Belt Transmission & Step Motor Drive |

| Working Table | Honey Comb Working Table / Knife Strip Working Table / Conveyor Working Table |

| Max Speed | 1~400mm/s |

| Acceleration Speed | 1000~4000mm/s2 |

| Working Area (W * L) | 1600mm * 3000mm (62.9’’ *118’’) |

| Laser Power | 150W/300W/450W |

| Working Area (W * L) | 1600mm * 1000mm (62.9” * 39.3 ”) |

| Laser Power | 100W/150W/300W |

FAQs

Uncoated Cordura should be carefully sealed at the edges with a lighter or soldering iron before processing to prevent fraying.

Limited Material Thickness – Lasers are limited as to the thickness they can cut. The maximum is typically 25 mm. Toxic Fumes – Certain materials produce dangerous fumes; therefore, ventilation is required. Power Consumption – Laser cutting consumes large amounts of power.

Any Questions about How to Cut Gear with Laser Cutting Machine?

Post time: May-15-2023